C7961E,F DYNAMIC SELF-CHECK ULTRAVIOLET FLAME DETECTOR

3 65-0267-09

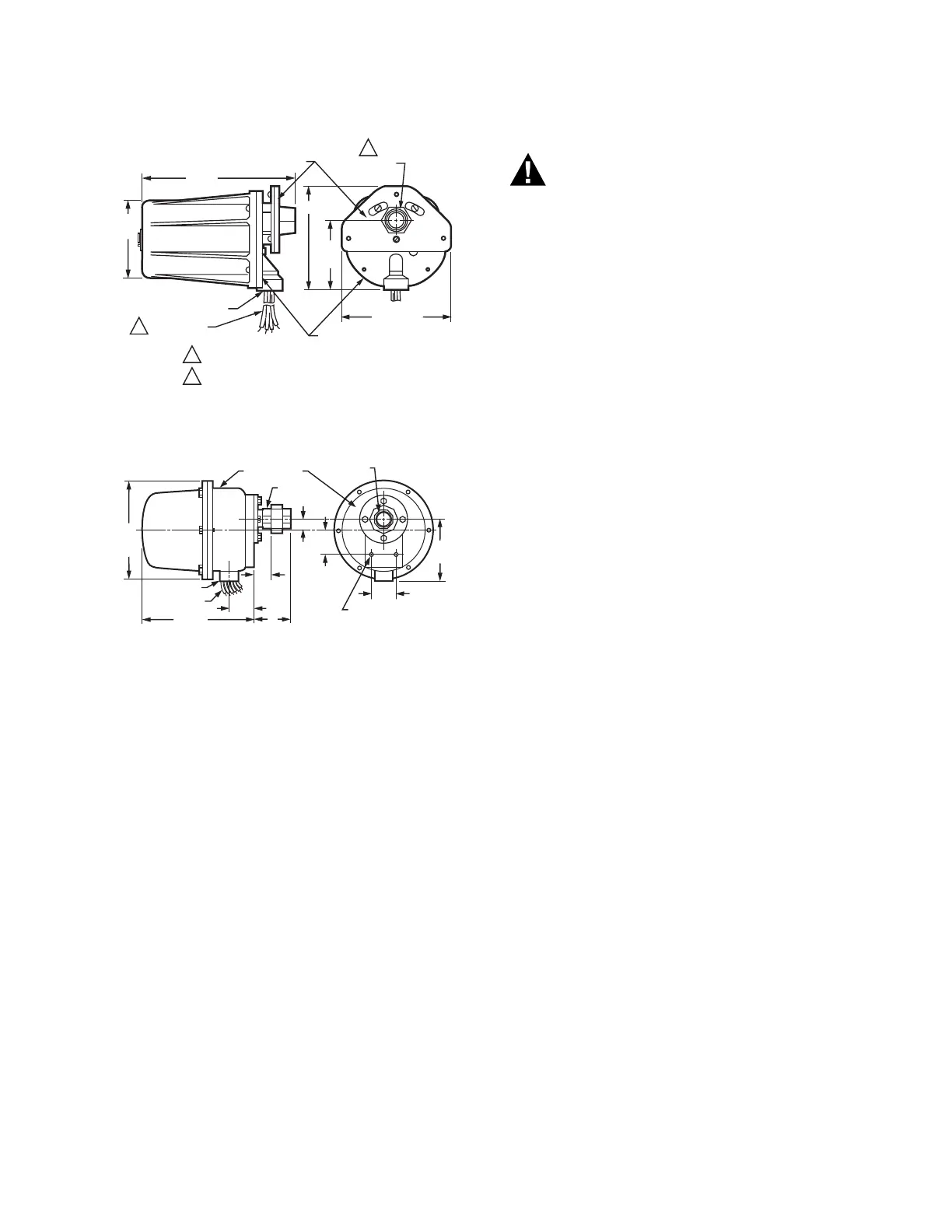

Fig. 1. Dimensions of C7961E in inches. (mm).

