3.4

Drive Wheel Adjustment

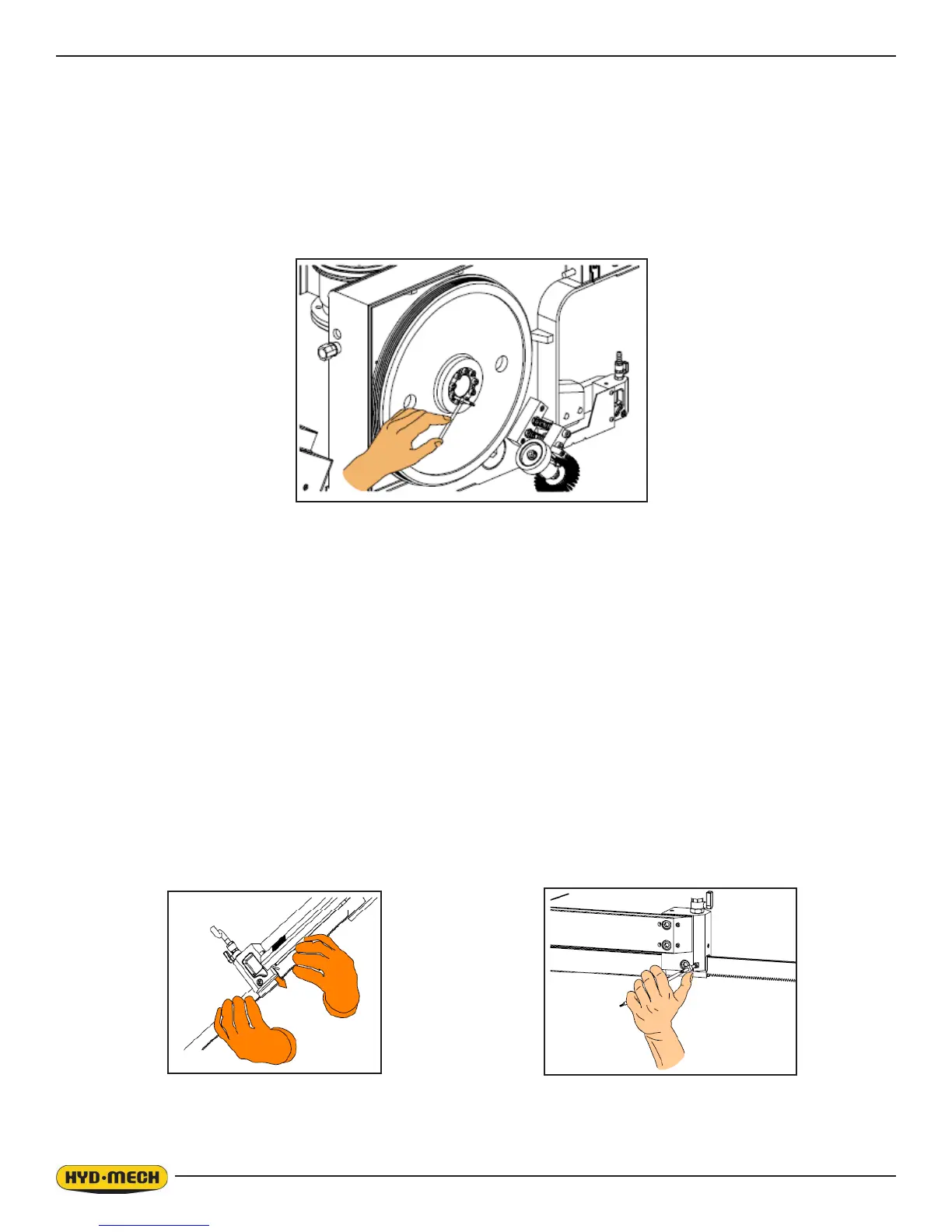

The Drive Wheel adjustment is closely linked to adjustment of the Idler Wheel. The purpose of the adjustment is to ensure

that the back of the blade remains about .040-.080” away from the wheel ange during rotation.

1. Open wheel cover.

2. Loosen all the screws on the wheel and manually move it in or out until the blade is correctly distanced from

the wheel ange.

