Digital position controllers type Z-ME-KZ

Eurocard format, for electrohydraulic closed loop controls

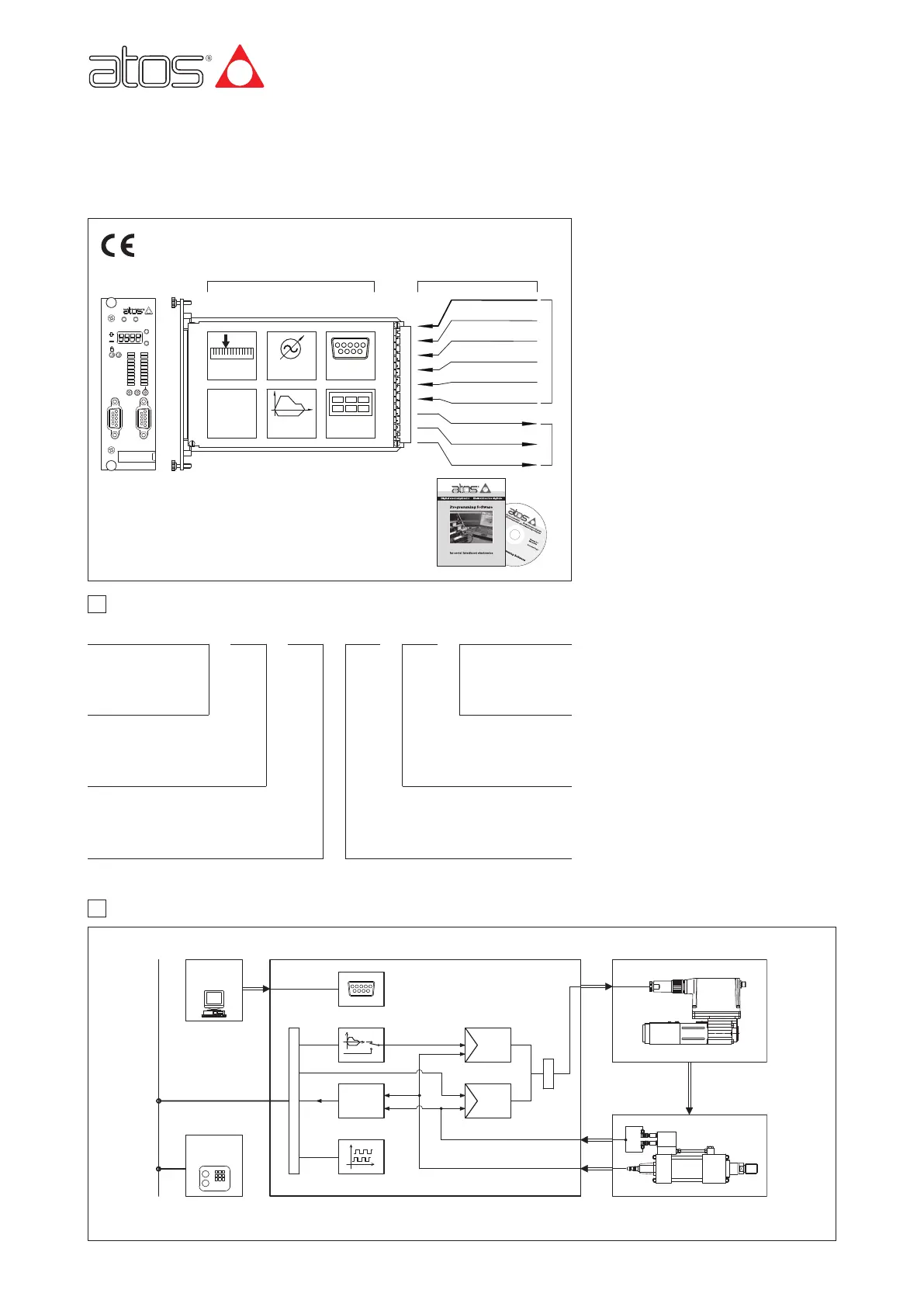

1

MODEL CODE

Z - ME KZ PS- ** /*

Electronic axis controller

in Eurocard format

Optional fieldbus communication interfaces:

