●Installing Precautions 4-3

(14) If you try to fix the print head with a magnetic substance (such as iron), the cover switch will

malfunction resulting in an "Cover Open" error.

This, you must only use nonmagnetic resins or metals for fixing the print head.

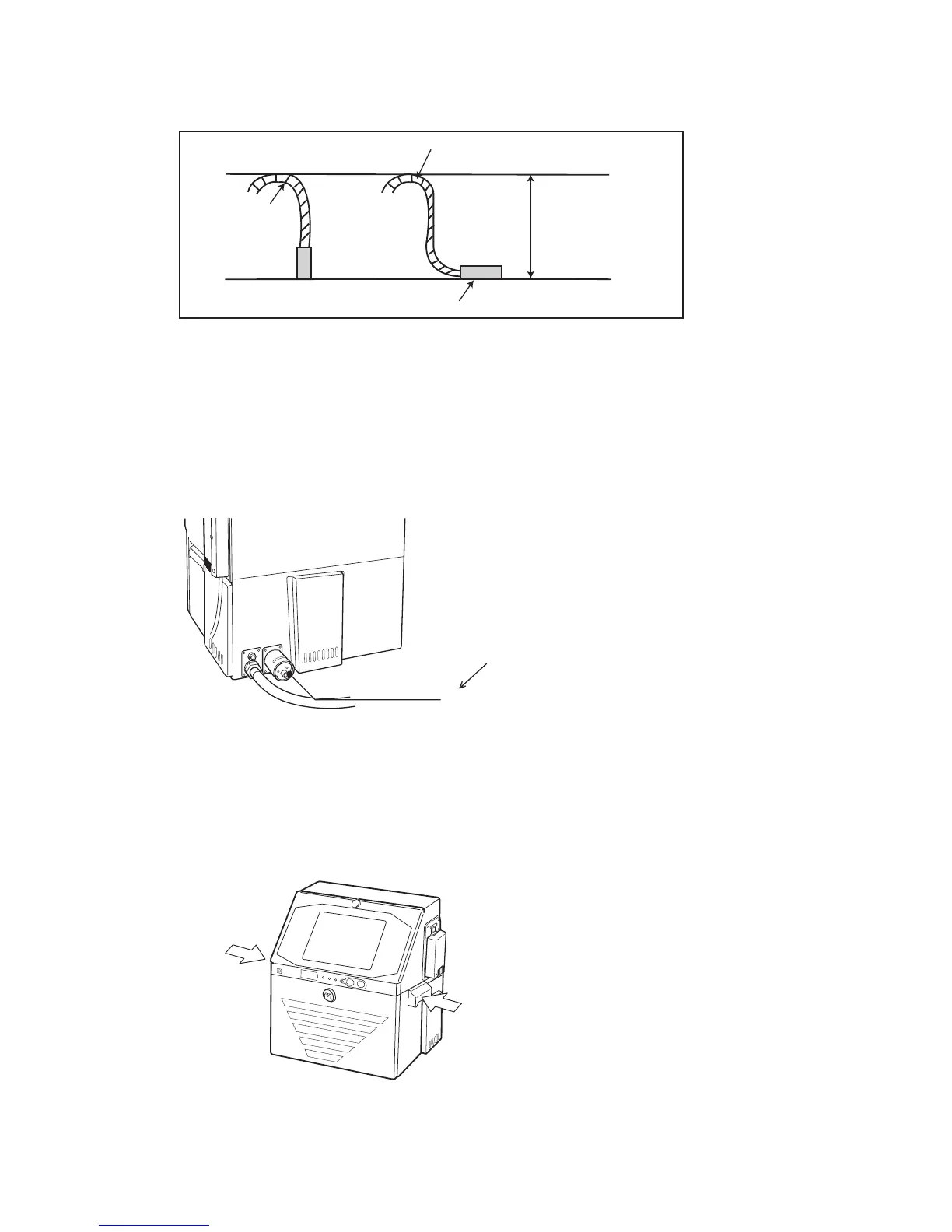

(15) In the case of carrying the printer proper, use the handles in the drawing below.

