Sanding Drum.

1. Check that power supply is disconnected. Tilt the

machine back and rest the handle on the floor.

Open the drum guard and examine the drum

cover. A damaged or worn cover must be

replaced to maintain machine performance. A

damaged or worn cover can result in poor

sanding with subsequent damage to the floor

surface and can be dangerous in operation. A

cover that is worn to 1/4“ (6mm) or less in

thickness must be replaced.

2. To replace the drum cover see the detailed

instructions included in each genuine Hiretech

Drum Cover Kit Ref.167 Part # 162312. The use

of an impact screwdriver may assist.

3. It is recommended that at each service interval

the drum cover is checked and trimmed

(dressed) if necessary to provide a true uniform

diameter.

4. First check that the rear castors are properly

adjusted. Remove the 4 Screws Ref.83 and the

Belt Guard Ref.81. Check that the factory mark

is present and aligned on the rear castor adjuster

Ref.64 and main frame. Adjust as necessary by

loosening the two clamp Bolts Ref.65 and

adjusting the cam.

If the machine has no factory mark on the

adjuster and main frame then it is a later type

machine that uses a concentric support instead

of an adjuster. No adjustment is required.

Note: On earlier models the line stamped on the

adjuster and main frame has been set in the factory at

the time of manufacture. Never change, deface or

alter this line.

5. Fit a sheet of fine grit abrasive paper (120 grit),

abrasive side up on to a level floor surface.

Remove any abrasive paper from the drum and

re-tighten the clamp bar screws. Make sure the

clamp bar screws are tight.

Position the floor sander over the abrasive paper

and connect the power cable to the power

supply. Tip the floor sander back to raise the

sanding drum off the floor and switch on.

Gently lower the floor sander so the sanding

drum 'just' touches the abrasive paper. Hold the

sander in position for a few seconds then tip back

and switch off.

Disconnect the power cable and tip the floor

sander back so that it rests on it's handle. Lift the

drum guard and check the condition of the drum

cover. If it is uniform an even surface will be

witnessed, if not, continue to dress the drum until

all high and low spots are removed. Take care

not to remove too much material as this will

reduce the life of the drum cover.

6. When a uniform surface is achieved it is

advisable to slightly ‘feather’ both edges of the

drum cover. Switch off and disconnect the power

cable from the power supply. Tilt the machine

back and lift the drum guard to expose the drum

cover. Using a medium to fine grit abrasive

paper carefully feather the edge of both sides of

the drum cover by holding the abrasive paper

against the edge and rotating the drum. Be

careful not to trap your fingers. The softer edge

provided will help prevent ‘cut’ lines witnessed

on the floor surface when sanding particularly in

softer woods. Always feather the edges of a new

drum cover.

WARNING - the sanding drum and drum

cover must be correctly adjusted and

maintained to ensure the best sanding

performance. Failure to do so can result

in damage to the floor surface and can

be dangerous.

Care of Motor

1. The motor must be kept free from grease and

dust. use high pressure air to blow theDO NOT

motor clean. Use a vacuum and soft brush to

clean the motor and brush block assembly.

2. The motor brushes must be checked regularly,

inspect the brushes every three months or every

300 hours from new and then every 100 hours of

use thereafter.

The 8 Multi-Speed has a run time clock builtHT

into the Multi-Speed Control Unit to assist in

scheduled servicing. See page 8 for information.

