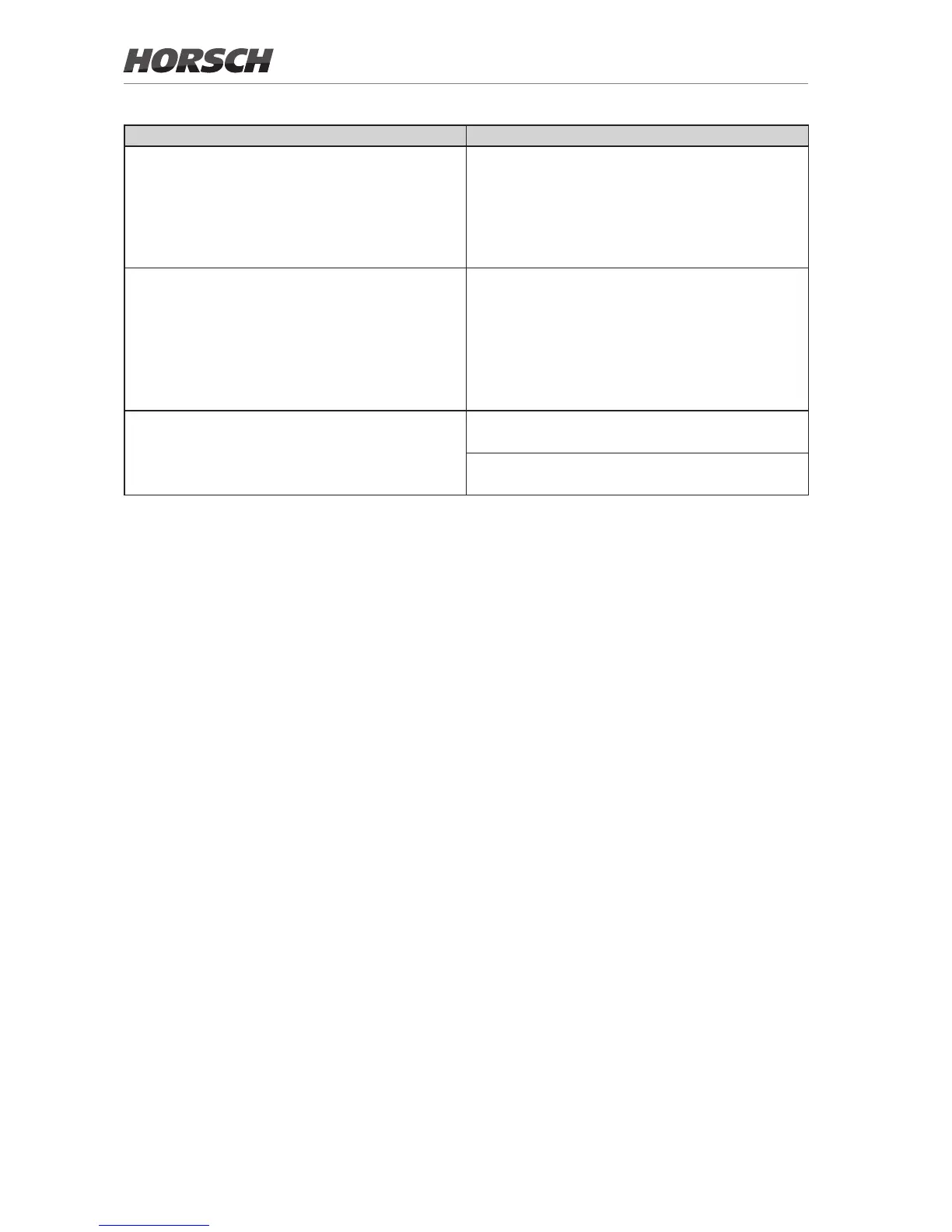

Possible causes Solution options

Sensor failure The system continues working as long as one sensor

still functions.

Check if the use of AutoForce is still practical.

Short-circuit (measured value > 25 mA); the input to the

job computer was disabled.

Turn the machine o and on again. The job computer is

reset if the fault was rectied.

Wiring between sensor and slave computer is defective. Replace the aected component.

Sensor defective. Replace the sensor.

Deactivate the failed sensors in the parameter screen.

Switch to manual mode.

Check the coulter pressure Check the selection of the coulter pressure valve.

Open Diagnostics and check the sensor values.