Print head

Print head cable

Bend R

0.5m

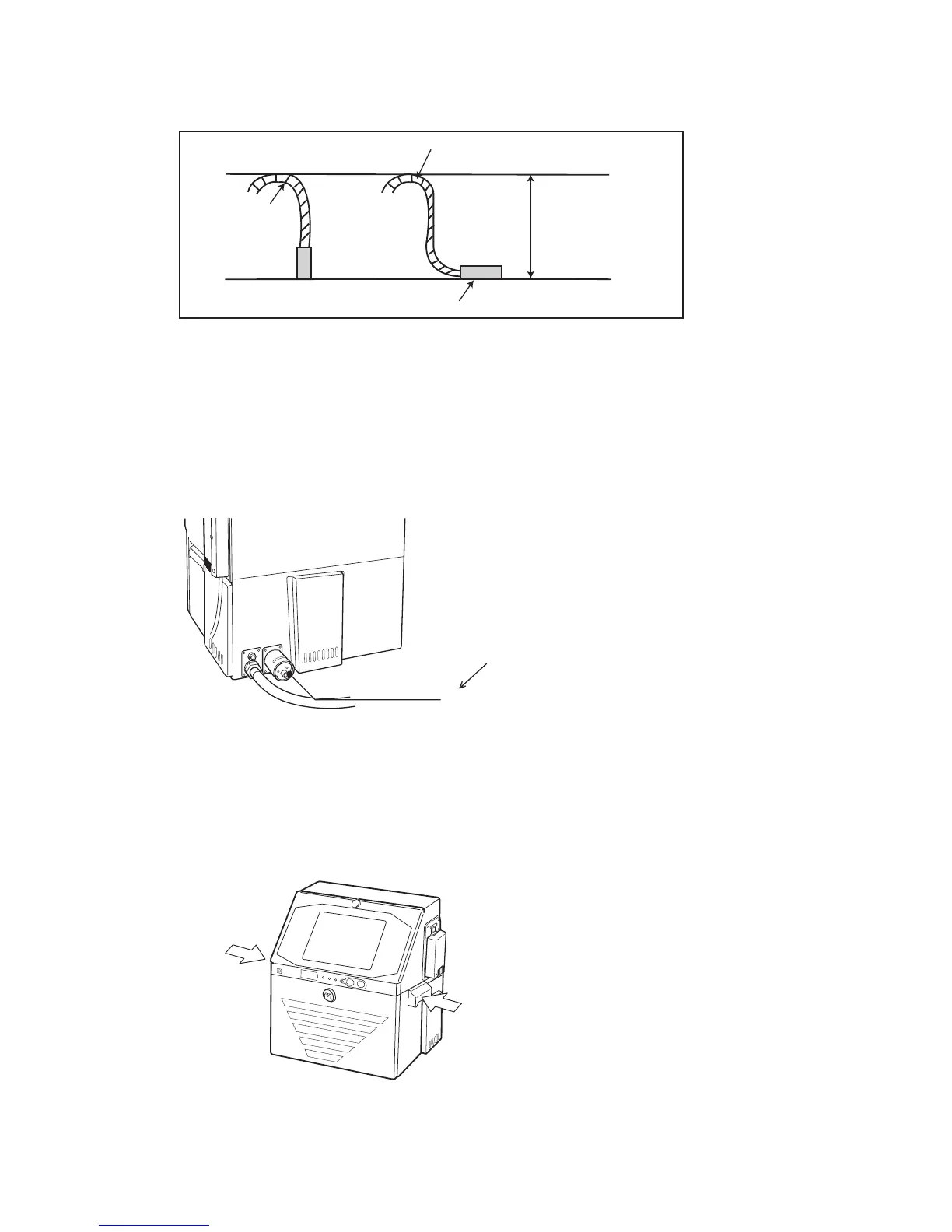

(10) When using the printer for upward or lateral printing, ensure that the rising print head cable upper end

is positioned not more than 0.5 m above the print head.

(11) If you fixed the print head, ensure that the minimum bend radius of the print head cable is at least 150 mm.

Handle the headcable with care when wiring it.

If the minimum bend radius is less than 150mm, the tubes and wires inside the headcable might be broken.

(12) The ink stream may bend for some reason or other (due, for instance, to dirt).

The facilities positioned in the direction of ink ejection should be partially covered as needed to avoid ink

accumulation.

(13) When connecting an exhaust duct to the printer, install a damper and adjust the wind velocity at the intake

port to 0.3 to 0.5 m/s. (Use an anemometer for verification. If the wind velocity is too high, the makeup

consumption increases.)

Loading...

Loading...