BCU 460, BCU 465 · Edition 11.19 11

Application

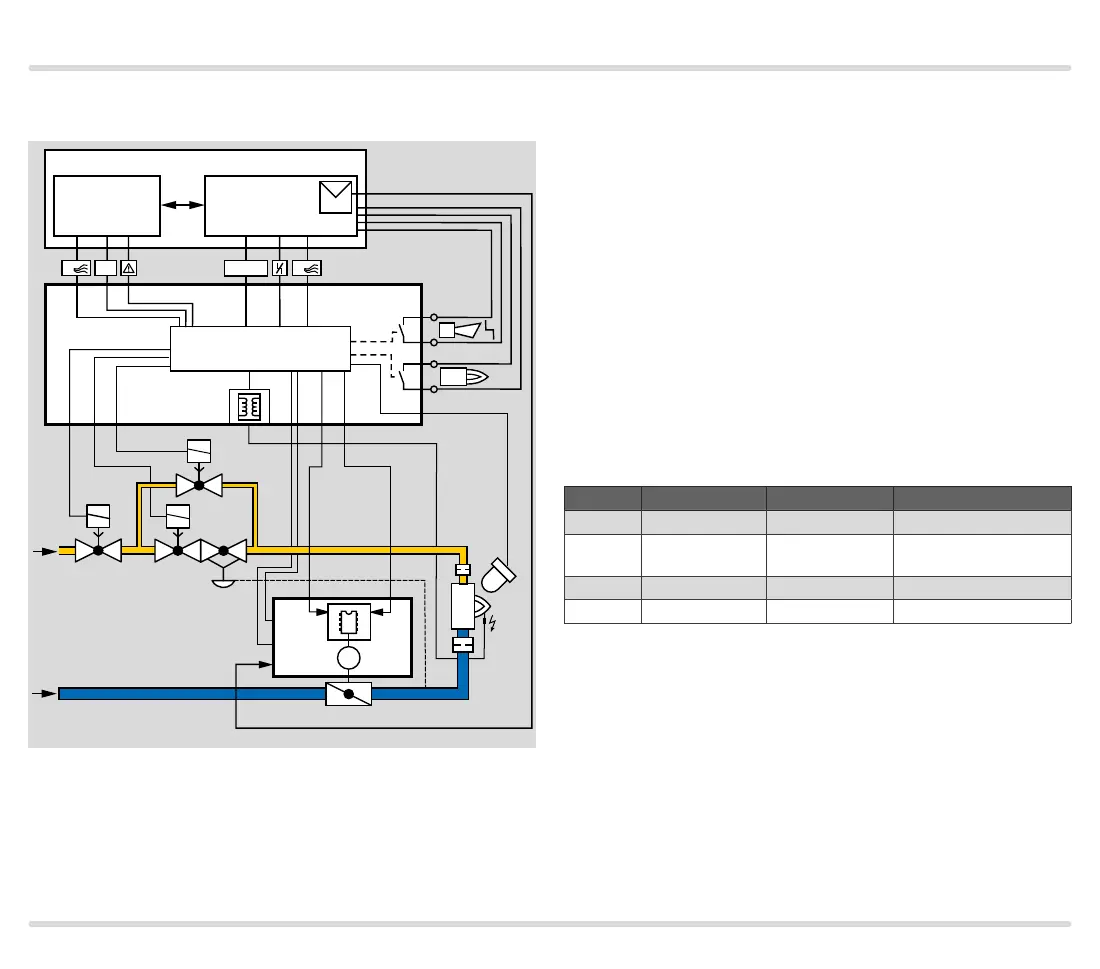

1.1.4 Modulating control with defined ignition

position

VAS VAG

V1 V2

V3

UVS

VAS 1

BCU 460..F1

60 61 62 65 66

22

3 6

µC

81

82

95

96

35

2

Process control (PCC)

P

4

A

1

Start

1

HT

40 41

BVA

IC 40

4

12

16

DI 1

7

DI 2

M

µC

18

IN

mA

FCU 500 PLC

The central control system starts the pre-purge. Input

DI2 is activated via the air valve output of the BCU and

the butterfly valve BVA is set to the pre-purge position.

In the event of a temperature demand, the burner con-

trol unit BCU activates input DI1 via the output at ter-

minal 65 and moves the butterfly valve to the ignition

position (condition: the IC40 must have reached the

ignition position on the instant of ignition). The burner

starts.

