unter 50cc • AC Electric S

stems

.

it run warm. Continuous load should be restricted to 70

m

xim

m l

.

Stoppin

enerator

1

witch o

all electrical devices

consumers

. I

th

eneratin

set has been runnin

under

ull load

or a

lon

er period, do not shut it down abruptl

. Reduce the

lectrical load to about 30

o

the rated load and let it run

or approx. 5 minutes

2 Press the

T

P button

lose the inlet sea water cock

4

witch to an other A

power source, i

available. I

a

ass

stemswitc

is installed, this is done automati-

all

.

.3.6 The Air Conditionin

S

stem

Option

ere are t

ree a

r con

t

on

n

un

ts

nsta

e

on

our

boat. Ensure that

ou read the instructions on the air

onditioner’s owner’s manual

or more detail operatin

inf

rm

ti

n.

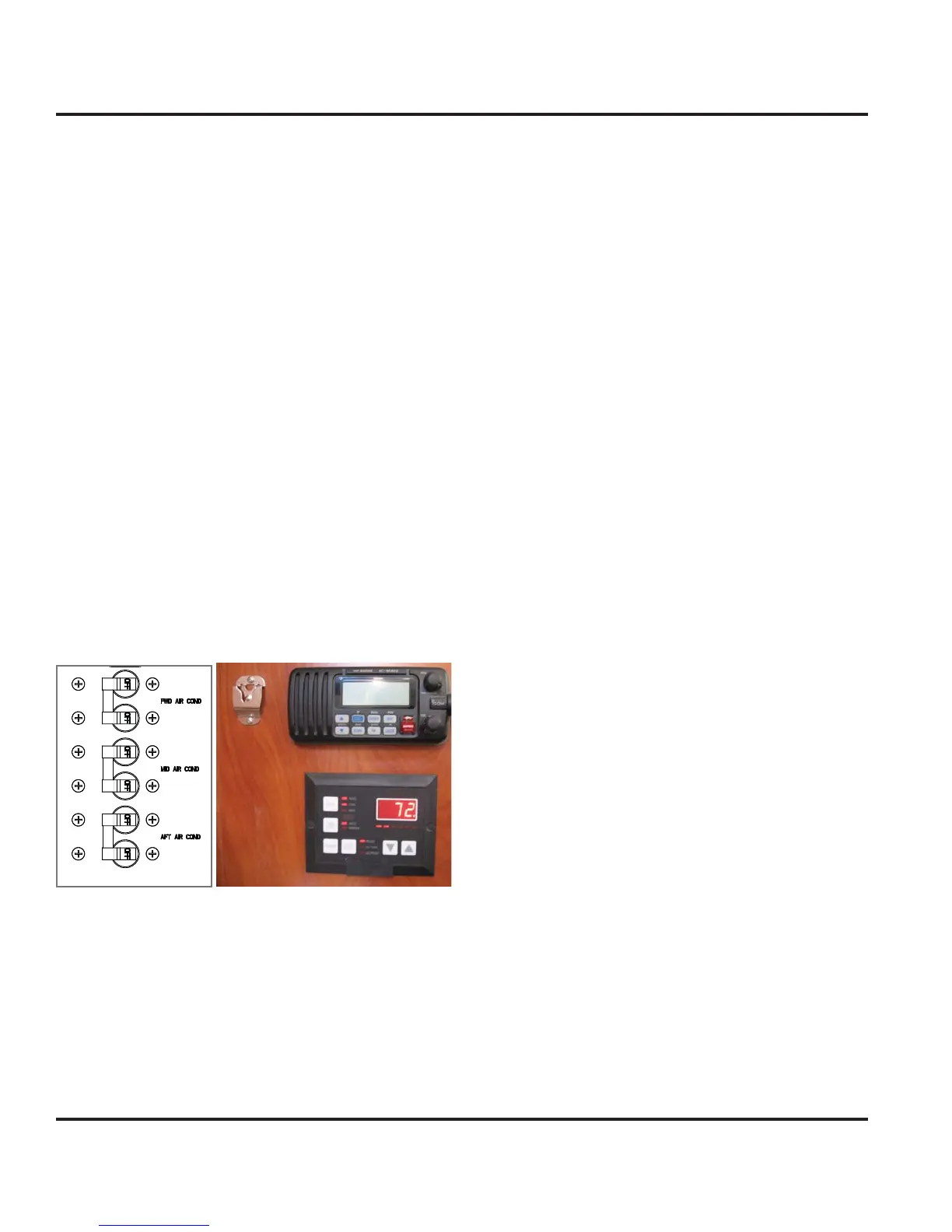

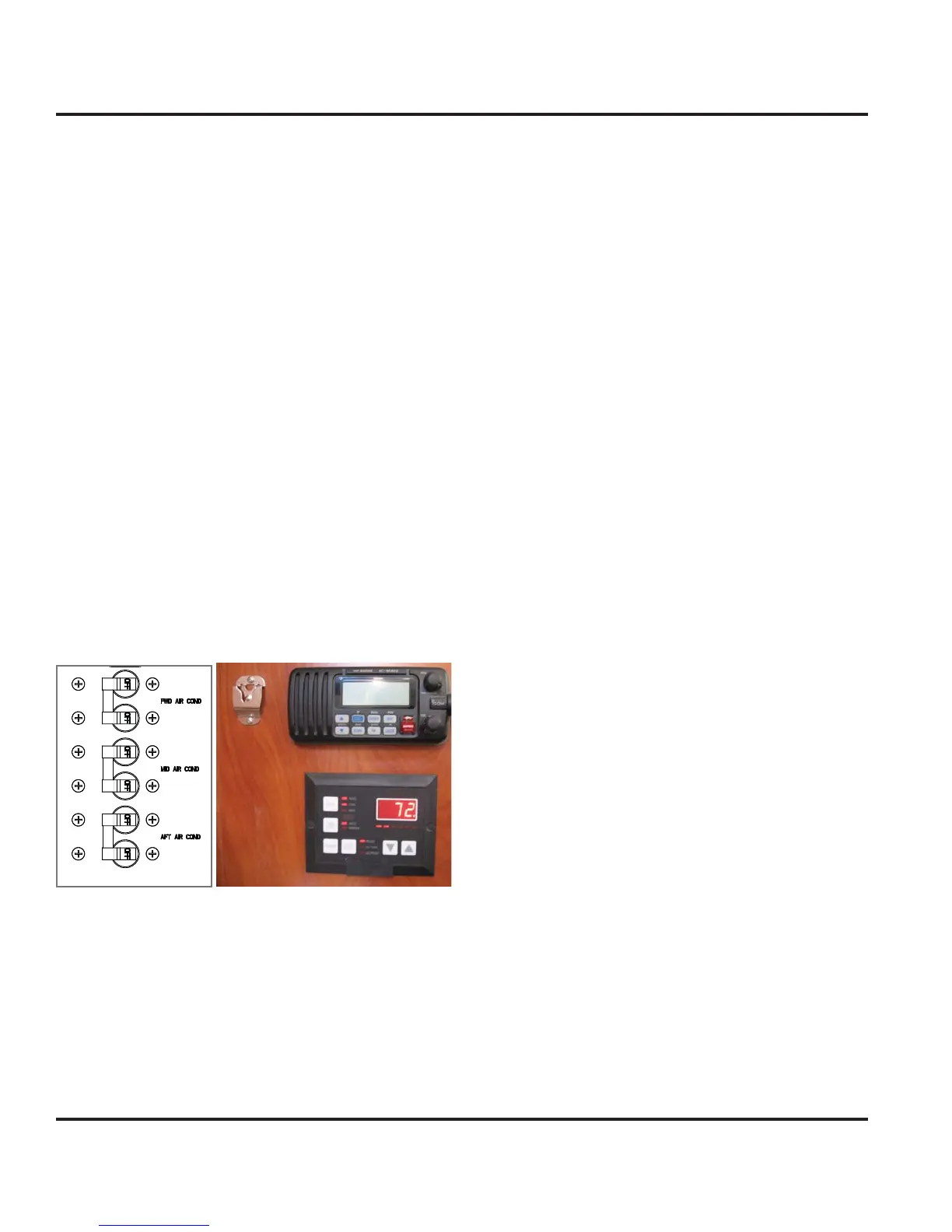

ig. 8.6 Air contioner breakers on AC control panel. the

r cond

t

oner control panel on ma

n cab

n nav

gat

on

tati

n

1. Ensure

ou have 240 volt

230 overseas

power to the

2.

heck to make sure that the seawater intakes, and

dischar

e for the A/C s

stem coolin

is open and that the

tr

in

r i

l

n

n

ri

r

. Ener

ize the Air Conditionin

s

stem at the MDP

ane

.

4.

heck to make sure that the dischar

e is

lowin

at the

Air Conditionin

coolin

water dischar

e.

General O

eration

The A

unit reverse c

cle air conditioner has both a

heatin

and coolin

mode of operation. It uses R-22

r R407c re

ri

erant in a conventional vapor compres-

sion c

cle to trans

er heat

rom the air in the boat to the

water.

n t

e coo

