1.2

LIFTING THE S20P WITH A FORK LIFT

The S20P is shipped with a shipping pallet attached to the saw. When lifting the pallet with a forklift truck make sure that

the load is rmly balanced. Minimum fork length of 72" (1827 mm) is recommended to safely lift the pallet.

WRAPPED FOR SHIPPING

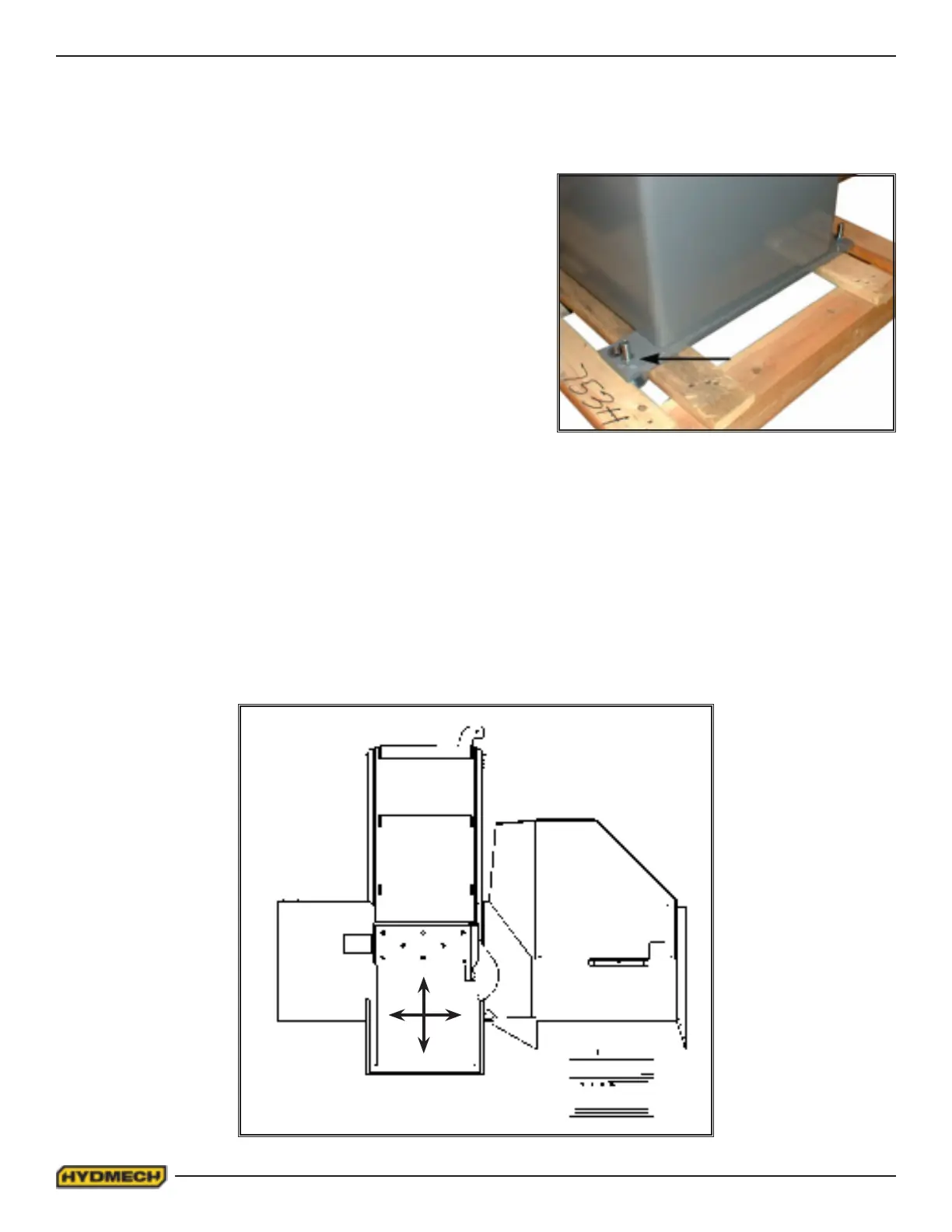

The S20P is shrink-wrapped for shipping from our plant. Remove the

wrapping from around the saw. Complete the inspection for signs of

damage. Undo the bolts that hold the saw to the pallet. Retain these

bolts to use for leveling. The following photo illustrates the oor mount-

ing plates located at the corners of the saw.

