22

LP-505 REV. 4.29.14

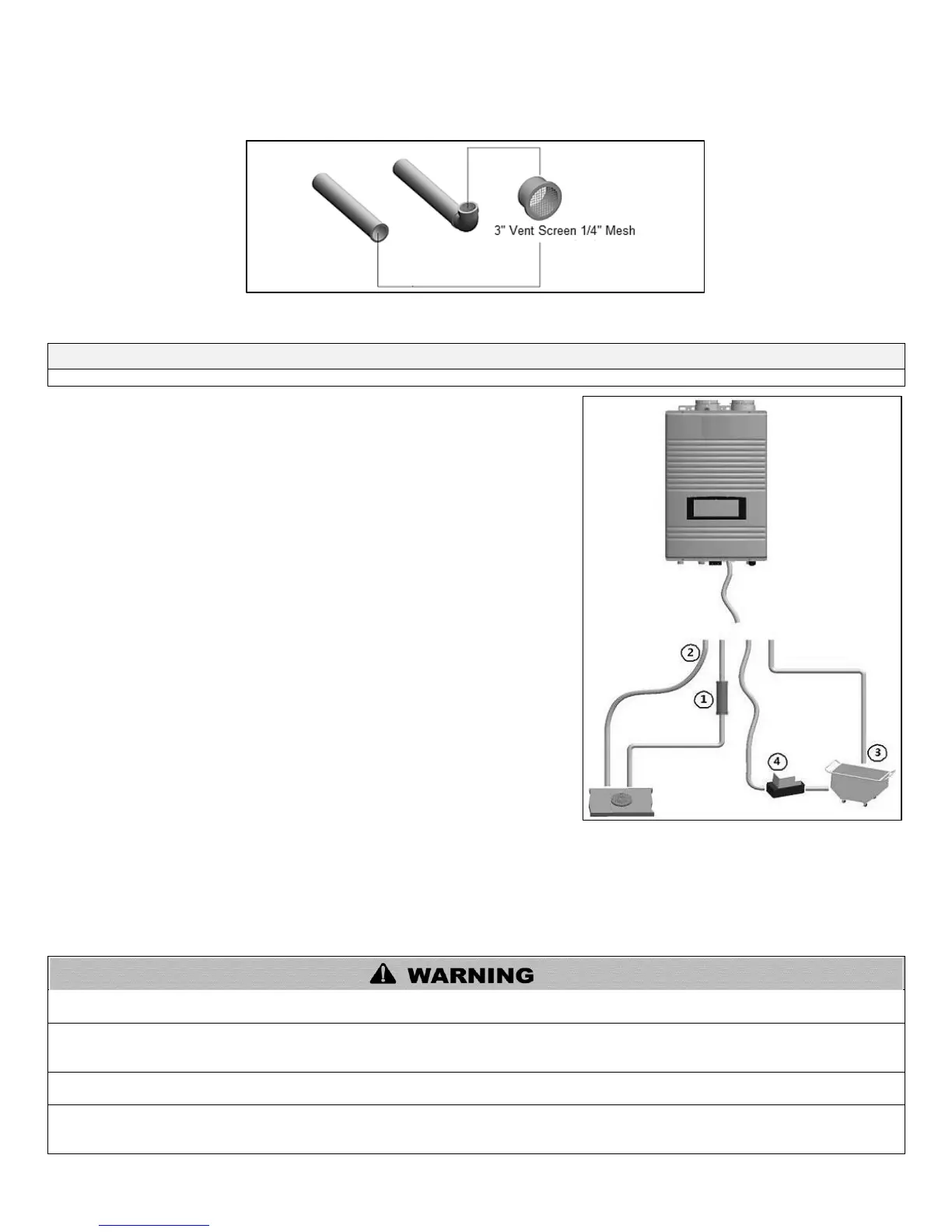

4. Screen Installation

After connecting the intake air and exhaust vent pipes, it is required to install the included screens into the exhaust vent and intake pipe

terminations to prevent damages to the unit due to blockages. See Figure 11 for installation detail.

Figure 11 – Screen Installation - NOTE: Vent termination elbow is meant to be installed open end facing the ground.

Orientation in Figure 11 is meant to demonstrate proper Vent Screen installation ONLY.

Do not connect any other appliance vents to the water heater exhaust vent or intake pipes.