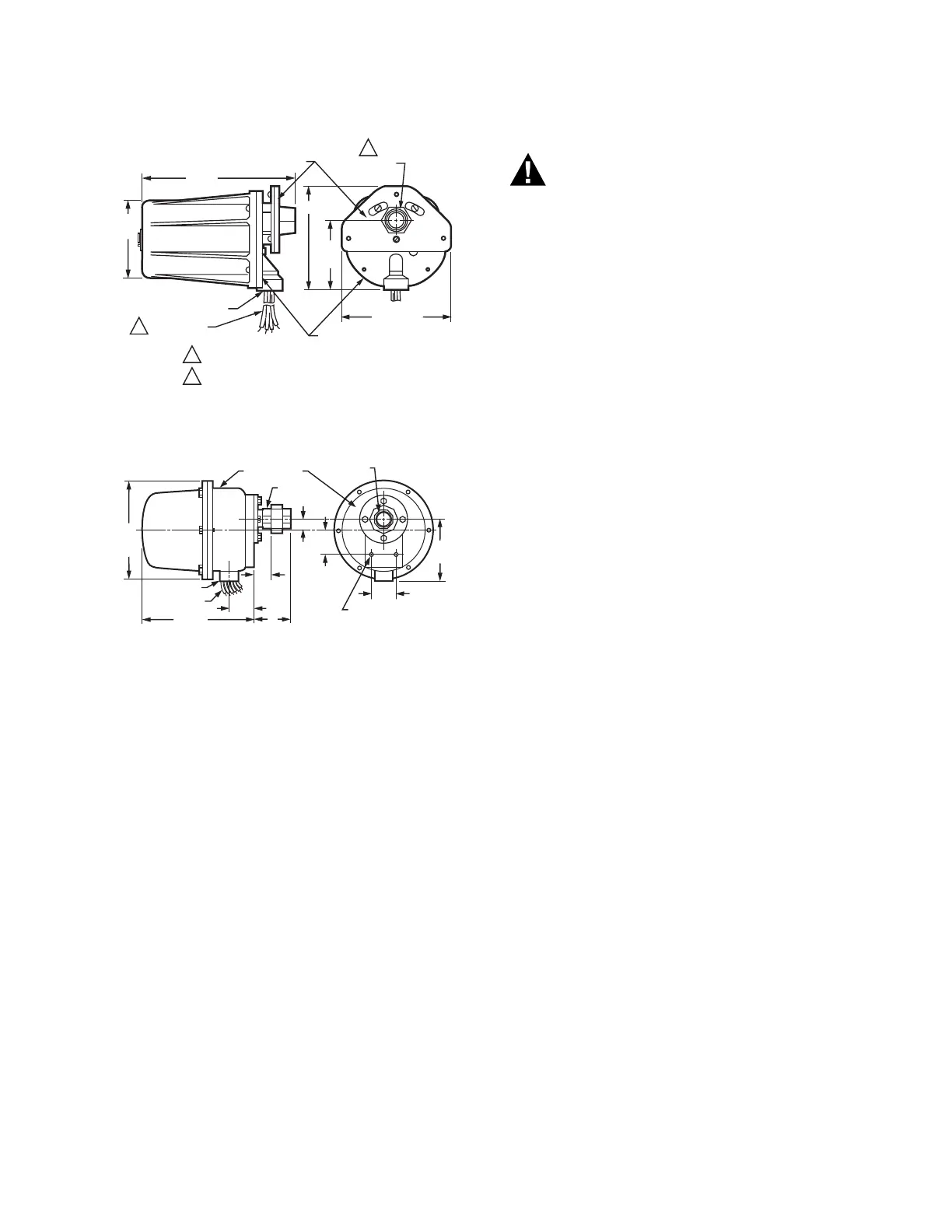

Fig. 2. Dimensions of C7961F in inches. (mm).

Accessories:

C7961E:

118367A Swivel Mount.

123539 Antivibration Mount.

122748 Quartz Viewing Window, rated for 50 psi

(345 kPa).

124204 Quartz Focusing Lens, rated for 20 psi (138 kPa);

increases the detector-sensed ultraviolet radiation.

120934 Mounting Flange, aluminum, with 3/4 inch NPT

internal threads for attaching to sight pipe.

124198 Mounting Flange, aluminum, with 1 inch NPT inter-

nal threads for attaching to sight pipe.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condi-

tion.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced flame safeguard

service technician.

4. After installation is complete, check out product opera-

tion as provided in these instructions.

Electrical shock hazard.

Can cause serious injury or death.

Disconnect power supply before beginning installation

to prevent electrical shock and equipment damage.

More than one disconnect may be involved.

NOTICE: Per industry standards, a conduit seal or a cable

type that is sealed is required to be installed in a device

that can result in flammable gas or flammable liquid flow

through a conduit or cable to an electrical ignition source

in the event of a seal leakage.

IMPORTANT

1. Do not connect these detectors to non-Honeywell

manufactured controls (primaries, programmers, mul-

tiburner systems, and burner management systems).

Unsafe conditions could result.

2. All wiring must be NEC Class 1 (line voltage).

3. Voltage and frequency of the power supply connected

to this detector must agree with the values marked on

the detector.

4. Sight the detector so it does not respond to ignition

spark.

5. On multiburner installations, each detector must

respond only to the flame of the burner it is supervis-

ing.

Proper flame detector installation is the basis of a safe and

reliable flame safeguard installation. Refer also to the burner

manufacturer instructions. Carefully follow all instructions for

the best possible flame detection application.

Basic Requirements

The combustion flames of most carbon-based fuels emit

sufficient ultraviolet radiation to enable the C7961 Solid State

(Purple Peeper) Ultraviolet Flame Detector to prove the

presence of a flame in a combustion chamber. The detector is

mounted outside the combustion chamber with its mounting

flange or union threaded to one end of a sight pipe inserted

through the wall of the combustion chamber. The ultraviolet

sensing tube in the flame detector sights the flame through the

pipe.

When a flame is present, the C7961 senses the ultraviolet

radiation emitted. The C7961 then produces a signal that is

sent to the amplifier in the flame safeguard control. The

amplified signal pulls the flame relay into the control to allow

proper system operation.

Because it is necessary for the C7961 to actually see the

flame, it is best to locate the detector as close to the flame as

physical arrangement, temperature, and other restrictions

permit. These restrictions are described in detail in the

following paragraphs.

Determine Location

Before beginning the actual installation, determine the best

location for mounting the detector. Carefully consider the

factors discussed in this section before deciding on the

location.

MOUNTING FLANGE

1/2–14 NPSM

LEADWIRES

FACEPLATE

3/4–14 NPT

M24000B

3-3/4

(95)

7-7/32

(183)

5-1/8 (130)

3-7/16

(87)

5-1/4 (133)

1

1

2

2

C7961E1014, E1022 1 INCH NPT MODELS

C7961E1022, E1030 CONNECTOR MODELS.

M1963A

FACEPLATE

PIPE

UNION

8

(203)

DIA.

1/2-14 NPT

LEADWIRES

9 (229)

2

(51)

5

(127)

1-11 1/2 NPT

2-1/16

(52)

1-1/2

(38)

5/16-18 UNC-2B BY

7/16 (11) DEEP

MOUNTING HOLES (2)

2 (51)

1 (25)

3

(76)

Loading...

Loading...