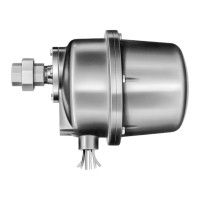

C7961E,F DYNAMIC SELF-CHECK ULTRAVIOLET FLAME DETECTOR

65-0267-09 4

Temperature

Install the C7961 where the ambient temperature (outside the

case) stays within the ambient operating temperature ratings.

To keep the C7961 below its maximum rating, it may be

necessary to add additional insulation between the wall of the

combustion chamber and the detector. A shield or screen can

be added to reflect radiated heat away from the detector. If the

detector continues to get too hot, cooling is necessary. Refer to

the Sight Pipe Ventilation section.

Vibration

If the C7961 is subject to excessive vibration, use a special

123539 Antivibration Mount. If you use this mount, install it

before you position and sight the detector.

Clearance

Make sure there is enough room to easily mount the sight pipe,

detector, and all required fittings, and to remove the detector

for troubleshooting and servicing.

Radiation Sources (Other than

Flame)

Examples of radiation sources (other than flame) that could

actuate the detection system:

Ultraviolet sources:

Hot refractory above 1800°F (982°C).

Spark:

— Ignition transformers.

— Welding arcs.

— Lightning.

Welding flames.

Bright incandescent or fluorescent artificial light.

Solar radiation.

Gas lasers.

Sun lamps.

Germicidal lamps.

Bright flashlight held close to the sensing tube.

Gamma ray and X-ray sources:

The C7961 is immune to x-ray exposure.

Except under unusual circumstances, none of these sources

except hot refractory and ignition spark would be present in or

near the combustion chamber.

The detector can respond to hot refractory above 1800°F

(982°C) if the refractory surface represents a significant

percentage of the detector field of view. If the temperature of

the hot refractory causes the flame relay (in the flame

safeguard control) to pull in, re-aim the sight pipe so the

detector views a cooler area of the refractory.

Ignition spark is an intense source of ultraviolet radiation.

When installing the detector, make sure it does not respond to

ignition spark.

Single Burner Requirements

The detector must have an unobstructed view of a steady part

of the flame it is supervising. This requires a proper sighting

angle and minimized ultraviolet radiation attenuation effects.

However, when supervising only one burner, sighting

requirements are simplified.

Sighting Angle (Fig. 3)

The first 30 percent of a flame closest to the burner nozzle (the

flame root) emits the most ultraviolet energy. Also, if the

detector sights the flame at an angle instead of

perpendicularly, it views more flame depth. Therefore, the best

sighting angle is nearly parallel to the axis of the flame,

permitting the detector to view a large portion of the first 30

percent of the flame closest to the burner nozzle, as illustrated

in Fig. 3.

Low angle sighting permits the detector to view a greater depth

of flame, thus reducing the effects of instabilities in the flame

pattern. Also, the environment near the burner nozzle is

usually cleaner than at any other part of the combustion

chamber. This provides a clearer line of sight and can keep the

viewing window cleaner, thus reducing the maintenance

required.

Fig. 3. Detector sighting angle.

NOTE: When possible, it is desirable to tilt the detector

and sight pipe downward to prevent the buildup

of soot in the pipe or on the viewing window.

DETECTOR IN GOOD

SIGHTING POSITION

(LOW ANGLE SIGHTING)

FLAME DEPTH-

ANGLE VIEW

BURNER

NOZZLE

DETECTOR IN POOR

SIGHTING POSITION

FLAME DEPTH-

PERPENDICULAR VIEW

UNBURNED FUEL

M1956A

Loading...

Loading...