22

LP- 428 REV. 9.2.14

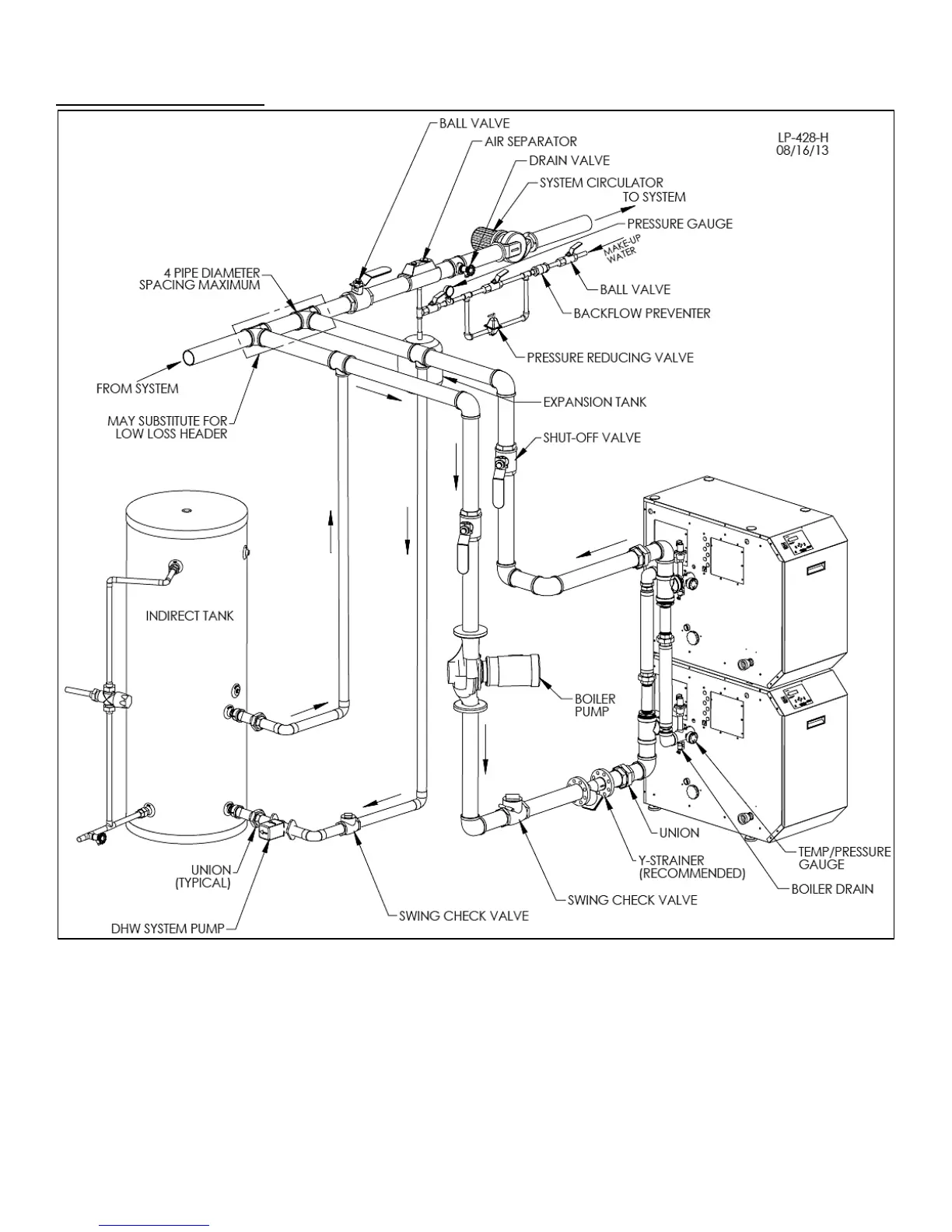

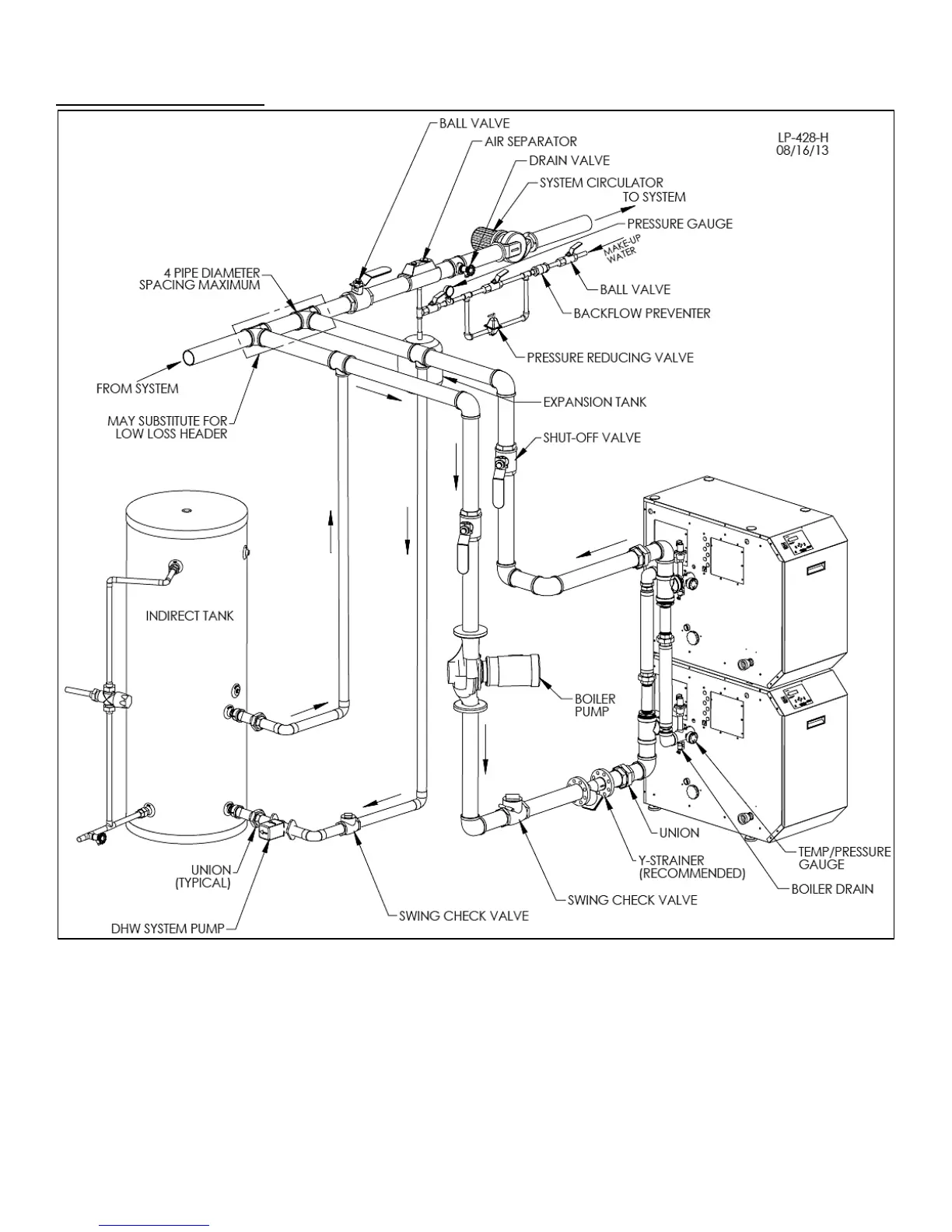

M. BOILER PIPING DETAILS

Figure 7 – Single Boiler Space Heating – Indirect Priority

FIGURE NOTES:

1. This drawing is meant to demonstrate system piping concept only.

2. A mixing valve is recommended if the DHW temperature is set above the factory setting of 119

o

F.

3. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

4. Install a minimum of 6 diameters of straight pipe up and downstream of all closely spaced tees.

5. Piping shown is Primary/Secondary.

6. The minimum pipe size for connecting an HTP indirect fired water heater is 1”.

7. The minimum pipe size for connecting a Mod Con boiler is 3” for both the 1000 and 1700 models.

8. System flow (Secondary Loop) must be greater than the boiler’s Primary Loop flow.

9. Installations must comply with all local codes.

10. In Massachusetts, a vacuum relief valve must be installed on the cold water line per 248 CMR.

Loading...

Loading...