Z-ME-KZ

DWN

ENT

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

O1

O2

O3

O4

O5

O6

O7

A3

A4

A5

ESC

UP

OK

X1 X2

RS232

PROFIBUS

9 FRONT PANEL VIEW

Function Keys

Display

Active Led

OK Led

Digital Input Led

Digital Output Led

Auxiliary Led

Test Points

RS232 serial programming port

PROFIBUS-DP port (*)

(*) only for -BP option

8 FRONT PANEL DESCRIPTION

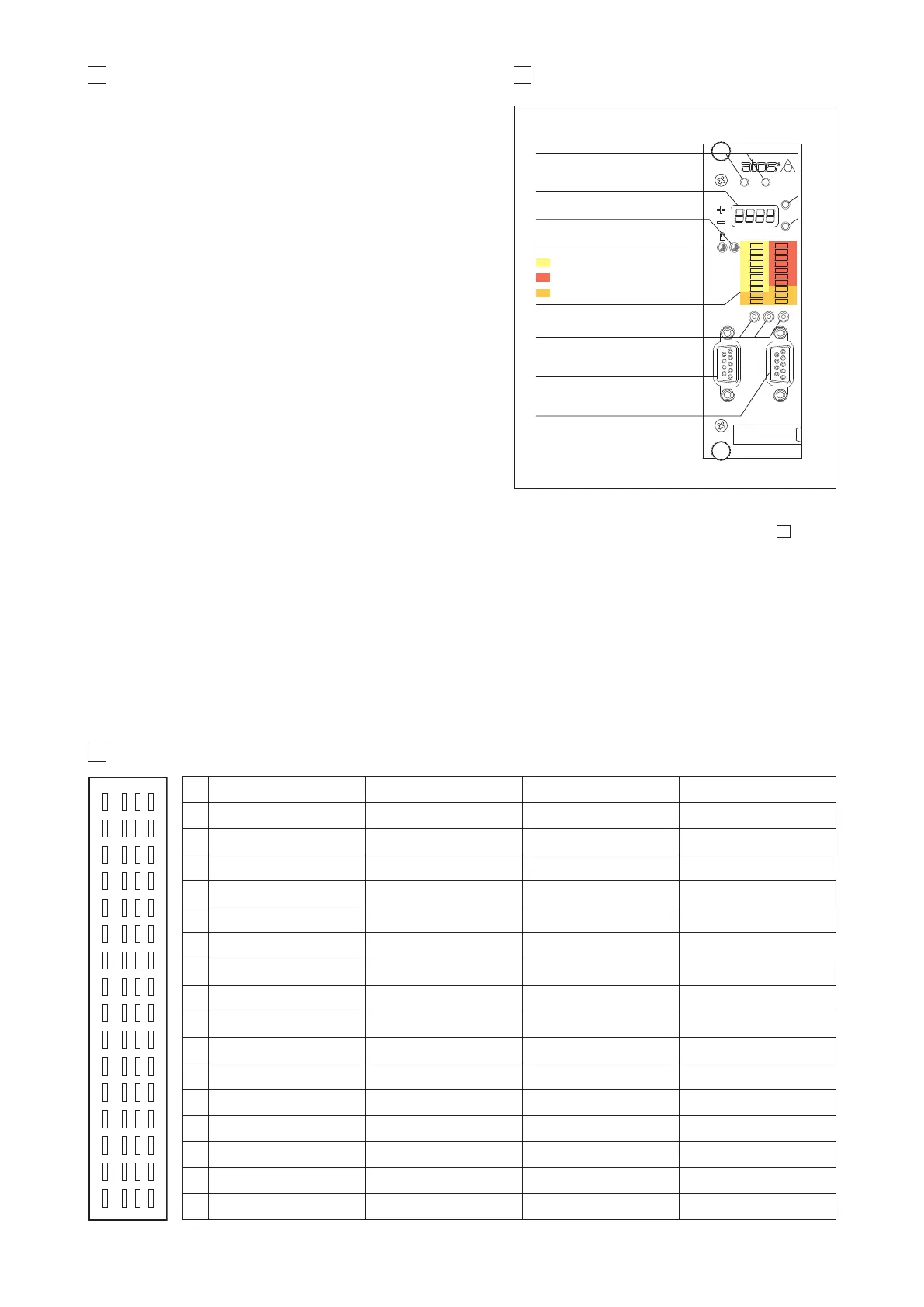

10 ELECTRONIC CONNECTIONS - 64 PIN REAR CONNECTOR

pin f d b z

2

DO 7 DI 1 F_TR2 + nc

4

SSI clock + DI 2 F_TR2 - nc

6

SSI clock - DI 3 F_INPUT + nc

8

SSI data + / Inc Ua1 DI 4 F_INPUT - nc

10

SSI data - / Inc /Ua1 DI 5 P_INPUT + nc

12

Inc Ua2 DI 6 P_INPUT - nc

14

Inc /Ua2 DI 7 F_TR1 + nc

16

Inc Ua0 DI 8 F_TR1 - nc

18

Inc /Ua0 ENABLE P_TR + nc

20

Inc +5VDC DO 1 P_TR - GND

22

nc FAULT VALVE_MONITOR + DO 3

24

nc nc VALVE_MONITOR - DO 4

26

nc DO 2 P_MONITOR + DO 5

28

CAN_GND nc AGND DO 6

30

CAN_L CONTROL_OUTPUT + VREF -10VDC V+

32

CAN_H F_MONITOR + VREF +10VDC V0

zbdf

2

4

6

8

10

12

14

16

18

(I) Input - (O) Output - (D) Digital transducers - (PS) Power supply - (F) Fieldbus interface, only for -BC option

20

22

24

26

28

30

32

rear view

(O)

(D)

(D)

(D)

(D)

(D)

(D)

(D)

(D)

(O)

(F)

(F)

(F)

(I)

(I)

(I)

(I)

(I)

(I)

(I)

(I)

(I)

(O)

(O)

(O)

(O)

(O)

(I)

(I)

(I)

(I)

(I)

(I)

(I)

(I)

(I)

(I)

(I)

(I)

(O)

(O)

(O)

(O)

(O)

(O)

(O)

(PS)

(PS)

G340

8.1 Keyboard and display

On the Z-ME-KZ front panel are available 4 function keys (ESC, ENT, UP, DWN),

and a numeric display (4 digits plus sign) to allow the user to view and change

the controller’s parameters as well as to display diagnostic messages.

The following parameters can be accessed (viewed or changed) via correspon-

ding menu structure:

- command and actual values

- analog input / output values

- digital input / output status

- position sensor indication

- force / pressure sensor indication

Parameter’s changes of the configuration, control gains, trigger conditions, inter-