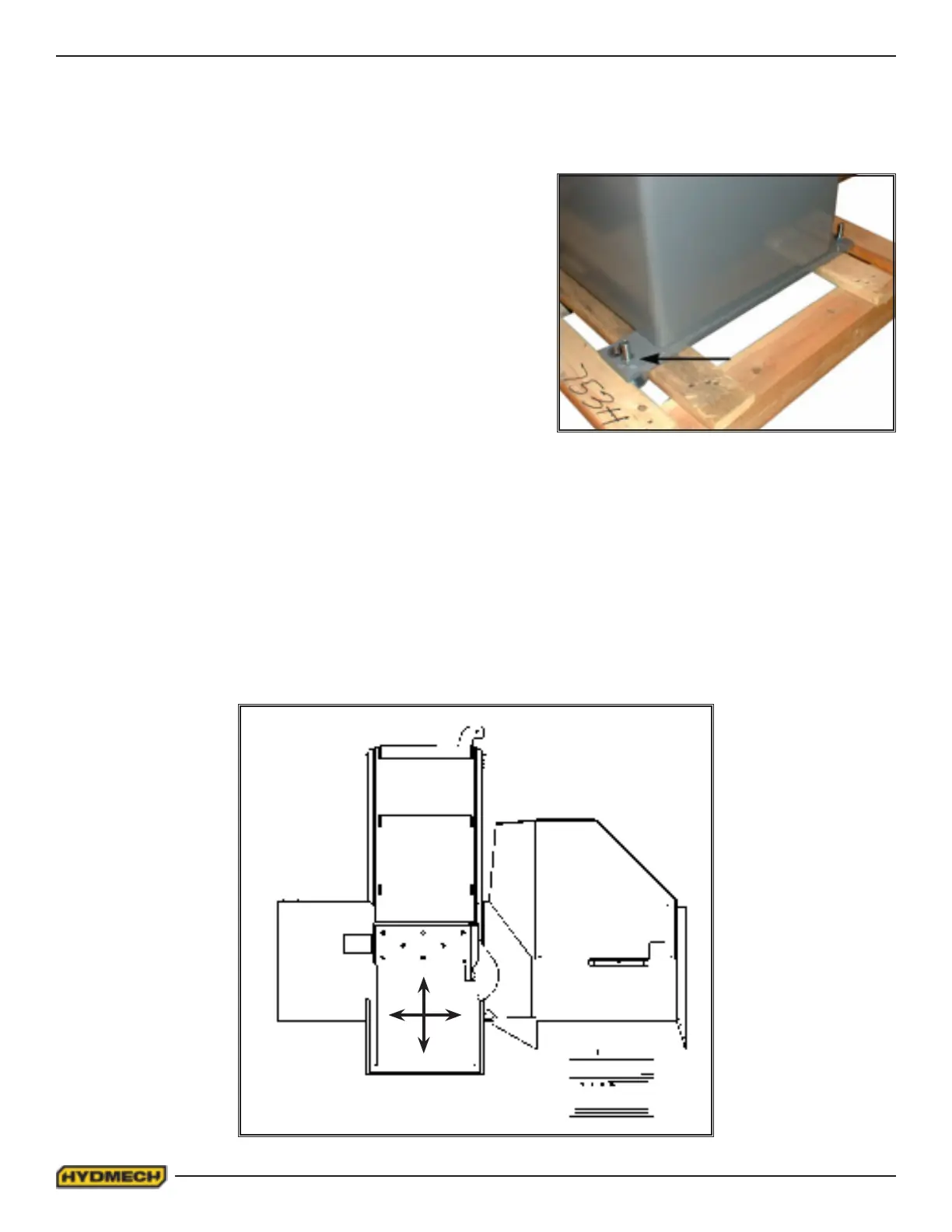

FOUNDATION, LEVELLING AND ANCHORING

Machine location should be carefully selected. A at concrete oor area should be chosen. It should have enough free

space surrounding the machine to enable free access for safe operation and maintenance. The machine should be lev-

eled in both directions (from side to side & from front to back). Six leveling screws used for securing the machine to the

pallet during transport, should be installed, one in each corner of the machine base, as shown below. It might be required

to place steel plates under leveling bolts to prevent their sinking into the concrete oor. In cases when the machine is to

be anchored permanently, anchoring holes are provided. They are located next to the leveling screw holes. The larger

diameter hole is used for retaining during shipping and for use with concrete oor anchors. The smaller diameter threaded

hole at each corner, are used for leveling the saw.

Using a level on the machine out-feed table, level machine front to back and side to side.

NOTE: In some cases leveling the saw infeed with a slight slope towards the blade is recommended. This will prevent

coolant from running down the raw stock. (This is especially true when cutting tubing or bundles).

Loading...

Loading...