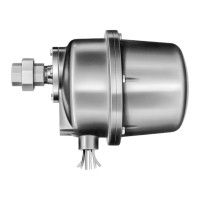

C7961E,F DYNAMIC SELF-CHECK ULTRAVIOLET FLAME DETECTOR

9 65-0267-09

Table 1. Flame Signal.

a

Shutter operation of the C7961 may cause fluctuations in the voltage reading. Read the average stable voltage, disregarding the

peaks.

b

Shutter operates at 3 Hz rate, the 7800 Series conducts an additional shutter test every 5 seconds..

2. Start the burner and run through the Ignition period. Igni-

tion spark should occur, but the flame LED must

not light. The flame signal should not be greater than

0.25 Vdc.

3. If the flame relay does pull in, reposition the detector far-

ther from the spark, or relocate/resight the detector to

eliminate/reduce the detector response to reflected UV

radiation. It may be necessary to construct a barrier to

block the ignition spark from the detector view. Continue

adjustments until the flame signal due to ignition spark is

less than the flame signal values indicated in step 2.

Response to other Ultraviolet

Radiation Sources

Some sources of artificial light produce small amounts of

ultraviolet radiation. Under certain conditions, an ultraviolet

detector responds as if it is sensing a flame. Do not use an

artificial light source to check the response of an ultraviolet

flame detector. To check for proper detector operation, conduct

flame failure response tests under all operating conditions.

Weld the Sight Pipe

When the flame signal is acceptable after all adjustments are

made, remove the detector and weld the sight pipe in its final

position. (If you are using a swivel mount, the pipe may be

already welded.) Then reinstall the detector.

Final Checkout

Before putting the burner into service, check out the installation

using the Checkout procedures in the Instructions for the

appropriate flame safeguard control. After completing the

Checkout, run the burner through at least one complete cycle

to verify correct operation.

IMPORTANT

Do not put the system into operation until all Checkout

tests in the Instructions for the appropriate flame safe-

guard control and any others specified in the burner

installation instructions are satisfactorily completed.

TROUBLESHOOTING

Electrical shock hazard.

Can cause serious injury or death.

Open the master switch to disconnect power before

removing or installing the detector or its cover. More

than one disconnect may be involved.

Equipment Required

A volt-ohm meter with a minimum sensitivity of one

megohm/volt and a zero to five or ten Vdc scale is suggested.

When the Keyboard Display Module is included with the

control, a flame signal displays on the module.

For replacement parts, see Specifications section.

Unsatisfactory Flame Signal

If a satisfactory flame signal (see Table 1) cannot be obtained

while adjusting the sighting position of the detector, follow

these procedures. If you encounter other problems in the

system, refer to the Troubleshooting section in the instructions

for the appropriate flame safeguard control.

NOTE: For instructions to replace the viewing window,

see

the Service section.

Troubleshooting Procedures

First perform the Preliminary Inspection. Then follow the

applicable procedures for either a low meter reading or a zero

meter reading. After reinstalling the detector or replacing its

cover, recheck the meter reading. To try to obtain the proper

flame signal, adjust the position of the detector. If you complete

all of the procedures and yet cannot obtain a proper flame

signal, replace the detector.

Preliminary Inspection

1. Check for the proper line voltage. Make sure the master

switch is closed, connections are correct, and power

supply is of the correct voltage and frequency.

2. Check the detector wiring for defects:

a. Incorrect connections.

b. Wrong type or size of wire.

c. Deteriorated wire.

d. Open circuits.

e. Short circuits.

f. Leakage paths caused by moisture, soot, or dirt.

3. With the burner running, check the temperature at the

detector. If it exceeds 175°F (79°C):

a. Add additional insulation between the wall of the

combustion chamber and the detector.

b. Add a shield or screen to reflect radiated heat away

from the detector, or

c. Add cooling (refer to Sight Pipe Ventilation and

Accessories sections).

Flame Detector

Plug-in Flame

Signal Amplifier Flame Safeguard Control(s)

Minimum

a

Acceptable Steady

Voltag e (Vdc )

Maximum Expected

Voltag e (Vdc )

C7961E,F R7851C Dynamic

Self-Check

a,b

7800 Series or R7140 1.25 5.0

Loading...

Loading...