nal cycle, fault monitoring are not allowed via front panel operations.

8.2 LED indication

The led indications are used to display the internal status (Active, OK) of the con-

troller or the status of the digital IO of the Z-ME-KZ. There are 22 led divided in

four different types:

- internal controller’s status (Active - OK)

- digital input status (I1 ÷ I8)

- digital output status (O1 ÷ O7)

- software programmable led (A1 ÷ A5) for specific functions

8.3 Test points

The test points present on the controller front panel can be used to monitor the

actual position (X1) and the force / pressure (X2) value measured by the relevant

transducers. Both signals are referred to the analog ground (

┴

) pin. The two

signals are respectively connected to P_MONITOR+ (X1) and F_MONITOR+ (X2)

analog output present on the rear connector of the controller card. These signals

can be software set to show other signals available in the controller (see 11.8 and 11.9).

8.4 Communication ports

On the front panel of the Z-ME-KZ is always present a serial RS232 port to program the controller by the Atos Z-SW software (see section ). All the

functional parameters of digital controller, like internal reference generation, controller dynamics, IO configurations, can be easily set and optimized by

the user.

For -BP or -BC options a second communication port dedicated to the selected fieldbus connection is present on the controller. For -BP option the

PROFIBUS-DP port is located on the front panel of the Z-ME-KZ controller. For -BC option the CANopen connection is located on the rear connector of the

Z-ME-KZ controller.

Through the fieldbus communication only the real-time parameters may be exchanged:

- position, velocity and force / pressure reference

- position, velocity and force / pressure feedback

- controller commands and status

- diagnostic / error messages

For more information about the front panel settings and fieldbus communication, please refer to the controller user manual.

12

Loading...

Loading...