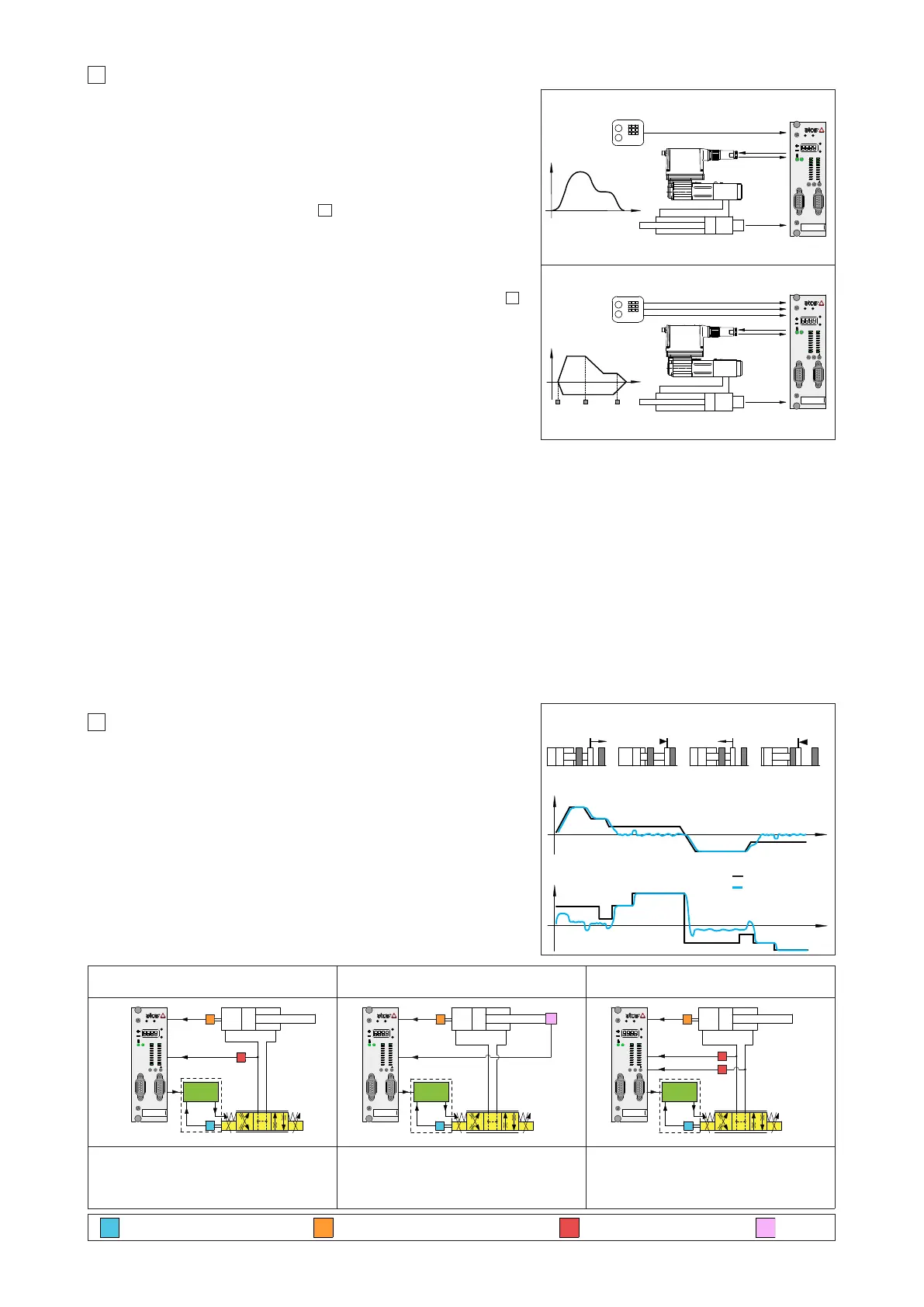

3 POSITION REFERENCE MODE

3.1 External reference generation

Z-ME-KZ controller regulates in closed loop the actuator position according to an external

reference position signal and to the position feedback from the actuator transducer. It

generates a reference signal for the proportional valve which regulates the hydraulic flow

to the actuator.

The external reference signal can be software selected among:

Analog reference (a)

The controller receives in real time the reference signal from the machine electronic central

unit by means of the analog input (see section ) limiting speed, acceleration and dece-

leration values.