Switching on the fertiliser and demand fan.

Adjust the % values in diagnostics.

The hydraulic pressure rises when increasing the PWM

signal; observe the pressure gauge on the fertiliser

hopper.

Only values in the range of 25-55 % cause a change of

the hydraulic pressure.

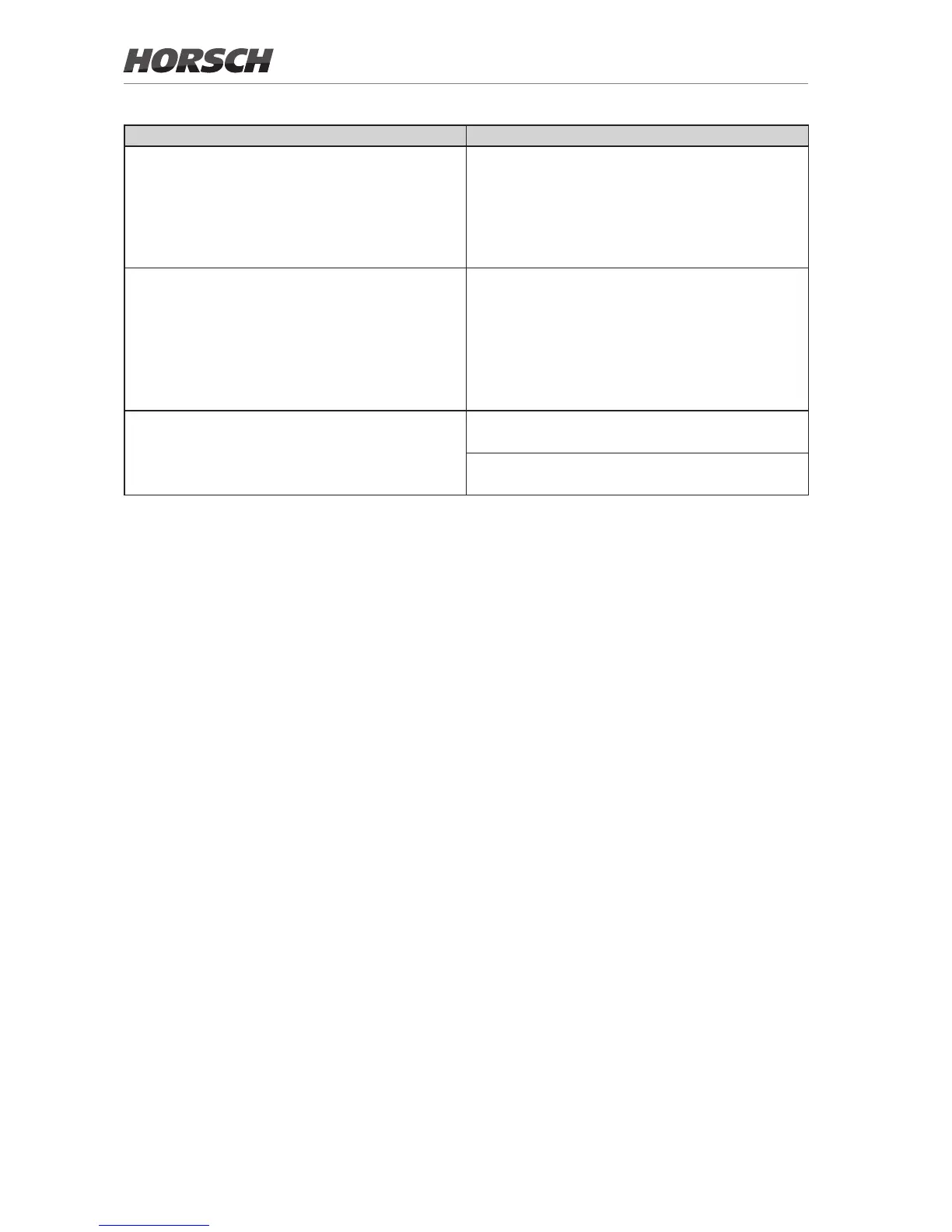

Uneven placement depth Placement depth diers from row to row.

Cam wear diers from row to row. Replace cams.

Sensor calibration values not okay. Teach sensor.

Placement depth in row varies.

Speed too high. Reduce the speed.

Sensor calibration values not okay. Teach sensor.

Loading...

Loading...