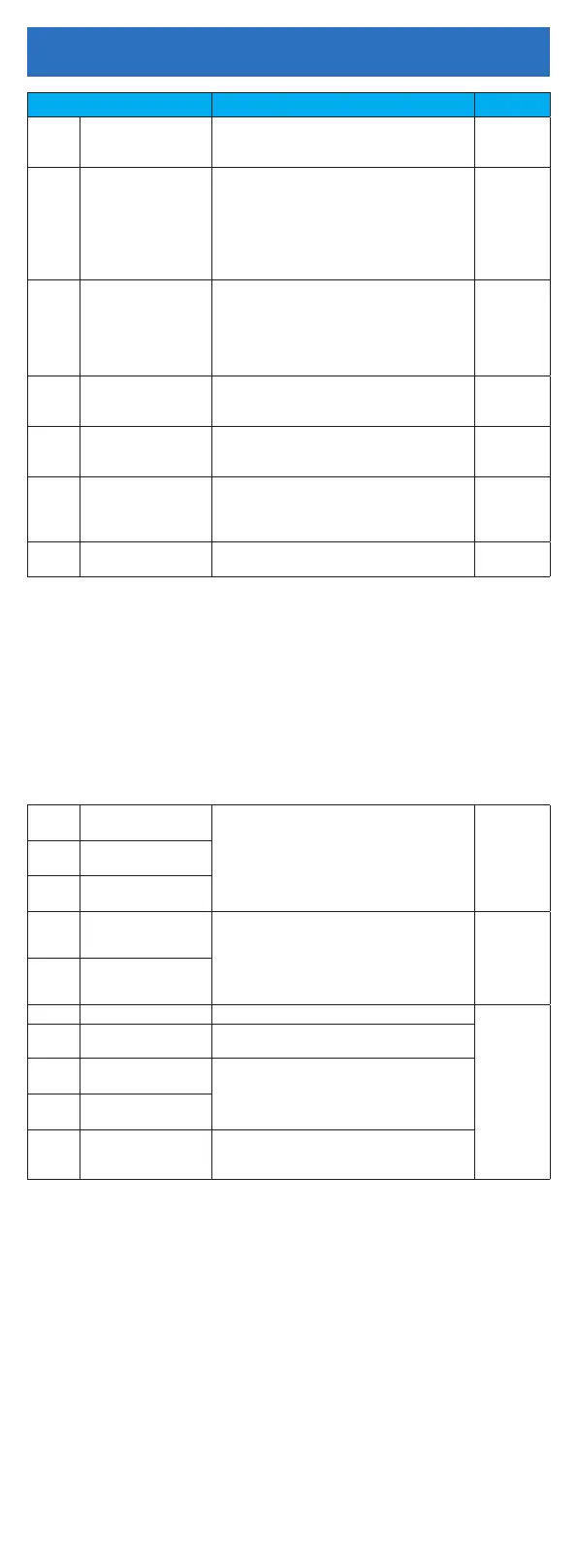

Fault Countermeasure Remark

E0018

Inverter output

ooad

• Check load and mechanical

transmission

• Set proper F20.03 - F20.05

HD09/

HD09-S

none

E0019 Motor overload

• Adjust proper F09.00 - F09.06 (V/f

curve)

• Check the input power

• Long-term low-speed and large-load

operation, replace the inverter motor

• Check load and mechanical

transmission

E0020 Motor overheat

• Reduce load; Repair and replace

motors

• Increase F03.01 - F03.08 (Acc. and

Dec. time)

• Correctly set F08.00 - F08.04/

F13.01 - F13.05 (motor parameters)

HD09/

HD09-S/

HD20 none

E0021

Control board

EEPROM read and

write fault

• Contact the supplier for repairing

E0022

Keypad EEPROM

read and write

fault

• Replace the keypad

• Contact the supplier for repairing

E0023

Parameter setting

fault

• Select a motor that matches the

inverter power

• Correctly set F08.00 - F08.04/

F13.01 - F13.05 (motor parameters)