Fieldbus reference (b)

The controller receives in real time the reference signal from the machine electronic central

unit by means of the digital fieldbus communication (-BC and -BP executions) limiting

speed, acceleration and deceleration values.

For fieldbus communication details, please refer to the controller user manual (see section ).

3.2 Internal reference generation

Z-ME-KZ controller regulates in closed loop the actuator position according to an internally

generated reference position signal and to the position feedback from the actuator tran-

sducer. It generates a reference signal for the proportional valve which regulates the

hydraulic flow to the actuator.

The internal reference signal is generated by a pre-programmed cycle; only start, stop and

switch-over commands are required from the machine electronic central unit by means of:

- on-off commands (c)

- fieldbus commands (d)

12

10

4

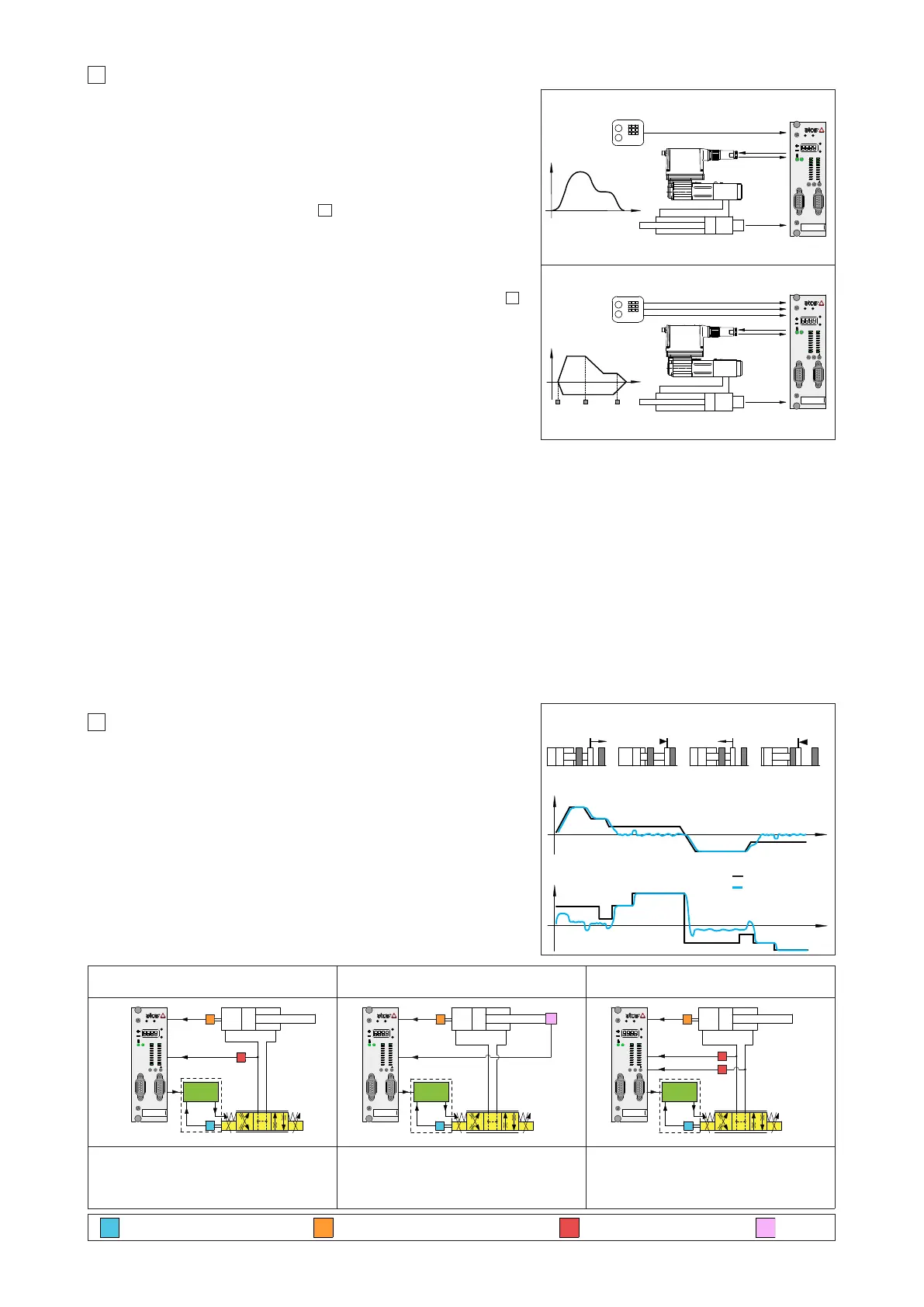

POSITION / PRESSURE OR FORCE CONTROL

Alternated pressure or force control can be added to the actuator’s standard position con-

trol (see below functional schemes).

