S9200U1000 UNIVERSAL HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

19 69-2075—01

TROUBLESHOOTING

WARNING

Fire, Explosion, or Electrical Shock Hazard.

Can cause severe injury, property damage, or death.

Do not attempt to modify the physical or electrical

characteristics of this device in any way. Replace

it if troubleshooting indicates a malfunction.

IMPORTANT

1. The status codes outlined in Table 10, Table 11,

and Table 12 beginning on page 19 are a gen-

eral guide. Follow appliance manufacturer ser-

vice instructions when available.

2. Take all meter readings within the Trial for

Ignition period. After the ignition period ends,

before continuing, reset the system by turning

down the thermostat for at least five seconds but

for less than 20 seconds.

3. If any component does not function properly,

make sure it is correctly installed and wired

before replacing it.

4. Static discharge can damage the integrated

furnace control. Touch an appliance metal

surface to discharge static electricity before

touching the furnace control.

5. The S9200U1000 cannot be repaired. If it

malfunctions, replace it.

6. Only trained, experienced service technicians

should service integrated furnace control systems.

Perform the checkout steps listed in “Checkout” on

page 13 before beginning any troubleshooting

procedure. After troubleshooting, check out the

system again to be sure it is operating normally.

LED Indicators

The S9200U1000 has three LEDs. The three LEDs from

left to right as shown in Fig. 4 on page 9 are:

• Flame – Amber LED

The Amber LED Indicates flame status such as weak

or no flame. The Flame status codes are mapped in

Table 10.

• STATUS – Red LED

The Red LED indicates general system status, such as

the presence of a call for heat and various error codes.

The Status LED Status codes are mapped in Table 11

on page 20.

• E-COM – Green LED

This Green LED indicates EnviraCOM™ transmission

is underway. The LED is directly linked to communica-

tion on the EnviraCOM™ bus. The E-COM LED Status

codes are mapped in Table 12 on page 21.

— A typical transmitted message appears as a rapid

flashing of the green LED.

— A typical received message appears as single

blink, indicating the S9200U1000 has acknowl-

edged the message.

NOTE: The E-COM LED is active even if a conventional

thermostat is controlling the appliance.

Flash Code Descriptions

The LEDs will flash codes at various intervals. Each pulse

type indicates a specific functionality/ message type.

• Periodic Blink (Normal): 0.5 second on, 0.5

second off

• Pulse: A 0.25 second flash followed by 3.75

seconds of off time.

• Heartbeat: Constant 0.5 second bright, 0.5

second dim cycles.

• Standard LED Fault Pattern (Single X

Flash): LED flashes X times at 2HZ, then off

for 3 seconds

• Advanced LED Fault Pattern (X + Y Flash):

LED flashes X times at 2Hz, remains off for one

second, flashes Y times at 2Hz, remains off for

three seconds, and then repeats.

Table 10. Flame Status Codes (Amber LED).

Flash Code

a

a

Flash Code Descriptions:

- Pulse: A 0.25 second flash followed by 3.75 seconds of off time.

- Heartbeat: Constant 0.5 second bright 0.5 second dim cycles.

- Periodic Blink: 0.5 second on, 0.5 second off. During local history recall, this fault is flashed as a 1 + 2 pattern.

Amber LED Status Code and Error Description Check / Repair

OFF Control powered- No flame Not Applicable (normal operation)

Heartbeat Control powered- Call for heat - Flame present Not Applicable (normal operation)

Periodic Blink

b

b

During local history recall, this fault is flashed as a 1 + 2 pattern.

Call for heat - Low flame current Check: Flame rod for contamination or loose wiring; low gas

pressure.

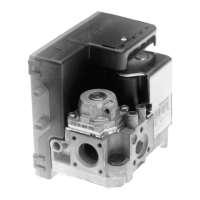

Heartbeat Call for heat - Flame sense out of sequence - Flame still present Check/Repair: Flame at burners, if present replace gas valve.

OFF All other conditions Not Applicable

Loading...

Loading...