3.5

CARBIDE REPLACEMENT

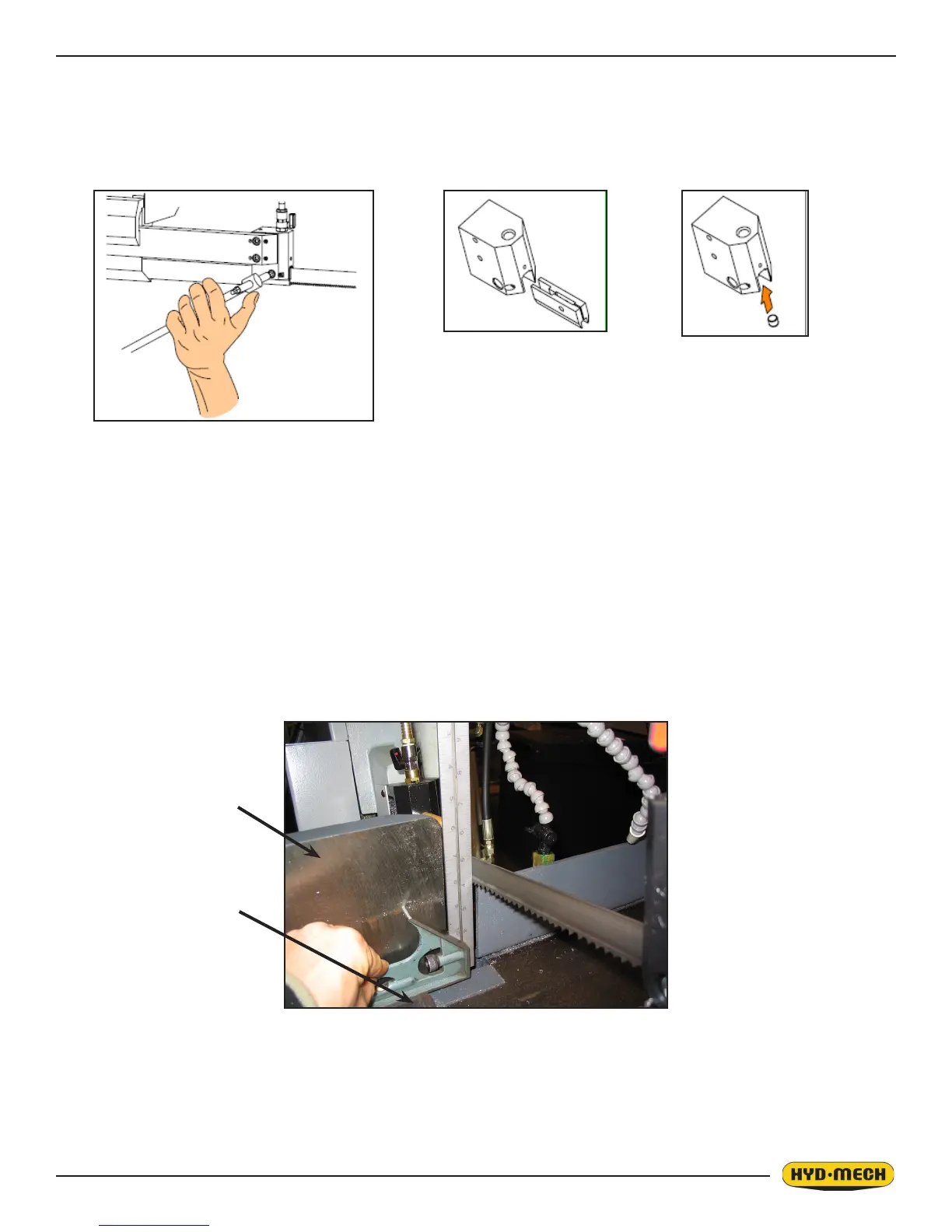

The blade guide blocks are equipped with one top carbide and two side carbide inserts each. The working life of carbide

guides is practically the same as that of the machine itself. However, if required they can be replaced by removing the

plate xing screw as shown.

