8

WARNING: use toughened glass only with a minimum

thickness of 6mm (¼”) with rounded/polished edges. Take

care when handling glass. Always use suitable gloves, eye

protection and protective clothing.

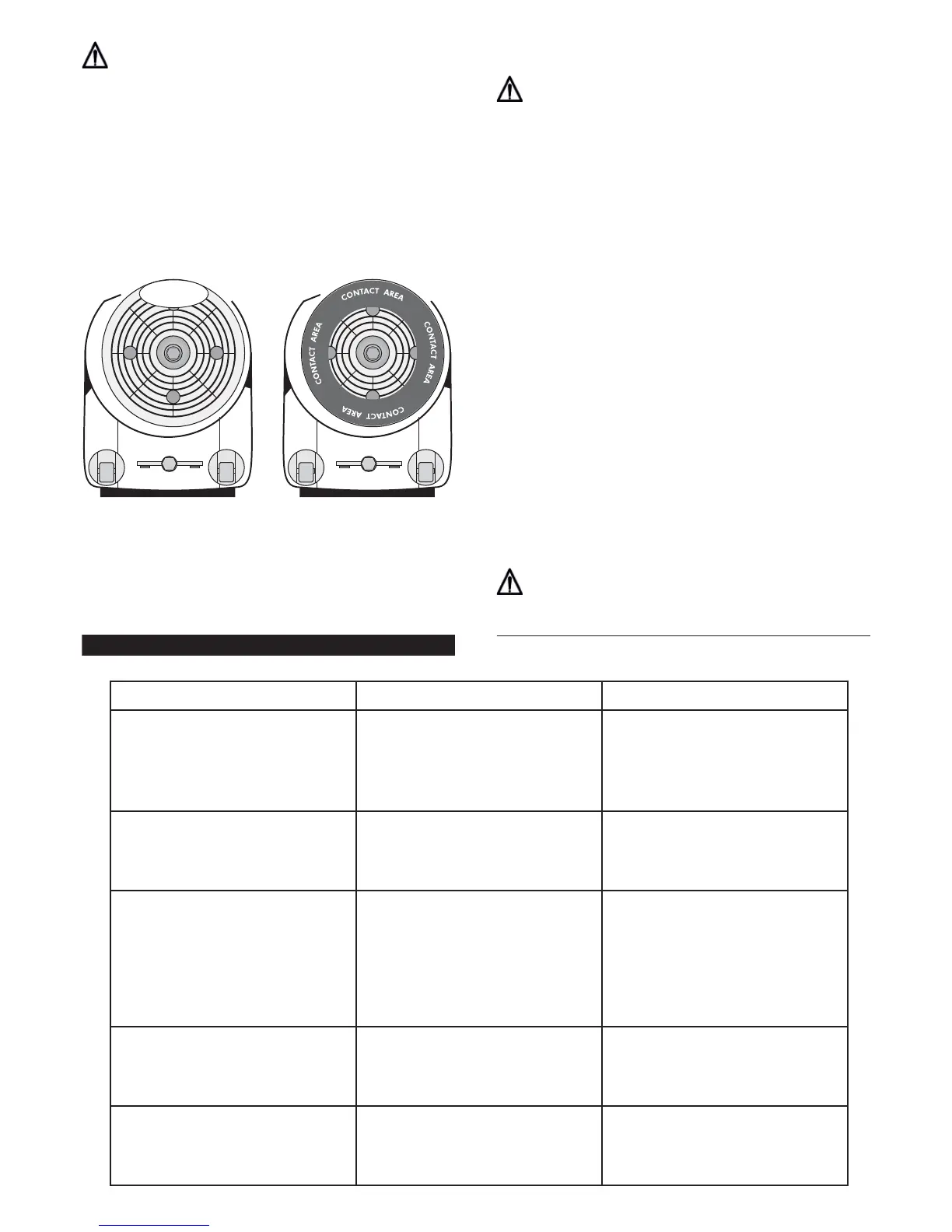

2 To adjust the castors loosen the two castor lock nuts using the

special tool Part No. 011720 and 5mm ball allen key. Adjust

the castors and check the contact area on the sanding pad.

When the contact area is correct tighten the two castor lock

nuts securely. Use a suitable thread lock compound. Finally

check the contact area is still correct after tightening the castor

lock nuts.

4. Trim the sanding pad as detailed above.

CONTACT AREA

Sanding Pad Contact Area Sanding Pad Trim Area

Electrical Testing

CAUTION: testing for electrical safety should only be

undertaken by a competent person and all results recorded.

Do not exceed 1250 volt insulation test duration of 3

seconds.

1. Examine the power cable for damage. If the outer insulation

shows the slightest of abrasions or the inner conductors are

exposed then the cable must be replaced. The cable must not

be repaired with tape or insulation sleeve.

2. Open and check the mains plug for condition, loose

connections, damaged wires, etc.

3. Remove the four Screws Ref.1 and lift off the Cover Motor

Ref.4 to check the switch, connections, leads etc. Pay special

attention to any gaskets, ‘O’ rings and seals intended to

exclude dust from the switch and switch housing area. These

must be maintained in good condition.

Carefully brush and vacuum clean the switch and brush block

assembly and inside the cover motor.

4. Refit the cover motor taking care not to trap any leads.

5. Using a piece of insulation tape or a small soft wedge lock the

bias off switch in the ‘ON’ position.

6. Use the standard procedure test for electrical safety

(Class I Earthed Appliances [U.K.]). Do not exceed 1250 volt

insulation test duration of 3 seconds.

7. Record the test results.

8. Complete a functional (run) test and record results.

CAUTION: when undertaking a functional (run) test make

sure the machine is secure. Remember the sanding disc will

rotate.

FAULT FINDING

FAULT CAUSE ACTION

The machines does not run. The power cable is not connected to the

power supply.

The motor brushes are worn

The voltage is too low.

Connect the power cable to the power

supply.

Replace the motor brushes.

Check the main power complies with the

machine’s serial plate data.

The machine runs slow. The voltage is low. Check the supply voltage.

If an extension lead is being used it is

undersized and/or it is coiled.

The machine will not pickup dust. The dust bag is full.

There is an obstruction in the dust pickup.

A motor brush is not making

Replace the paper dust bag or dust or

empty the cloth dust bag.

Disconnect the machine from the power

supply, turn the machine over and check

for obstruction.

Check and refit or replace the motor

brushes and/or the brush springs.

The machine does not sand evenly The sanding pad is damaged.

The castors are out of adjustment.

Check and service/replace the sanding

pad.

Check and adjust the castors.

The sander scores or burns the wood. The machine is not being operated

properly.

Read the instructions, do not apply

pressure when sanding.

Loading...

Loading...