DRIVER

T

M

Z-ME-KZ

O1

O2

O3

O4

O5

O6

O7

A3

A4

A5

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

X1 X2

OK

DWN

UP

ENT

ESC

RS232

PROFIBUS

A B

PT

DRIVER

P

T

AB

PT

M

Z-ME-KZ

O1

O2

O3

O4

O5

O6

O7

A3

A4

A5

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

X1 X2

OK

DWN

UP

ENT

ESC

RS232

PROFIBUS

P

DRIVER

P

T

AB

PT

M

Z-ME-KZ

O1

O2

O3

O4

O5

O6

O7

A3

A4

A5

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

X1 X2

OK

DWN

UP

ENT

ESC

RS232

PROFIBUS

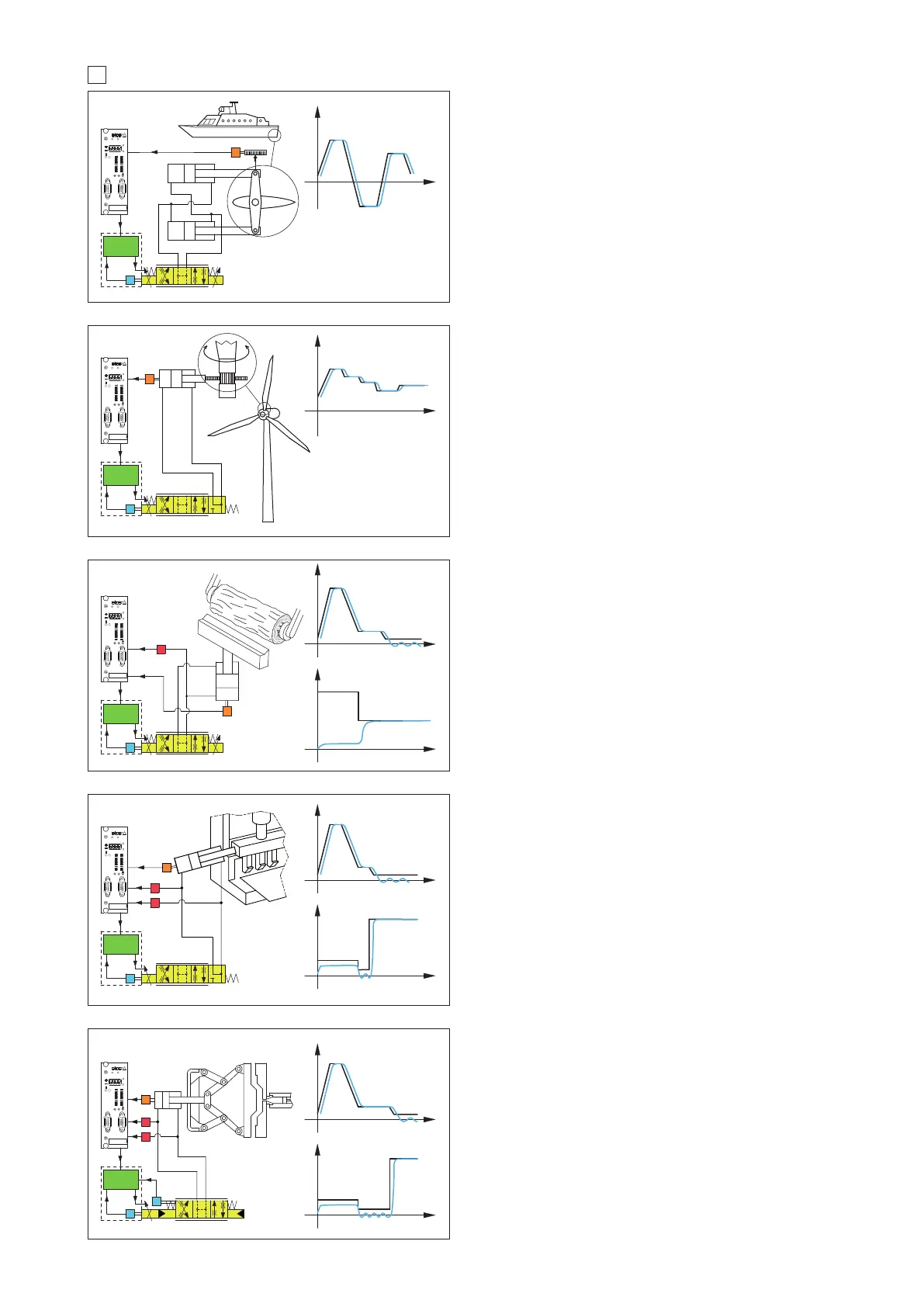

Wood machinery

Hydraulic steering wheel in marine applications

Rudder controls on motor yachts and sail boats requires smooth control

for precise and reliable operations.

Z-ME-KZ controllers perform the rudder position control system, ensuring

accurate and repetitive regulations for a comfortable ride, thanks to:

- analog position reference mode for real time controls

- potentiometer position transducer for simple and compact solution

- position PID control parameters to optimize the system response

- complete diagnostic information for advanced system monitoring

Wind turbines

The pitch control of the rotor blades is required to maximize the energy pro-

duction. Accurate positioning, decentralized intelligence as well as long ser-

vice life and reliability are required.

Z-ME-KZ controllers perform high quality regulation of the blade pitch

simplifying the system architecture, thanks to:

- SSI digital position transducer for high precision control

- complete remote system management with fieldbus interface

- position PID selection to adapt the position control to the different wind

conditions

APPLICATION EXAMPLES

5

Bending Machines

Die-casting machinery

Clamp movements in die-casting phases involve fast/slow motion cycle with

accurate and repetitive alternated position/force controls for the mould safety

functions.

Z-ME-KZ controllers, with alternated position/force control, simplify the

hydraulic + electronic system architecture, thanks to:

