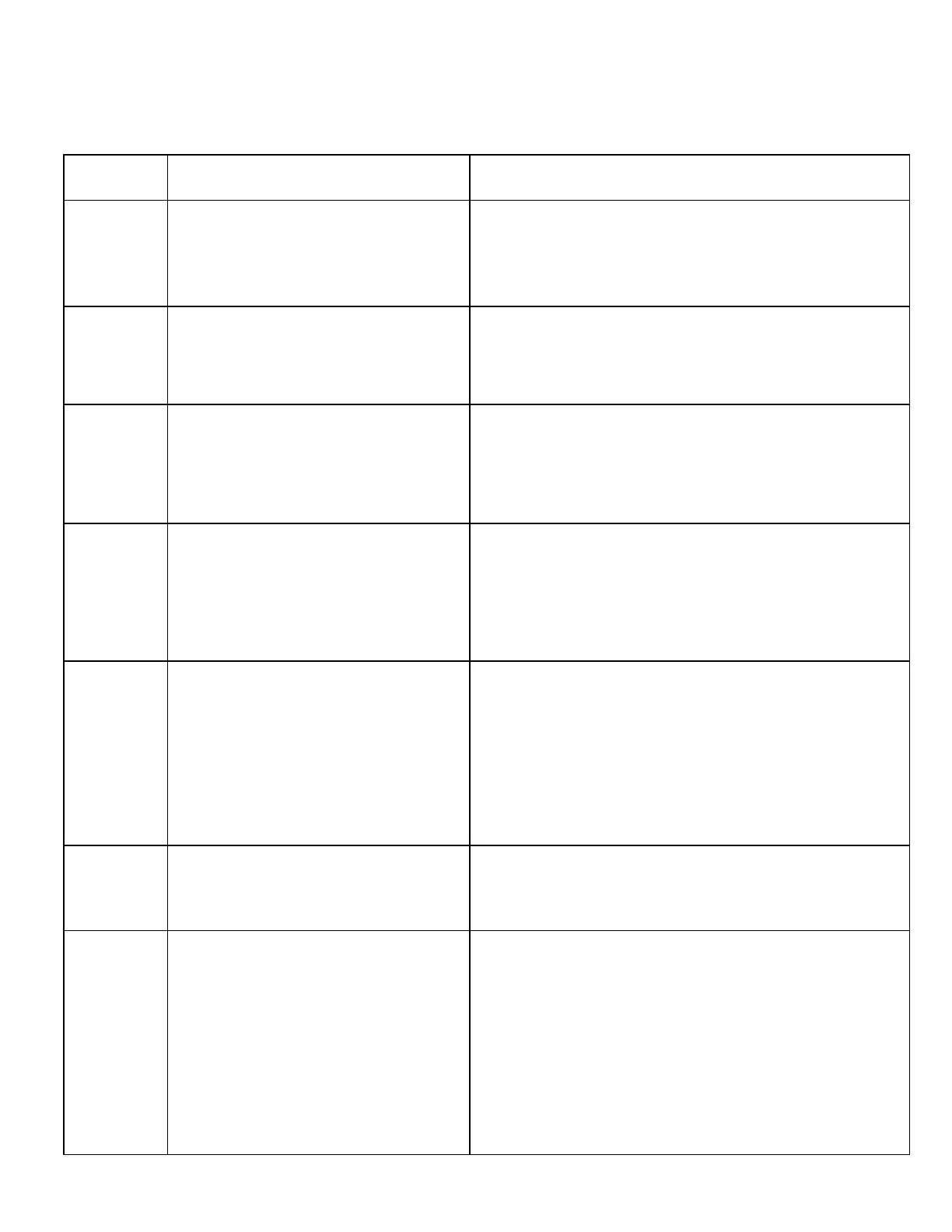

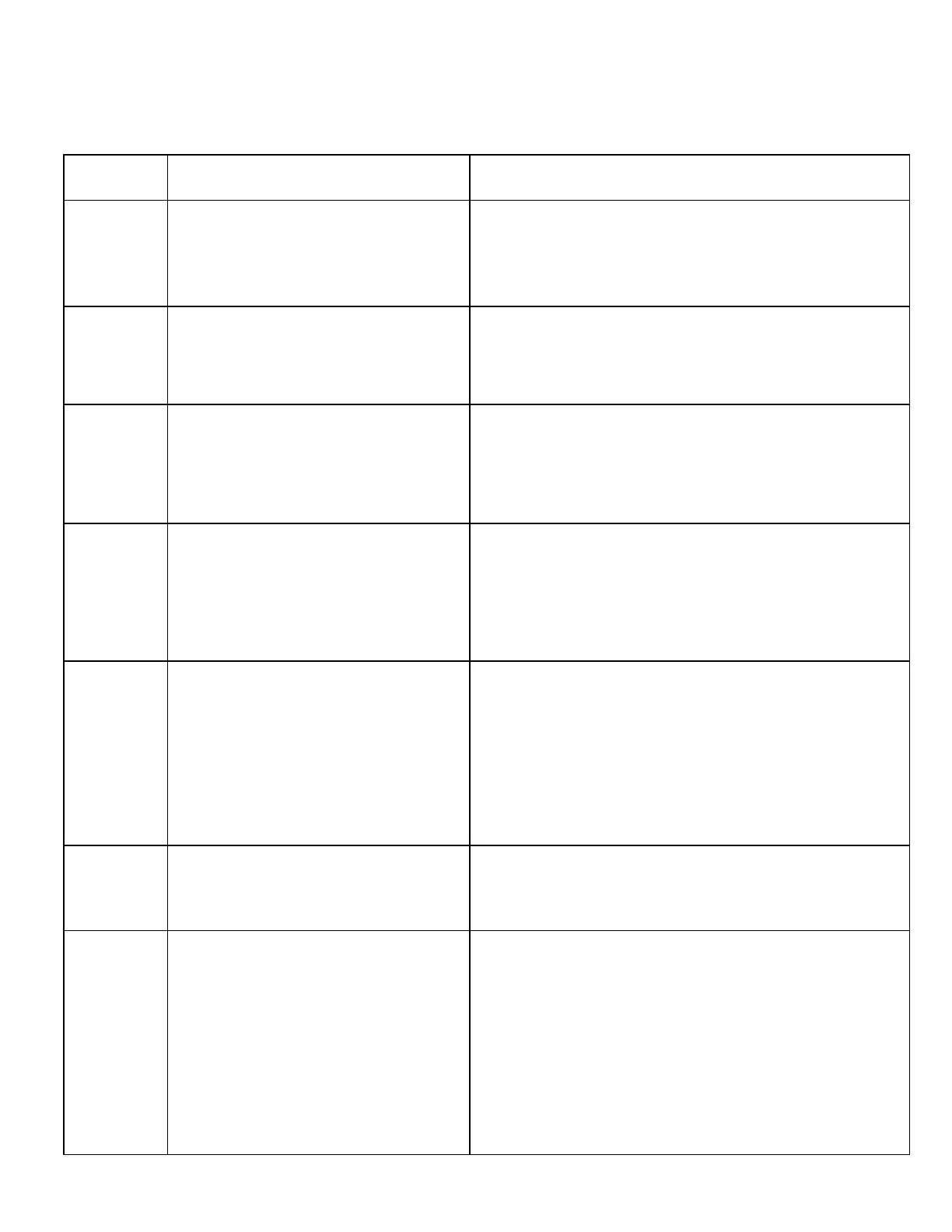

TROUBLESHOOTING

Although HydraMaster blowers are well designed and manufactured, problems may occur due to normal wear and

the need for readjustment. The chart below lists symptoms that may occur along with probable causes and

remedies.

8

SYMPTOM PROBABLE CAUSE REMEDIES

Loss of oil. Gear housing not tightened properly.

Lip seal failure.

Insufficient sealant.

Tighten gear housing bolts.

Disassemble and replace lip seal.

Remove gear housing and replace sealant.

Excessive

bearing or

gear wear.

Improper lubrication.

Excessive belt tension.

Correct oil level. Replace dirty oil. (See Lubrication section on

page 6)

Check belt manufacturer’s specifications for tension and adjust

accordingly.

Lack of vol-

ume.

Slipping belts.

Worn lobe clearances.

Speed too low.

Check belt manufacturer’s specifications for tension and adjust

accordingly.

Check for proper clearances (See Assembly Clearances on

page 10)

Increase blower speed within limits.

Knocking. Unit out of time.

Distortion due to improper mounting or

pipe strains.

Excessive pressure differential.

Re-time.

Check mounting alignment and relieve pipe strains.

Reduce to manufacturer’s recommended pressure.

Excessive

blower tem-

perature.

Too much or too little oil in gear reservoir.

Too low operating speed.

Clogged filter or silencer.

Excessive pressure differential.

Elevated inlet temperature.

Worn lobe clearances.

Check oil level. (See Lubrication section on page 6)

Increase blower speed within limits.

Remove cause of obstruction.

Reduce pressure differential across the blower.

Reduce inlet temperature.

Check for proper clearances (See Assembly Clearances on

page 10)

Rotor end or

tip drag.

Insufficient assembled clearances.

Case or frame distortion.

Excessive operating pressure.

Correct clearances. Check mounting and pipe strain.

Reduce pressure differential.

Reduce pressure differential or reduce inlet temperature.

Vibration. Belt or coupling misalignment.

Lobes rubbing.

Worn bearings or gears.

Unbalanced or rubbing lobes.

Driver or blower loose.

Piping resonance.

Check carefully, realign if necessary.

Check cylinder for hot spots, then check for lobe contact at

these points. Correct clearances (See Assembly Clearances on

page 10)

Check condition of gears and bearings; replace if necessary.

Possible buildup on casing or lobes, or inside lobes. Remove

buildup and restore clearances.

Check mounting and tighten if necessary.

Check pipe supports, check resonance of nearby equipment,

check foundation

Loading...

Loading...