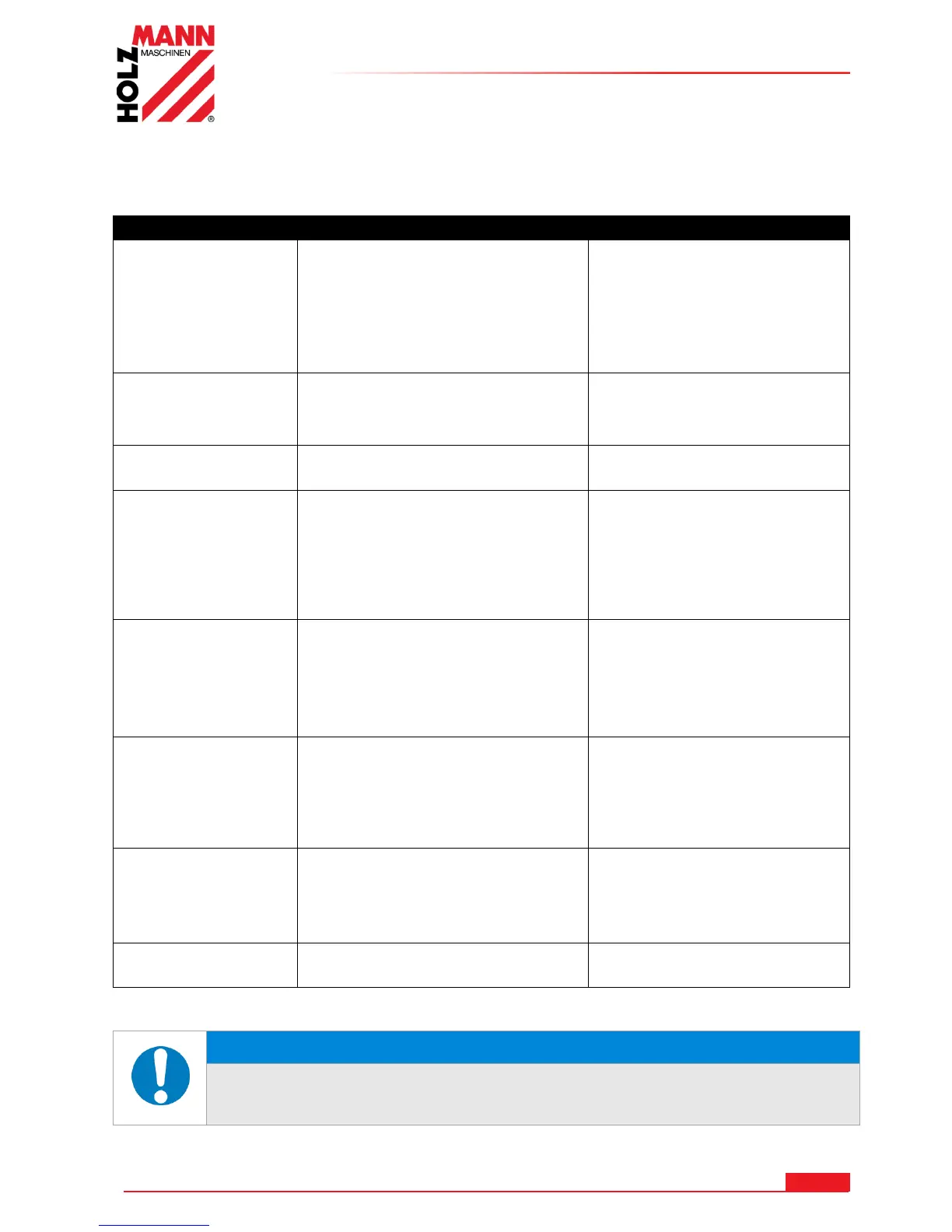

TROUBLE SHOOTING

HOLZMANN MASCHINEN GmbH www.holzmann-maschinen.at 31

TK 255

18 TROUBLE SHOOTING

BEFORE YOU START WORKING FOR THE ELIMINATION OF DEFECTS, DISCONNECT THE

MACHINE FROM THE POWER SUPPLY.

Motor cord or wall cord is not

plugged in.

Circuit fuse is blown.

Circuit breaker is tripped.

Cord or switch is damaged

Overload protection activated

Plug in motor cord or wall cord.

Replace circuit fuse.

Reset circuit breaker.

Have the cord or switch

replaced.

See capture overload protection

Rip fence does not

move smoothly.

Rip fence not mounted correctly.

Rails are dirty or sticky.

Clamp screw is out of adjustment.

Clean and wax rails.

Adjust clamp screw.

Rip fence does not

lock at rear.

Clamp screw is out of adjustment.

Cutting binds or

burns work.

Working is fed too fast.

Rip fence is misaligned.

Spreader is out of alignment.

Wood is warped.

Replace or sharpen blade.

Slow the feed rate.

Align the rip fence.

Replace the wood.Always cut

with convex side to table

surface.

Wood edges away

from rip fence when

ripping.

Saw does not make

accurate 90ºor 45º

cuts.

Ripping fence is misaligned.

Positive stops inside cabinet need

adjusting(Bevel Cuts).

Miter gauge is misaligned(Miter

Cuts) .

Check and adjust the rip fence.

Adjust positive stops.

Adjust the miter gauge.

Blade is wrong type for cut being

made.

Blade is mounted backwards.

Clean, sharpen, or replace

blade.

Replace with correct type.

Remount blade.

Blade does not

lower when turning

height /bevel

adjusting

handwheel.

Locking lever is not at full left

position.

Move locking lever to left.

Blade not proper for rip out.

Change blade; rip blade typically

has fewer teeth.

MANY POTENTIAL SOURCES OF ERROR CAN BE CLEARED BY THE EXPERTLY

CONNECTION TO THE ELECTRICITY GRID.

Should you in necessary repairs not able to properly to perform or you have

not the prescribed training for it always attract a workshop to fix the problem.

Loading...

Loading...