Repair Tips

25

Go to cover page

HP L2025

7

HP L2025

HP L2025

27

0. Warning

All ICsand many other semi-conductors are susceptible to

electrostaticdischarges (ESD). Careless handling during

repair can reduce life drastically. When repairing, makesure

that you are connectedwith thesamepotential as the mass

of the un

itvia a wristwrap with resistance.Keep components

and toolsalso atthesamepotential!

1. Servicing of SMDs (Surface MountedDevices)

1.1 Generalcautions on handling and storage

-Oxidation on the terminals of SMDs resultsin poorsoldering.

Do not handle SMDs with bare hands.

-Avoidusing storageplaces that are sensitive to oxidation

such as places with sulphur or chlorine gas,direct sunl

ight,

high temperatures orahigh degree of humidity. The

capacitance or resistance value of the SMDs maybe

affectedbythis.

- Rough handling of circuitboards containing SMDs may

cause damage to the componentsas

well as the circuit

boards.Circuitboards containing SMDsshould never be

bent or flexed. Different circuitboardmaterialsexpand and

contract atdifferent rates whenheatedor cooled and the

componentsand/orsolder conn

ections maybe damaged

due to thestress.Never rub orscrape chip componentsas

this maycause the value of the component to change.

Similarly, do not slide the circuitboard across any surface.

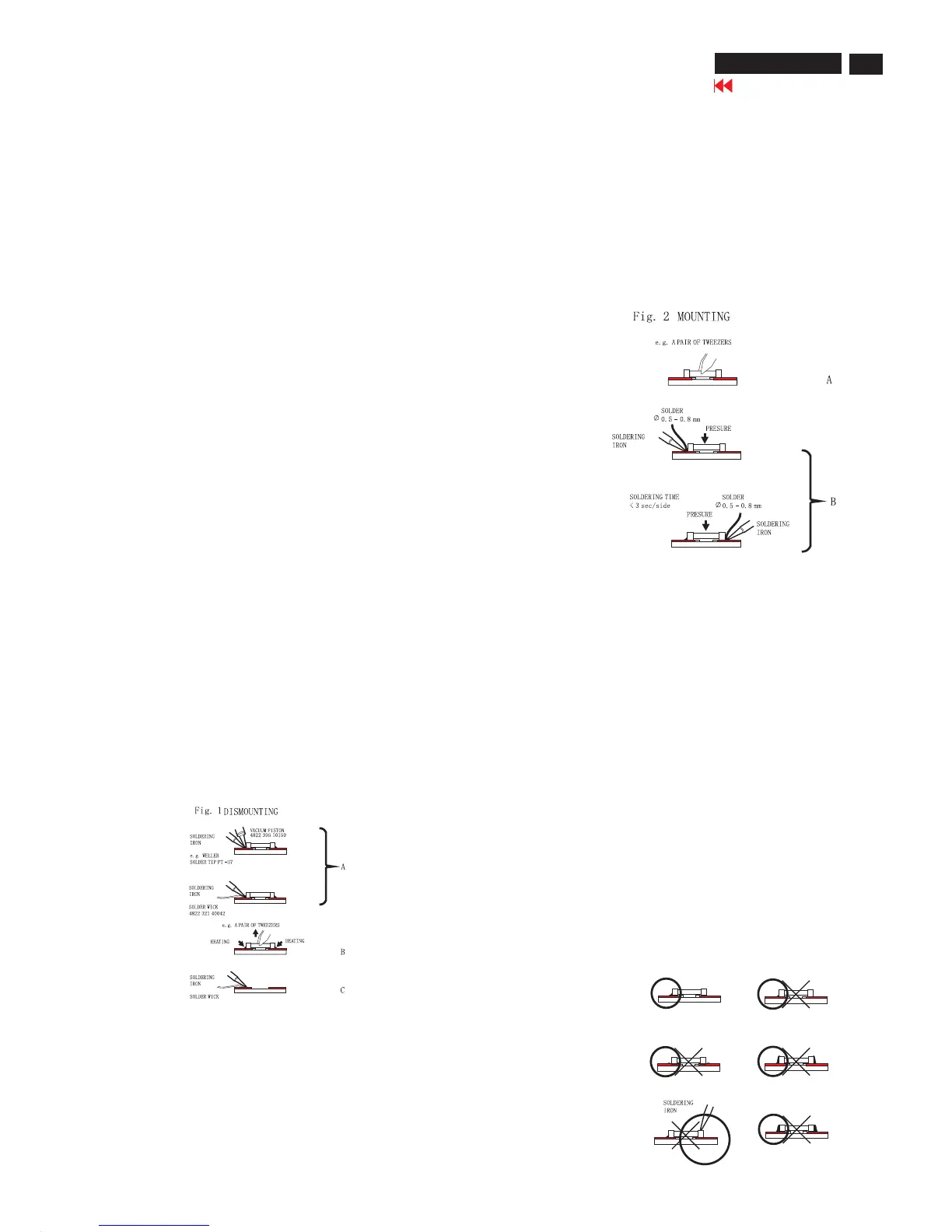

1.2 RemovalofSMDs

-Heatthesolder (for 2-3 seconds) at each terminalofthe

chip.Bymeans of litz wire and aslight horizontalforce,

small components canberemovedwith thesoldering iron.

Theycan alsoberemovedwith asolder sucker (see Fig.

1A)

While holding the SMD with a pair of tweezers,takeitoffgently using the

soldering iron's heat appliedtoeach terminal(see Fig. 1 B).