E0024

External device

fault

• Check external device

E0025 PID reference loss

• Check wiring

• Seek technical support

HD07-S

HD09/

HD09-S

none

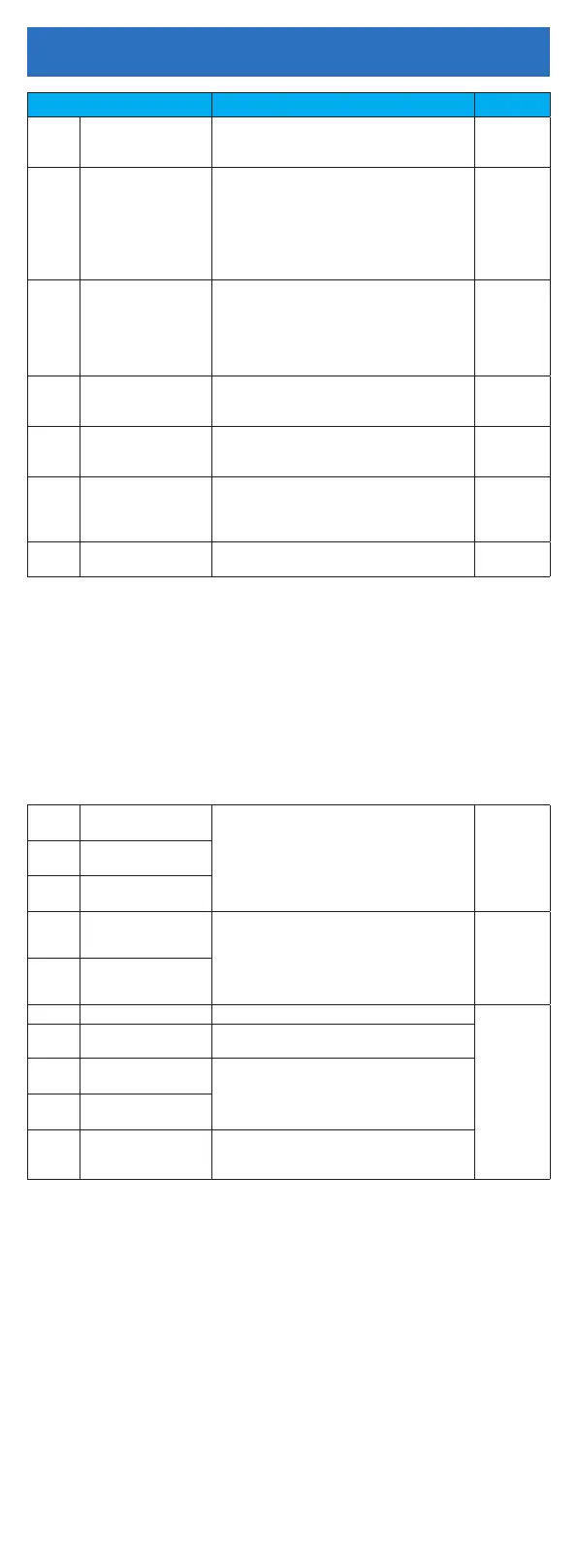

E0026 PID feedback loss

E0027

PID feedback

overrun

E0028

SCI communication

timeout

• Check wiring

• Correctly set F17.00/F17.01

(communication format/baud rate)

• Send data according to Modbus

protocol content

E0029

SCI communication

error

E0030 Encoder reverse • Check the encoder and motor wiring

Only HD50

have

E0031

Encoder

disconnected

• Check the encoder

• Check the encoder wiring

E0032 Motor over speed

• Check motor and load

E0033

Motor speed out of

tolerance

E0034

Tension control

system fracture of

material

• Check wiring

• Check the encoder

Note: E0022 does not aect the normal running of the inverter.

Troubleshooting

Loading...

Loading...