n

mo

e, a

ower

ows t

e ca

n a

r

throu

h the indoor or evaporator coil where it is cooled

and dehumidi

ied. Liquid re

ri

erant passin

throu

h the

vaporator is boiled into a

as b

heat removed from the

air. The warmed re

ri

erant

as enters the compressor

where its temperature and pressure are increased. The

hot refri

erant

as travels to the water coil or condenser

where it is cooled b

the water and condenses to a liquid

Liquid refri

erant is metered back into the evaporator coil

to repeat the process.

n the heatin

mod

the process is reversed. A spe-

ial reversin

valve reverses the flow of the refri

erant

throu

hout the s

stem exchan

in

the roles o

the con-

denser and evaporator. The re

ri

erant

lows throu

h the

water or evaporator coil, picks up heat from the water,

and becomes a vapor. The vapor then enters the com-

pressor w

ere

t

s compresse

to a

er temperature.

It is then pumped to the indoor coil where the air movin

across t

e co

c

s

t

e

eat an

t

e warm a

r

s

blown into the room. The compressed re

ri

erant vapor

ondenses to a liquid as it

ives up heat. Finall

, liquid

refri

erant flows into the capillar

tubes into the indoor

oil where the c

cle is repeated.

e reverse c

c

e a

r con

t

oner

s contro

e

a con-

troller mounted on the main cabin navi

ation station,

port side a

t en

ine bulkhead in a

t cabin and above port

han

in

locker in the forward cabin

l

r

r

t

ir

n

iti

n

r’

wn

r’

m

n

l

r

detail information re

ardin

operatin

of the A/C unit and

m

int

n

n

in

rm

ti

n.

Loading...

Loading...