BCU 460, BCU 465 · Edition 11.19 10

Application

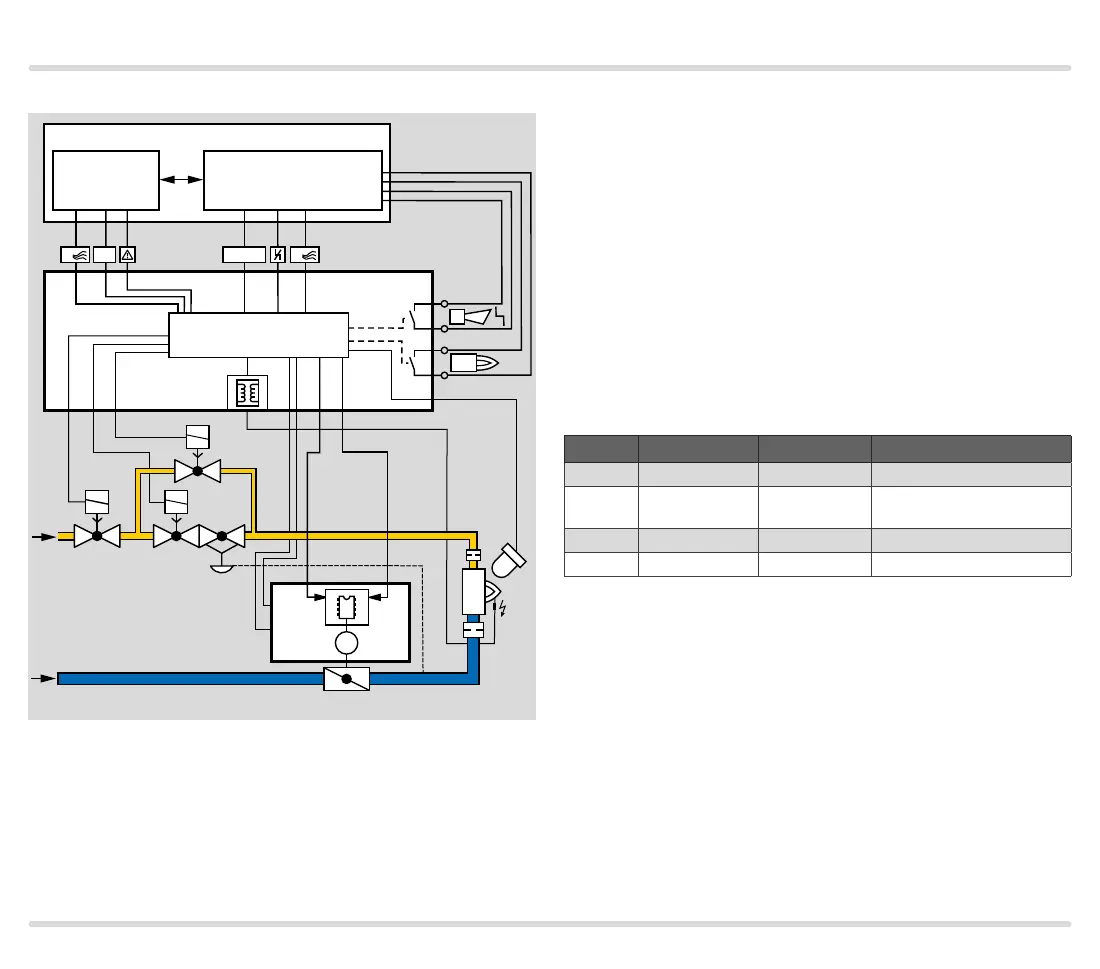

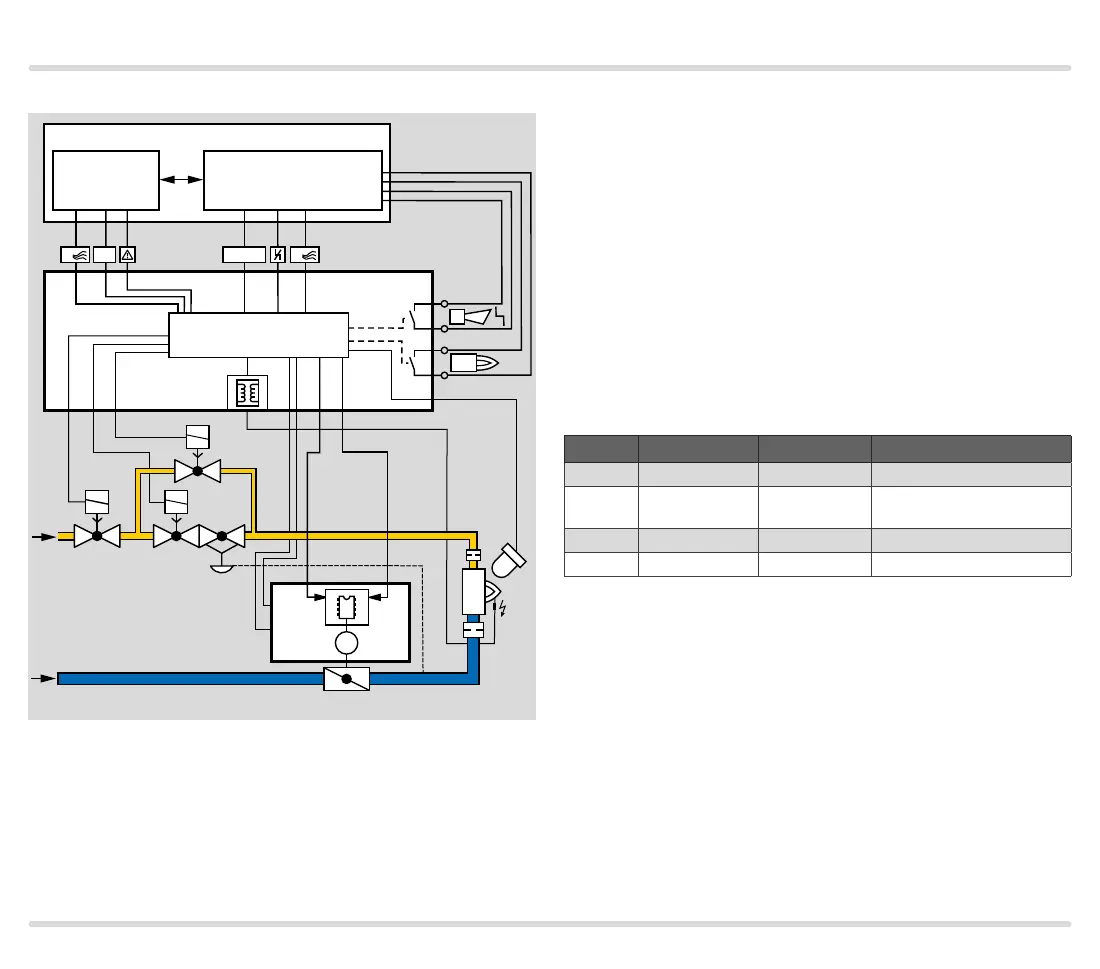

1.1.3 Staged control

VAS VAG

V1

V2

V3

UVS

VAS 1

BCU 460..F1

60 61 62 65 66

22

3 6

µC

81

82

95

96

35

2

Process control (PCC)

P

4

A

1

Start

1

HT

40 41

BVA

IC 40

4

12

16

DI 1

7

DI 2

M

µC

FCU 500 PLC

The central control system starts the pre-purge. Input

DI2 is activated via the output at terminal 66 of the

BCU and the butterfly valve BVA is set to the pre-purge

position.

In the event of a temperature demand, the burner con-

trol unit BCU activates input DI1 via the output at ter-

minal 65 and moves the butterfly valve to the ignition

position (condition: the IC40 must have reached the

ignition position on the instant of ignition). The burner

starts.

The burner application “Burner 1 with pilot gas” (pa-

rameter A078=1) is selected so that the burner can be

started with a limited start fuel flow rate.

To activate the high-fire rate, DI2 is actuated via the air

valve output at terminal66 of the BCU.

The butterfly valve moves cyclically between the high-

fire and low-fire rate position, see page110 (Operat-

ing mode 11).

DI 1/V1 DI 2/Air valve IC 40 position Valve position

Off Off closed Closed

On Off low

Ignition position/Low-fire

rate

On On middle High-fire rate

Off On high Pre-purge

Loading...

Loading...