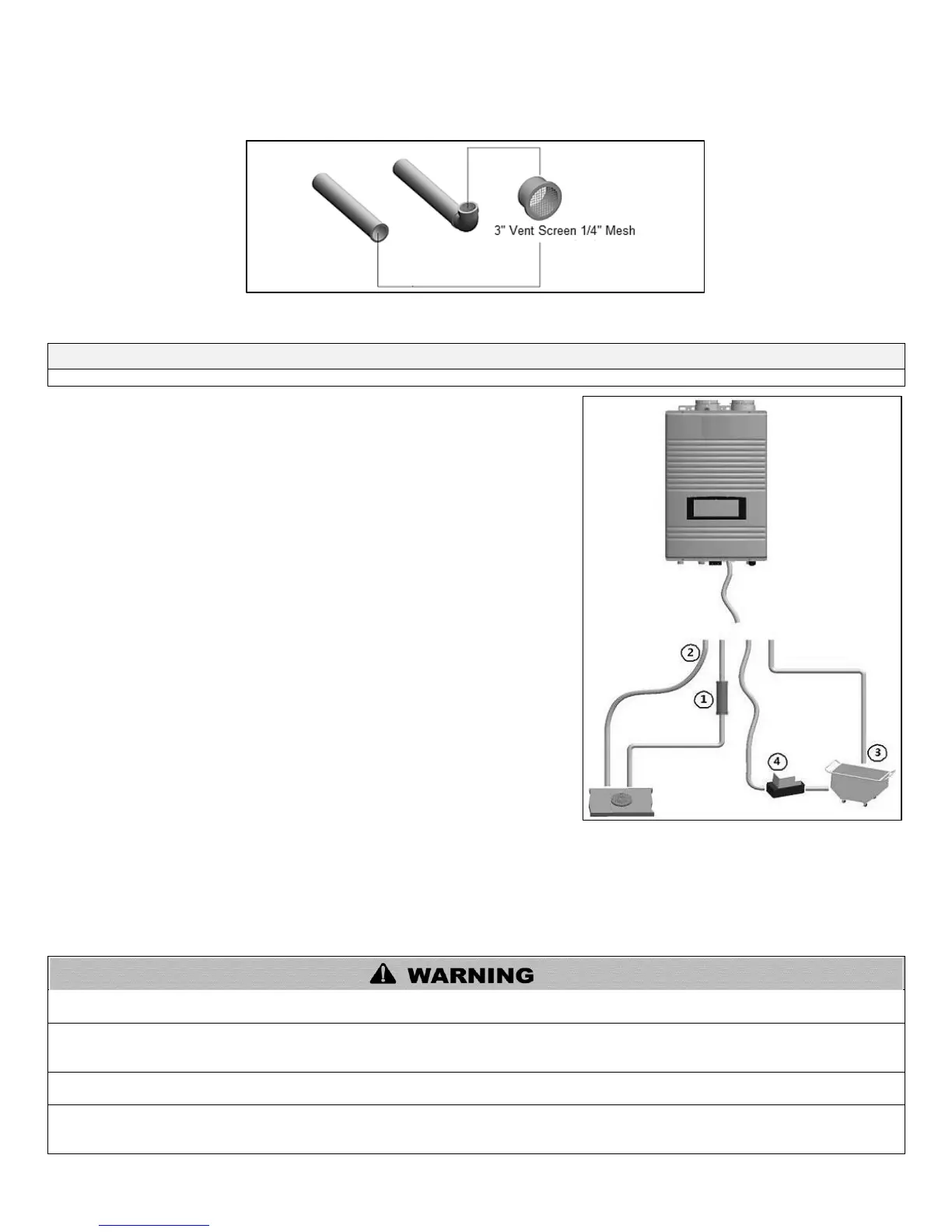

PART 6 – INSTALL THE CONDENSATE DRAIN

1. Due to its efficient design, the water heater produces condensate (water) as a

normal by-product. This condensate is acidic, with a pH level between 3 and 4.

This condensate must be drained away from the water heater and disposed in

accordance with all local regulations.

2. Use corrosion-resistant materials to drain condensate. Use the included flexible

plastic hose or ½” PVC and CPVC drain pipe complying with ASTM D1785, F441,

or D2665 may be used. Cement and primer must comply with ASTM D2564 or

F493. For Canadian applications, use CSA or ULC certified PVC or CPVC pipe,

fittings, and cement.

3. Local building codes may require an in-line neutralizer (1) to be installed (not

included) to treat the condensate. Follow all the installation instructions included

with the neutralizer. If a neutralizer is installed, periodic replacement of the

limestone (or neutralizing agent) will be required. The rate of depletion of the

limestone varies with usage of the water heater. During the first year of water

heater operation, check the neutralizer every few months for depletion.

4. Route the drain line to a nearby floor drain (2), laundry tub (3), or condensate

pump (4).

NOTE: If a nearby laundry tub is used as a disposal for waste water from the

washing machine, draining the condensate into this tub allows the soapy water

discharge to neutralize the acidic condensate.

5. An error will appear on the water heater display if condensate line is blocked. The water heater will not operate with a blocked

condensate line. It is extremely important to have this condition repaired by a qualified service technician.

PART 7 – GAS PIPING

FIRE AND/OR EXPLOSION HAZARD

To avoid serious injury or death, the gas line installation and the gas line inlet pressure test must be done by a licensed professional.

Always match the water heater with the type of gas supplied to the unit (natural gas or LP gas). This water heater must be converted

into propane operation unless specifically manufactured for use with propane. Follow Gas Conversion Manual instructions (separate

document). Propane ready water heaters have the suffix “LP” after the model serial number.

Make sure the gas line pressures are within normal limits. Pressures outside normal limits can result in poor performance and

hazardous operating conditions.

This water heater must be converted into propane operation unless it is specifically manufactured to operate on propane. Propane-

ready water heaters have the suffix “LP” after the model serial number. Failure to ensure the water heater is set to operate on the

provided gas supply could result in property damage, personal injury, or death.

Figure 12 – Condensate Detail

Loading...

Loading...