- internal reference generation for repetitive working cycles

- SSI digital position transducer for accurate axis control

- two pressure transducers for alternated force control

- auxiliary digital inputs/output to synchronize the machine functions

- fieldbus connection for machine remote control and advanced diagnostics

DRIVER

T

AB

PT

Z-ME-KZ

O1

O2

O3

O4

O5

O6

O7

A3

A4

A5

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

X1 X2

OK

DWN

UP

ENT

ESC

RS232

PROFIBUS

M

T

P

P

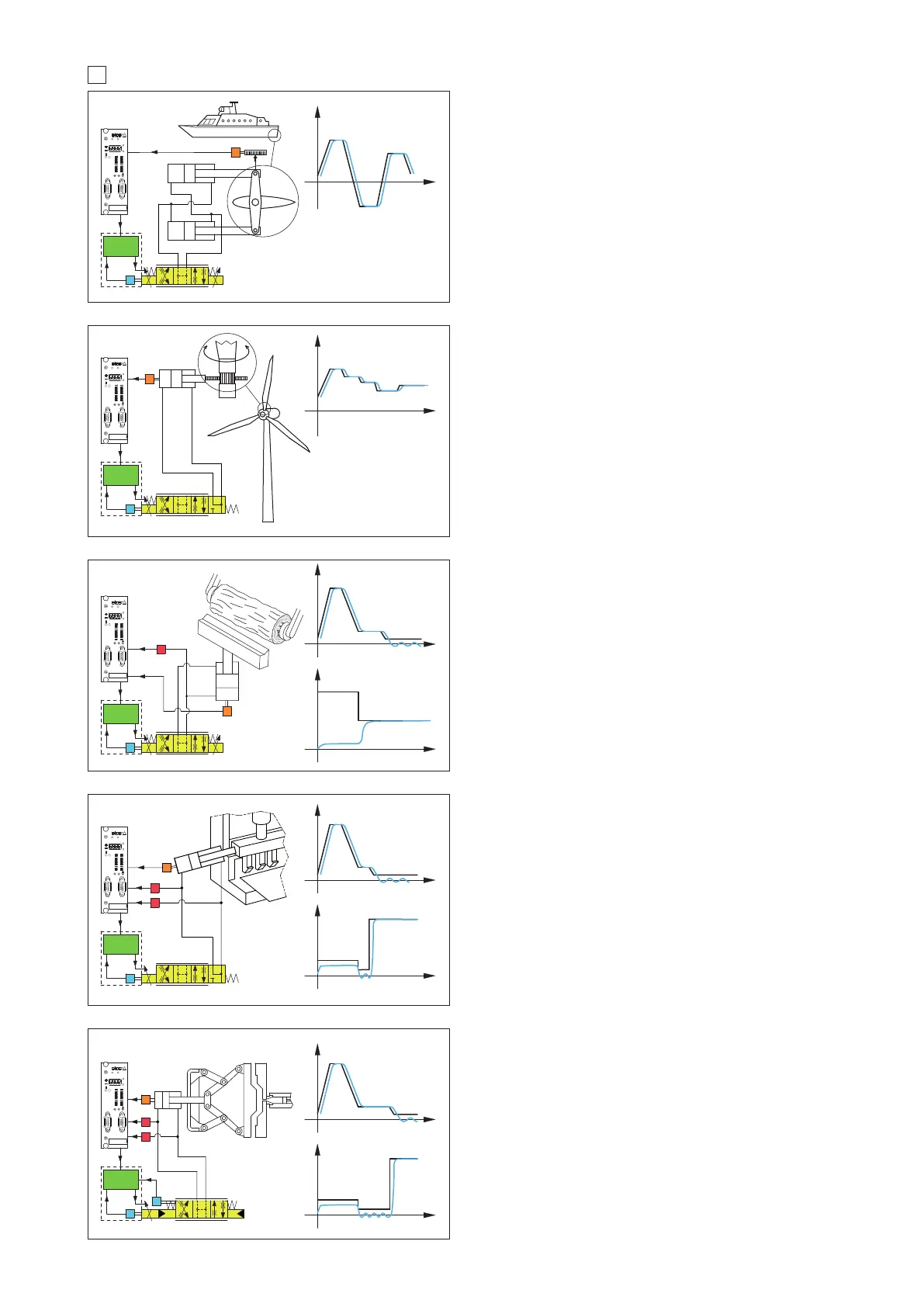

Machine tools for cold-forming flat sheets require complete, automatic,

programmable and flexible machine control to produce sheet metal panels

from punched blank.

Z-ME-KZ controller combine high level position regulation with accurate

force control to provide in a single device a complete and dedicated

solution, thanks to:

- internal reference generation to simplify the machine control cycle

- digital position sensor for high resolution measurement system

- two pressure transducers for alternated force control

- fieldbus interface for easy machine control integration

- auxiliary digital outputs for system status indication (target reached, force

control active)

Hydraulic wood machines require configurable and repetitive motion

profiles, accurate position controls, and digital signals for synchronization

purpose.

Z-ME-KZ controllers allow remote control, thanks to:

- internal reference generation with maximum speed and acceleration settings

- analog position transducer for simple and reliable solution

- pressure transducer for alternated pressure control

- fieldbus connection for remote parameterization, commands, and controller

state indication

G340

DRIVER

T

AB

PT

Z-ME-KZ

O1

O2

O3

O4

O5

O6

O7

A3

A4

A5

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

X1 X2

OK

DWN

UP

ENT

ESC

RS232

PROFIBUS

M

Position control

Position control

Position control

Position control

Position control

Position

Position

t

t

Speed profile generated

t

t

Pressure

Speed profile generated

t

t

Force

Speed profile generated

t

t

Force

Loading...

Loading...