Remote transducers (pressure or force) have to be installed on the actuator.

The position/pressure (or position/force) controls are operated according to two separate

reference signals and a dedicated algorithm automatically selects which control is active

time by time.

The dynamics of the switching between the two controls can be regulated thanks to speci-

fic software setting, in order to avoid instability and vibrations.

Position control is active (see phase and at side) when the actuator actual pressure

or force is lower than the relevant reference signal.

Pressure or force control is active (see phase and at side) when the actuator actual

pressure or force, measured by remote transducers, grows up to the relevant reference

signal - the controller reduces the valve’s regulation in order to limit the actuator pressure

or force; if the pressure or force tends to decrease under its reference signal, the position

control returns active.

Alternated Position/Pressure Control Alternated Position/Force Control - Load cell

Alternated Position/Force Control - Two pres-

sure transducers

DRIVER

P

T

AB

PT

M

Z-ME-KZ

O1

O2

O3

O4

O5

O6

O7

A3

A4

A5

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

X1 X2

OK

DWN

UP

ENT

ESC

RS232

PROFIBUS

DRIVER

T

AB

PT

M

L

Z-ME-KZ

O1

O2

O3

O4

O5

O6

O7

A3

A4

A5

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

X1 X2

OK

DWN

UP

ENT

ESC

RS232

PROFIBUS

DRIVER

T

AB

PT

M

P

P

Z-ME-KZ

O1

O2

O3

O4

O5

O6

O7

A3

A4

A5

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

X1 X2

OK

DWN

UP

ENT

ESC

RS232

PROFIBUS

one remote pressure transducer has to be

installed on the actuator’s port to be controlled

one load cell transducer has to be installed

between the actuator and the controlled load

two remote pressure transducers have to be

installed on the actuator’s ports; the actuator

force is calculated by the pressure feedbacks

(Pa - Pb)

valve’s spool transducer actuator’s position transducer pressure transducer load cell

M

Z-ME-KZ

O1

O2

O3

O4

O5

O6

O7

A3

A4

A5

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

ESC

ENT

UP

DWN

OK

X1 X2

RS232

PROFIBUS

M

Z-ME-KZ

O1

O2

O3

O4

O5

O6

O7

A3

A4

A5

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

ESC

ENT

UP

DWN

OK

X1 X2

RS232

PROFIBUS

t

t

External reference generation

Internal reference generation

force

forward

movement

backward

movement

force

control

force

control

reference value

actual value

Atos PC software allows to design a customized sequence of motion phases adapted to the specific application requirements: a range of predefined

standard sequences are available in the Z-SW software.

Start/stop/switch-over commands and reference generation type can be set for each phase in order to realize an automatic cycle according to the appli-

cation requests. Refer to the controller user manual for further details on the available selection of start/stop/switch-over commands and reference gene-

ration type.

Start/stop/switch-over commands examples

External digital input on-off commands, on rear connector, are used to start/stop the cycle generation or to change the motion phase

External fieldbus input on-off commands, by fieldbus communication, are used to start/stop the cycle generation or to change the motion phase

Switch by position switch-over from actual to following motion phase occurs when the actual position reaches a programmed value

Switch by time switch-over from actual to following motion phase occurs after a fixed time, starting from the actual phase activation

Switch by internal status switch-over from internal status are used to start/stop the cycle generation or to change the motion phase

Internal reference generation types examples

Absolute a target position reference signal is internally generated for each motion phase; maximum speed, acceleration and

deceleration can be set to obtain a smooth and precise position control

Relative as ‘Absolute’ but the target position corresponds to the actuator position plus a fixed quote internally set by software

Hold the controller holds the actual position

Machine

central unit

Machine

central unit

Analog

(a) or Fieldbus (b)

reference

Valve command

and monitor

position

t

Valve command

and monitor

On-off

(c) or Fieldbus (d)

commands

pos

Speed profile generated

switch-over points

Speed profile generated

Loading...

Loading...