BCU 370 · Edition 01.19 6

VG

IC 20

BVA

GIK

L1

V1

4

DG

min

9 3

VG..L

V2

5293130 32

23

21

24

13

17

18

19

20

26

28

25

BCU 370..I1

DL

DL

7

DG

M

22

UVS

90° ➔ 0

0 ➔ 90°

VG

IC 20

B VA

GIK

L1

V1

4

DG

min

9 3

VG..L

V2

5 32

23

21

24

13

17

18

19

20

25

BCU 370..I1..D3

DL

DL

7

DG

M

22

DG

11

DG

p

u

/2

UVS

29 3130

26

28

90° ➔ 0

0 ➔ 90°

V1

4

VG..L

V2

5

DG

11

DG

p

u

/2

Application

1.1 Applications example

1.1.1

Modulating-controlled forced

draught burner

The BCU 370 controls the fan and

moves the butterfly valve to pre-

purge and ignition position. It issues

the enable signal to the control sys-

tem after start-up of the burner.

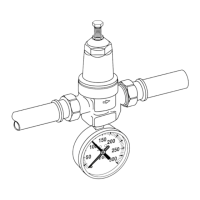

1.1.2

Modulating-controlled forced

draught burner with tightness

control

In addition to controlling the forced

draught burner, the burner control

unit also monitors the fail-safe

function of the two solenoid valves

for gas via the gas pressure switch

DG which is set to p

u

/2.

Parameter 27 = 1: V2 is “ON” during

burner operation.

Loading...

Loading...