- Remove theexcess solder on thesolder lands by means of

litz wire orasolder sucker (see Fig. 1C).

1.3 Caution on removal

-Whenhandling thesoldering.iron. use suitable pressure and be careful.

-When removing the chip, do not use undue force with the pair of tweezers.

- Thesoldering iron to be used(approx. 30 W) should

preferably beequippedwith a thermal control (soldering

temperature: 225 to 250 C).

- The chip, onceremoved, mustnever bereused.

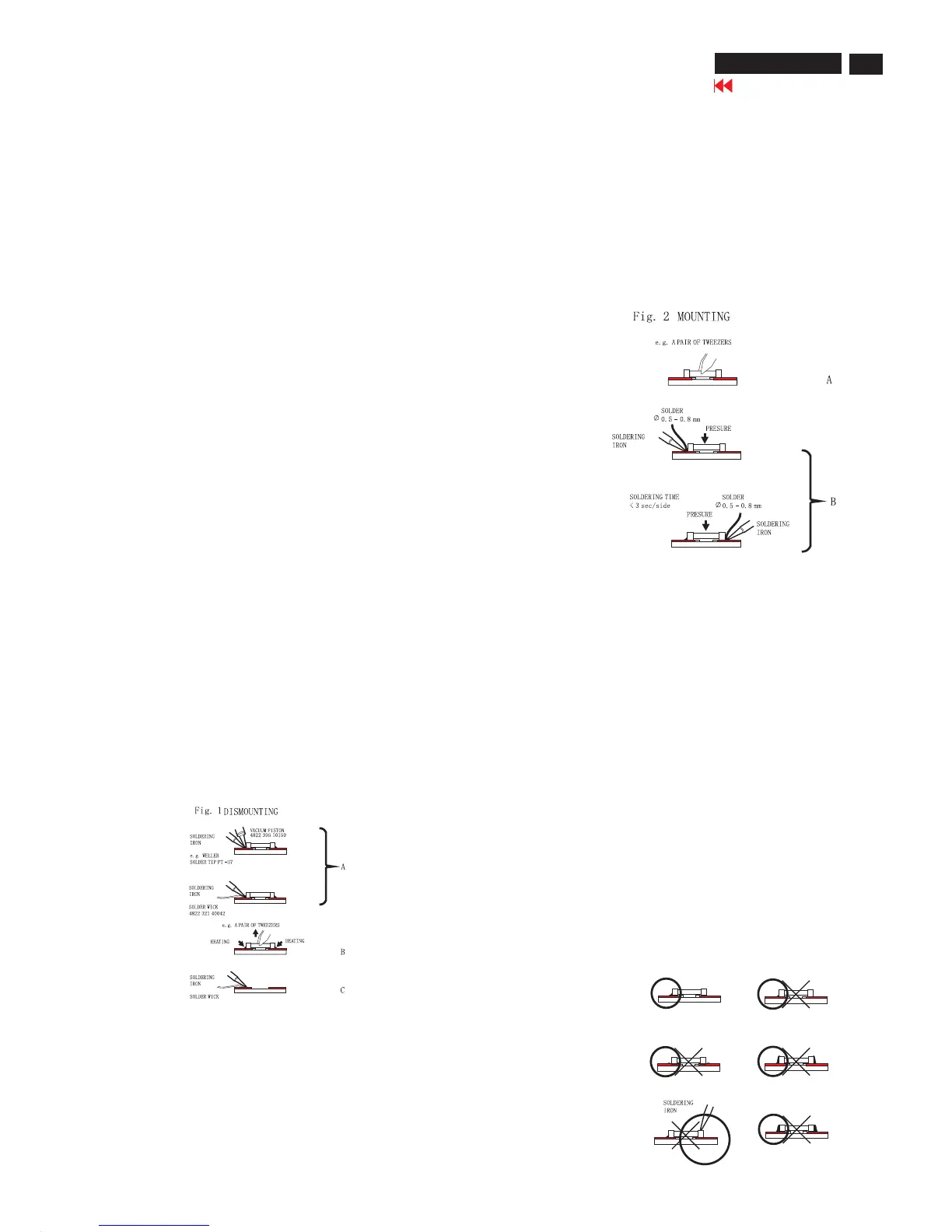

1.4 Attachment of SMDs

- Locate the SMD on thesolder lands by means of tweezers

and solder the component on oneside.Ensure thatthe

component is positionedcorrectly on thesolder lands (see Fig.2A).

-Next complete thesoldering of the terminals of the

component (

see Fiq. 2B).

2. Caution when attaching SMDs

-When soldering the SMD terminals, do not touch them

directly with thesoldering iron. Thesoldering should be

doneasquickly as possible,care mustbe takentoavoid

damage to the terminals of the SMDs themselves.

-Keep the SMD's body in conta

ct with the printedboardwhen

soldering.

- Thesoldering iron to be used(approx. 30 W ) should

preferably beequippedwith a thermal control (soldering

temperature: 225 to 250 C).

- Soldering should not be done outside thesolder land.

- Soldering flux (of rosin) maybe used, but should not be

acidi

c.

- After soldering, letthe SMD cool down gradually at room

temperature.

- The quantity of solder mustbeproportionaltothesize of the

solder land. If the quantity is too great, the SMD might

crack or thesolder lands might be torn loose from the

print

edboard(see Fig. 3).

Fig.3 Examples

Right

HP L1940

Loading...

Loading...