7.1

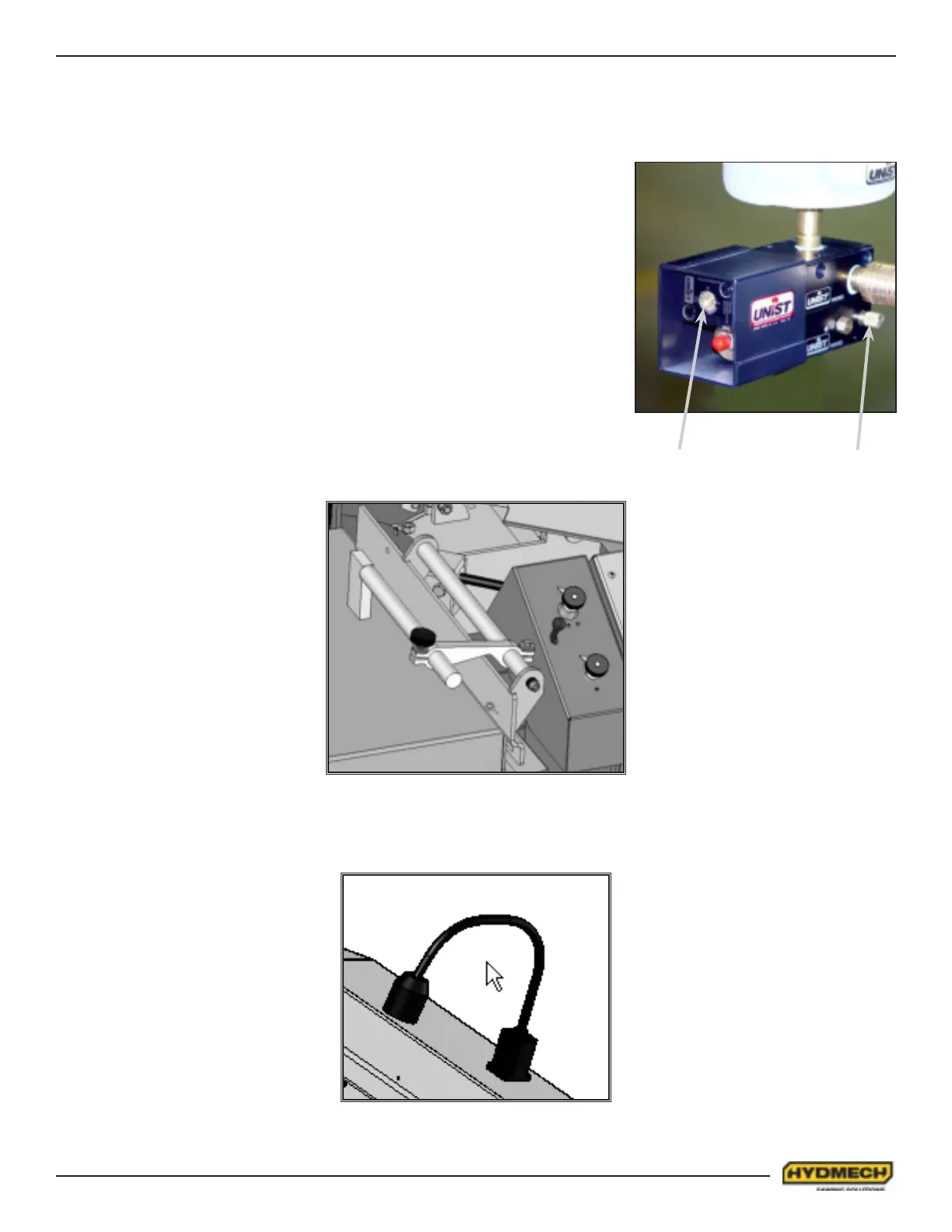

PULSE / MINUTE

AIR SCREW

MIST COOLANT SYSTEM

Mist Coolant – the air powered pump delivers a regulated number of pulses of lubri-

cant to a single applicator nozzle.

The unit has two control screws.

Pulse / Minute – adjusts rate of lubricant use. About 8 to 12 pulse per minute is

optimum – more is not better.

Air Screw – regulates the jet of air that projects the lubricant from the nozzle onto

the blade. Adjustment should be such that lubricant covers the blade without blow-

ing the mist beyond the back edge of the blade.

Note: New blade may require initial lubrication with a small quantity of mist coolant

applied to the blade at the idler guide arm to prevent squealing.

SECTION 7 - OPTIONAL EQUIPMENT

WORK STOP ASSEMBLY

Work Stop Assembly S20M-G17-00

WORK LAMP ASSEMBLY

Lamp 24VDC 20W #371789

FOR OPTIONAL ASSEMBLIES SEE PDF ON ATTACHED CD

Loading...

Loading...