41

1

Checking Installation Effectiveness

Checking the Installation

2

Checking Equipment Prior to Powering Up

No. Item to Check Method

1 The cabinet is installed in the position specified in the engineering design

documents.

Check the

position.

2 Mechanical parts of the cabinet have been installed correctly and securely, and are

undamaged. Cabinet surfaces are clean and have no scratches.

Check

3 Cable holes at the top and bottom of the cabinet are sealed properly. Check

4 Cables have been run according to specifications in the engineering design

documents.

Check

5 Cables are not damaged or broken and have not been spliced together. Cable

connectors are fastened correctly and securely.

Check

6 Labels at both ends of the cables and fibers have been filled in correctly and are

legible.

Check

7 Fibers outside the cabinet are not squeezed or pressed together by other cables or

articles, and are run through protective corrugated pipe or cable tough.

Check

8 No fibers are bent at a radius of less than 40 mm. No protruding objects obstruct the

paths of the fibers.

Check

9 Fibers are properly arranged and bound with binding straps, and have not been

scratched.

Check

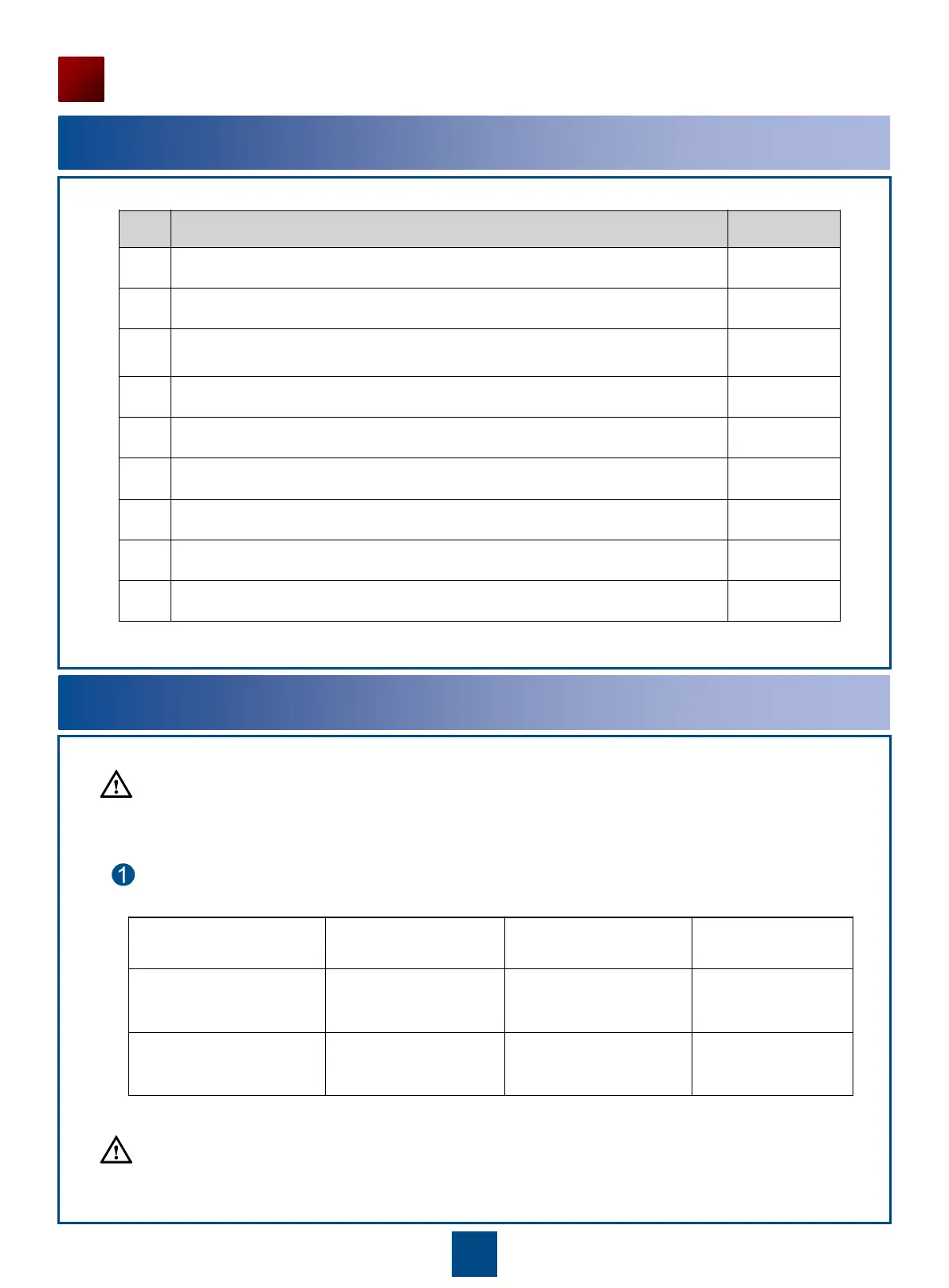

Ensure that fixed optical attenuators have been installed as required before powering on the subrack.

Turn off the power supply facilities, and use a multimeter to measure the resistance between NEG (-),

RTN (+), and PGND.

Turn off all the power switches after the measurement.

Circuit Breaker Resistance Between

NEG (-) and RTN (+)

Resistance Between

NEG (-) and PGND

Resistance Between

RTN (+) and PGND

Turn all the power

switches on the DC power

distribution box to "OFF".

∞ ∞ 0

Turn all the power

switches on the DC power

distribution box to "ON".

> 20,000 ohms > 20,000 ohms 0

CAUTION

CAUTION

Loading...

Loading...