OM-2244 / Operation and Maintenance Manual

DCS-600/ Series 500082 / Solid State Transformer-Rectifiers

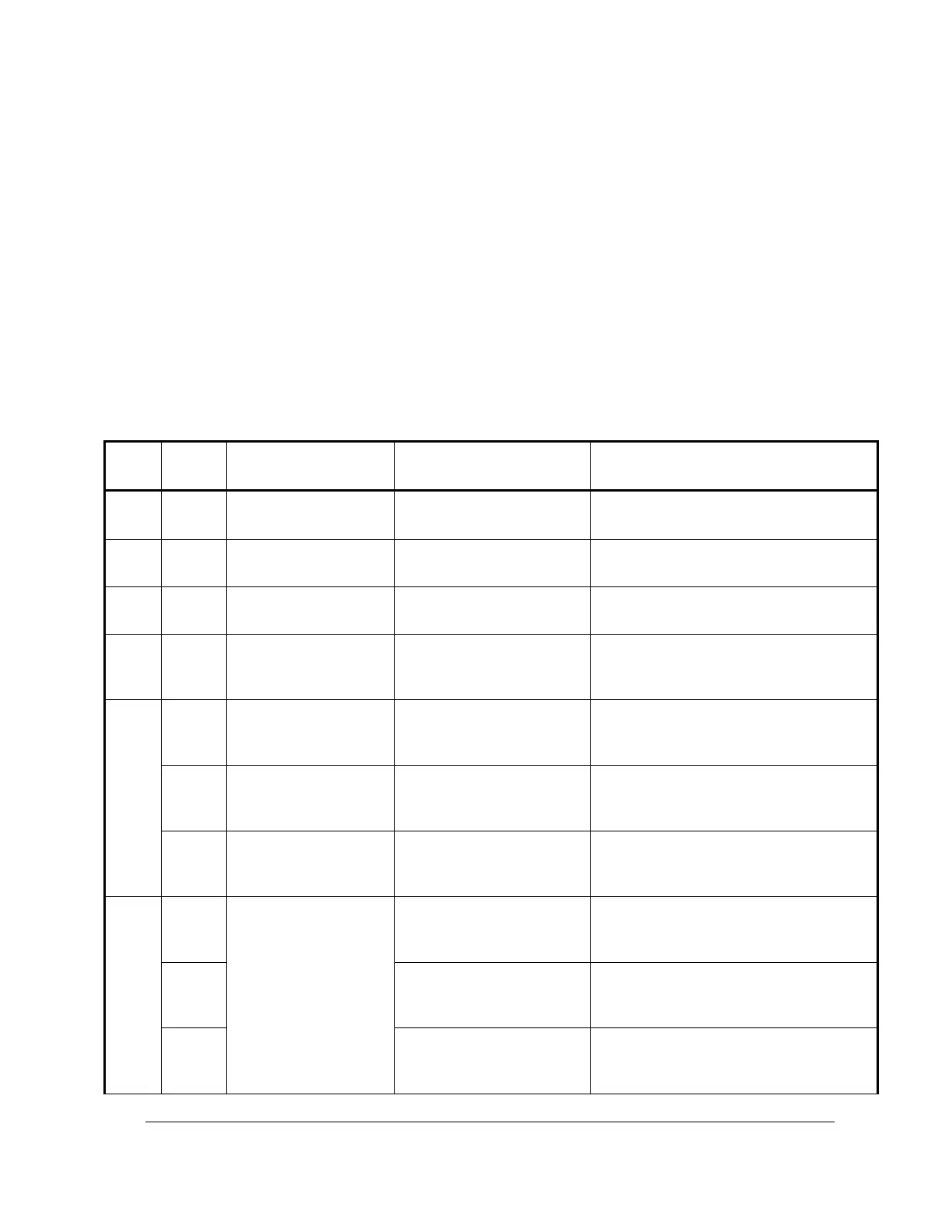

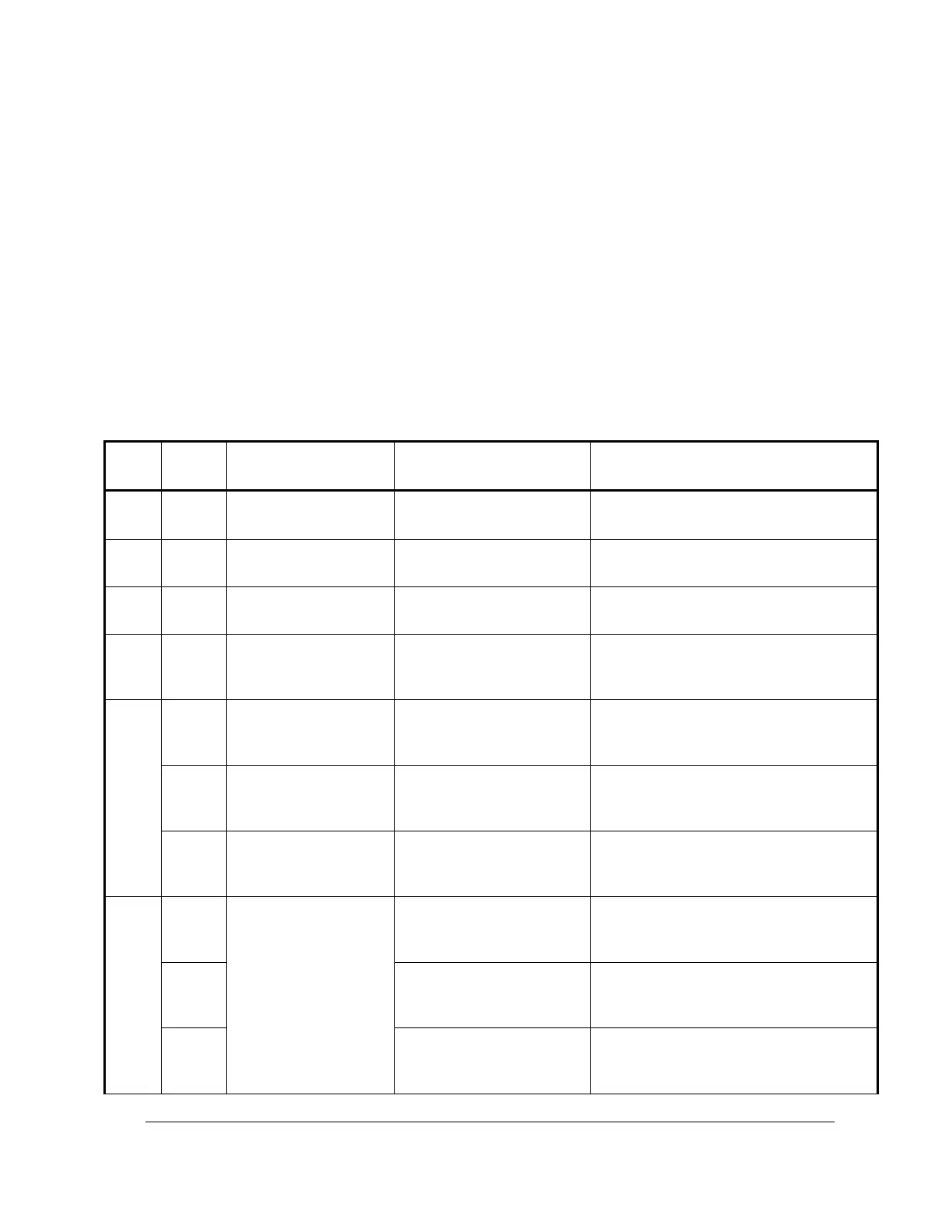

3) Test Procedure

Follow the table steps in this section to verify that the PC board is functioning properly. If the voltage

readings to the PC board common are not within specification, attempt to correct the reading by adjusting

the applicable control. Be certain the operating conditions are exactly as stated in the table.

If the board does not adjust, check the leads, fuses (F2-F7), and connectors. If no external problems are

found, the PC control board is faulty. Replace it with a known good board.

After replacing the board, recheck the voltages. In some cases, minor adjustments may be required for

optimum calibration. If the replacement board shows the same magnitude of error and lack of adjustment

control, it is possible that the control board is not at fault. The voltages in the following table are all

referenced to pc board common, which is Test Point 3 (TP3) and Test Point 15 (TP15). Connect the

negative voltmeter lead to either of those test points.

Checks (+) voltage regulator output set

by U4.

Checks (-) voltage regulator output set

by U5.

Checks unregulated control voltage

needed for 1 and 2

Checks gate pulse timer volts supply

set by CR9

Checks gate pulse timer operation

before phase balancing and

amplification

Checks gate pulse timer operation

before phase balancing and

amplification

Checks gate pulse timer operation

before phase balancing and

amplification

With a 100 A load,

adjust R9 and R10

carefully for lowest

ripple voltage

(typically 100 to 160

mV).

-8.2 VDC ± 10%

(measured with no load)

Checks gate pulse timer operation and

balance adjustment

-8.2 VDC ± 10%

(measured with no load)

Checks gate pulse timer operation and

balance adjustment

-8.2 VDC ± 10%

(measured with no load)

Checks gate pulse timer operation and

balance adjustment.

Loading...

Loading...