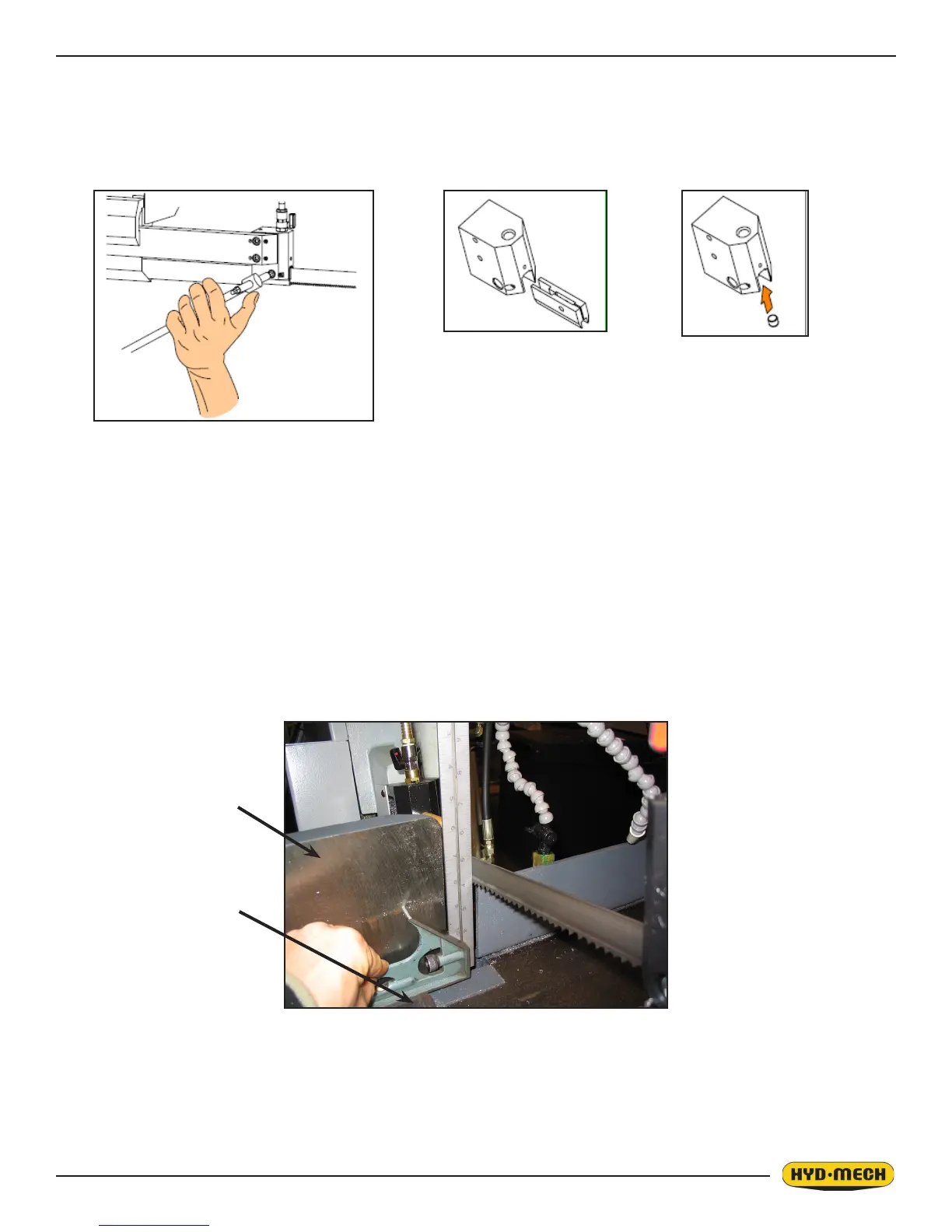

BLADE PERPENDICULARITY

The perpendicularity of the blade to the work table and proper blade tension are vital for achieving straight cut. This

adjustment is carried out using a workshop square, which should be placed against the side of the blade while resting on

the work table in the middle of the guide arm span. The square edge should contact the blade uniformly along the whole

blade width. Follow the procedure below if the guides need to be adjusted to achieve the proper blade perpendicularity.

1. Disconnect machine from power.

2. Open the vise.

3. Position the square on the clean work surface of the infeed table against the blade close to the datum jaw at a

point where the blade teeth do not prevent contact.

The top carbide is press t into the guide block. If the

top carbide needs replacement the whole guide block

has to be changed.

Datum Jaw

Infeed Table

Loading...

Loading...