The burner application “Burner 1 with pilot gas” (pa-

rameter A078=1) is selected so that the burner can be

started with a limited start fuel flow rate.

During operation, the BCU activates DI1 and DI2 using

outputs 65 and66. This enables the analogue input IN

on the actuator IC40. Depending on the capacity de-

mand of the temperature controller, the butterfly valve

BVA moves steplessly between the low-fire rate and the

high-fire rate to the position specified by the analogue

input IN, see page110 (Operating mode 27).

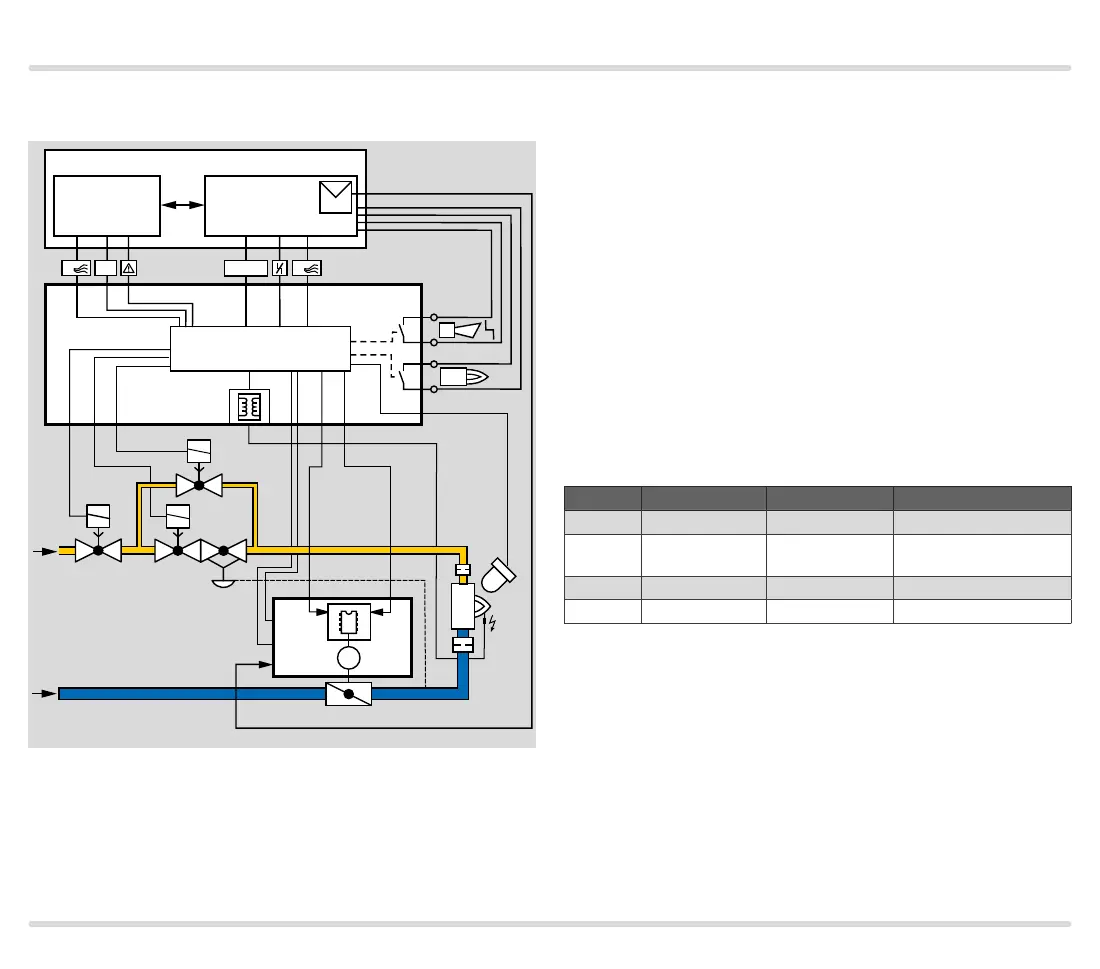

DI 1/V1 DI 2/Air valve IC 40 position Valve position

Off Off closed Closed

On Off low

Ignition position/Low-

fire rate

On On analogue chart 1 In acc. with chart 1

Off On high Pre-purge/High-fire rate

Loading...

Loading...