3. Restore the machine and run blade for few wheel rotations.

4. Check the distance between the blade and wheels ange.

5. If necessary repeat steps until proper gap is achieved

BLADE GUIDE ADJUSTMENT

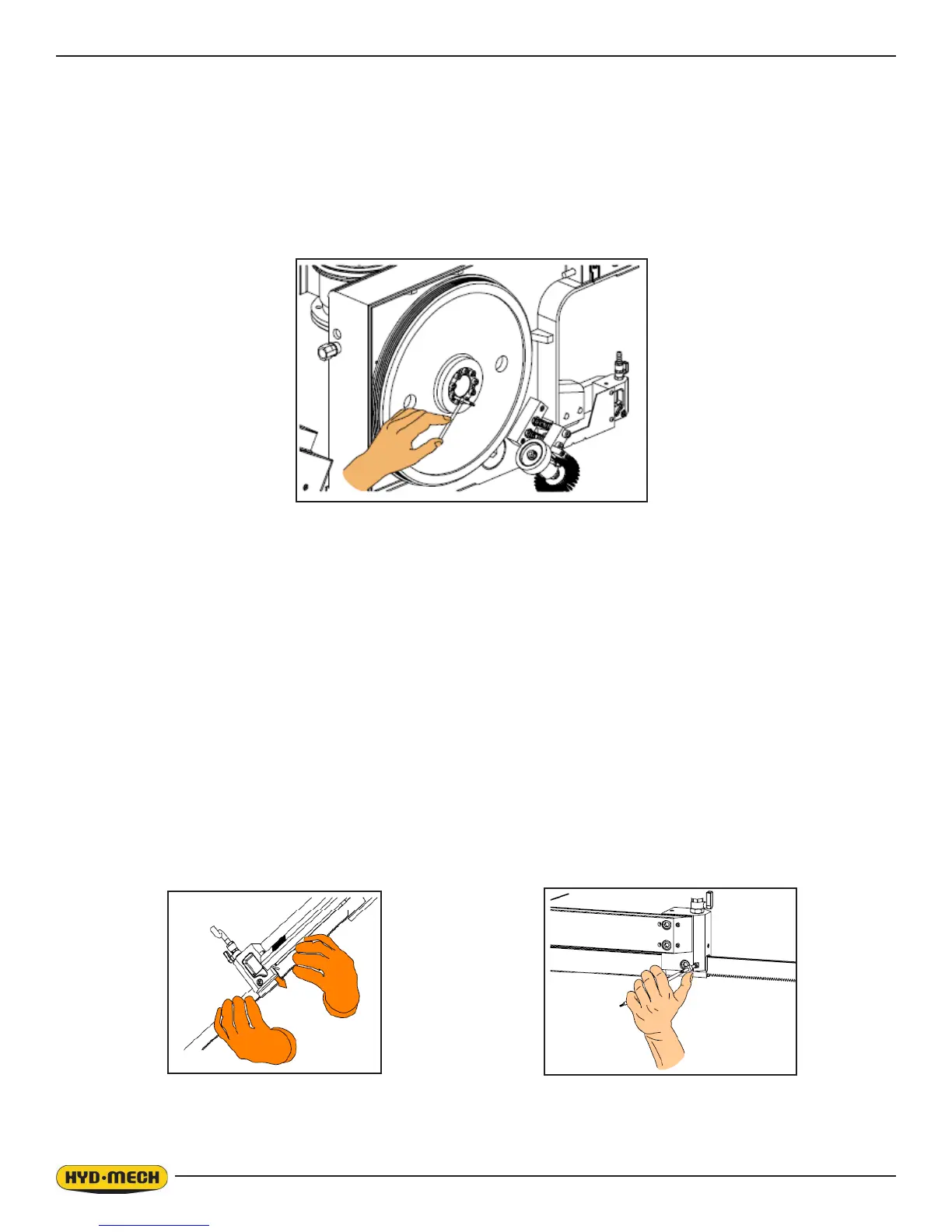

At the bottom of the guide arms are the blade guide block assemblies with carbide pads. These assemblies will need to be

adjusted occasionally as the carbide pads become worn, or if a blade with different thickness is used. To adjust properly,

follow this simple procedure.

1. Make sure there is a small amount of play between the blade and guide carbides. The blade band should be snug

but able to move freely up and down.

2. If the amount of play is not sufcient for the blade to run smoothly, adjust the locking torque of the screws with an

Allen key

Loading...

Loading...