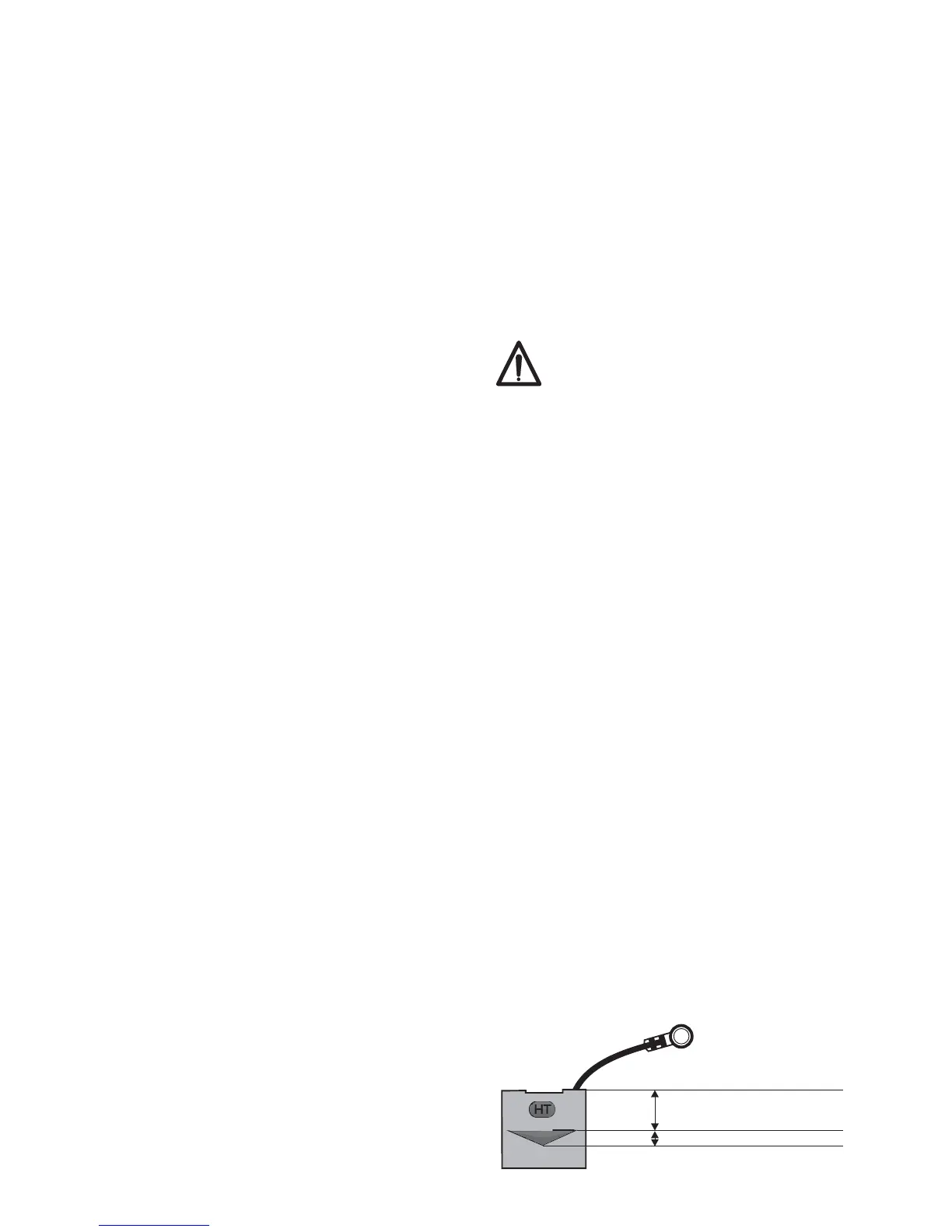

3. Replace motor brushes when any oneALL FOUR

brush has worn to 12mm ( / ”) or less in length.

15

32

Brushes slide freely in the brush holders.MUST

Brush ware is also indicated by the ‘triangular’

ware indicator stamped on genuine Hiretech

motor brushes marked with the symbol. SeeHT

illustration below.

When any one motor brush is worn down to the

ware indicator inspect the brushes ever 100hrs.

Replace all four motor brushes when any ONE

(1) motor brush is worn down to the minimum

brush length as indicated by the bottom of the

triangle stamped on the motor brush.

10

HT

HT MOTOR BRUSH8

Minimum Brush Length

12mm ( / ”)

15

32

Ware Indicator

Loading...

Loading...