BCU 460, BCU 465 · Edition 11.19 6

Application

1 Application

The next-generation burner control unit BCU460/465

unites the components of automatic burner control

unit, ignition transformer, Manual/Automatic mode,

display of operating and fault statuses and a user inter-

face (HMI) in a compact metal housing. It replaces the

previous product line with the same name. It is suitable

for almost every conceivable multiple burner applica-

tion in the metal, ceramics, food and automotive indus-

tries.

It can be used for directly ignited industrial burners of

unlimited capacity. The burners may be modulating-

controlled or stage-controlled. Installation in the imme-

diate vicinity of the burner being monitored simplifies

system integration.

On industrial furnaces, it reduces the load on the cen-

tral furnace control by taking over tasks that relate to

the burner, for example it ensures that the burner ig-

nites in a safe condition when it is restarted.

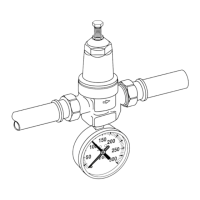

The air control on the BCU..F1 or F3 assists the furnace

control for cooling, purging and capacity control tasks.

The burner control unit has an interface via which an air

valve or actuator can be controlled for staged or modu-

lating burner capacity control.

The program status, device parameters, error codes,

statistics and level of the flame signal can be read eas-

ily and conveniently on the four-digit device display.

The burner can be controlled manually for commission-

ing, maintenance and diagnostic purposes.

Energy management using phase reduces the instal-

lation and cabling costs. The valves and ignition trans-

former are powered by phaseL1/the voltage supply for

the BCU instead of the safety interlocks.

The monitored outputs for the actuator and valve are

housed in the plug-in power module LM400. This can

easily be replaced if necessary.

▼

Loading...

Loading...