37

LP- 428 REV. 9.2.14

Under no circumstances should the mechanical room ever be under negative pressure. Particular care should be taken where exhaust

fans, attic fans, clothes dryers, compressors, air handling units, etc., may take away air from the unit. Failure to follow these instructions

could result in property damage or personal injury.

Combustion air supply must be completely free of any flammable vapors that may ignite, or chemical fumes which may be corrosive to

the boiler. See Table 1 for a list of combustion air contaminants. These chemicals, when burned, form acids which quickly attack the

stainless steel heat exchanger, headers, flue connectors, and the vent system. The result is improper combustion and premature boiler

failure. Such failure IS NOT covered under warranty.

EXHAUST FANS: Any fan or appliance which exhausts air from the mechanical room may deplete the combustion air supply and/or

cause a downdraft in the venting system. Spillage of flue products from the venting system into an occupied living space can cause a

very hazardous condition that must be corrected immediately.

MINIMUM RECOMMENDED COMBUSTION AIR SUPPLY TO MECHANICAL ROOM

*Outside Air from 2 Openings

Directly from Outdoors

1

*Outside Air from 2 Ducts

Delivered from Outdoors

1

Inside Air from 2 Ducts Delivered from Interior

Space

2

*Outside Air

from 1

Opening

Directly from

Outdoors, in

2

1

Table 9 – Indoor Combustion Air Sizing

The above requirements are for the boiler only; additional gas fired appliances in the mechanical room will require an increase in the net free area and/or

volume to supply adequate combustion air for all appliances.

No combustion air openings are needed when the boiler is installed in a space with

a volume NO LESS than 50 cubic feet per 1,000 BTU/hr of all installed gas fired

appliances. Buildings MUST NOT be of *”Tight Construction”.

1

Outside air openings shall communicate with the outdoors.

2

Combined interior space must be 50 cubic feet per 1,000 BTU/hr input. Buildings

MUST NOT be of *”Tight Construction”.

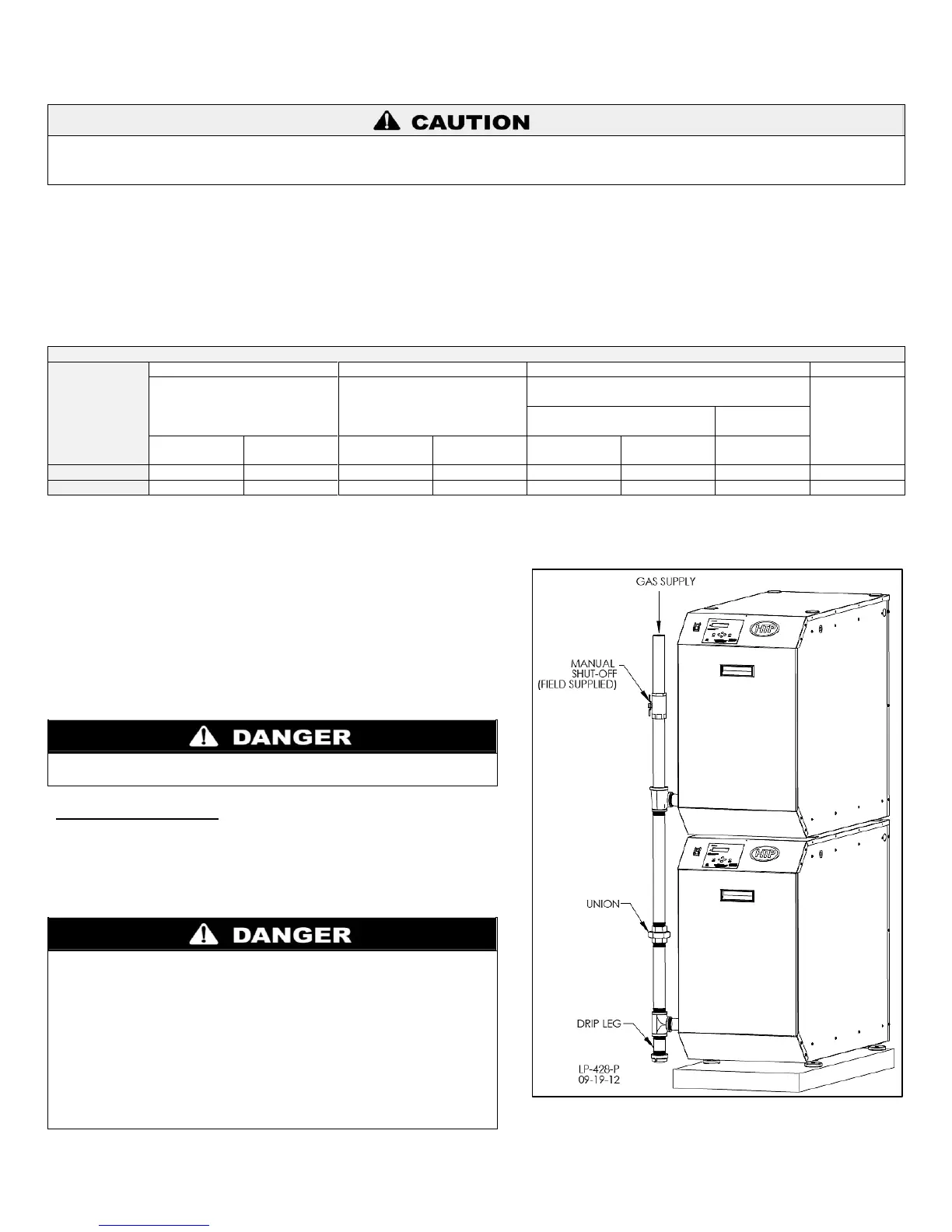

PART 6 – GAS PIPING

A. GAS CONNECTION

The gas supply shall have a maximum inlet pressure of less than 14" w.c.

(3.5 kPa), and a minimum of 3.5" w.c. (.87 kPa). The entire piping system,

gas meter and regulator must be sized properly to prevent pressure drop

greater than 0.5" (.12 kPa) as stated in the National Fuel Gas Code. This

information is listed on the rating label.

FAILURE TO FOLLOW ALL PRECAUTIONS IN THIS SECTION

COULD RESULT IN FIRE, EXPLOSION, OR DEATH!

It is very important that you are connected to the type of gas noted on

the rating plate. “LP” for liquefied petroleum, propane gas, or “NAT”

for natural or city gas. Prior to turning the gas on, all gas connections

must be approved by the local gas supplier or utility, in addition to the

governing authority.

A gas conversion kit comes with Mod Con 1000 boilers ONLY. Field

conversions ARE NOT ALLOWED on the Mod Con 1700. A properly

calibrated combustion analyzer must be used to verify proper

combustion. Failure to follow all above information could result in

property damage, serious injury, or death.

Figure 21 – Gas Connection Detail

Loading...

Loading...