- = standard without fieldbus interface

BC = CANopen communication interface

BP = PROFIBUS DP communication interface

Set code

G340

www.atos.com Table G340-6/E

P/Q

Z-SW-PS

SW-PS

Z-ME-KZ

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

O1

O2

O3

O4

O5

O6

O7

A3

A4

A5

X1 X2

OK

DWN

UP

ENT

ESC

RS232

PROFIBUS

Z-ME-KZ

-

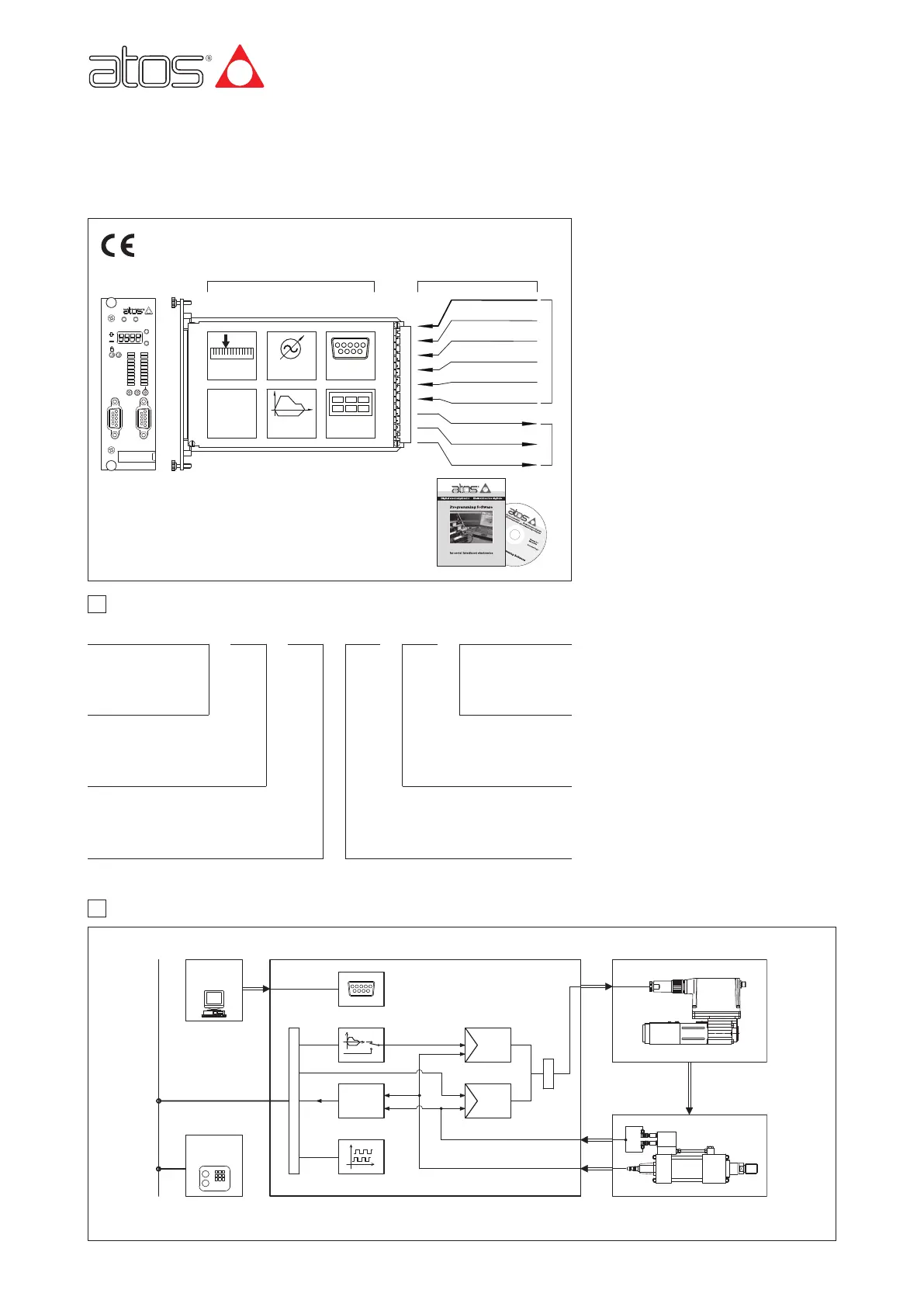

2 BLOCK DIAGRAM

Z-SW-PS

programming software

MAIN FUNCTIONS AND FEATURES USER INTERFACE

Position

control

Alternated

control

Real-time

fieldbus

Internal

reference

Enhanced

diagnostic

Serial port

SUPPLY 24V

POSITION REFERENCE

FORCE REFERENCE

POSITION FEEDBACK

FORCE FEEDBACK

AUXILIARY INPUT

DRIVER’S COMMAND

MONITOR

AUXILIARY OUTPUT

INPUTS

OUTPUTS

Alternated position / force

(or position / pressure) control module

Serial communication interface for configuration

and monitoring function

/ /**

Z-SW-PS

SOFTWARE

MACHINE

CENTRAL

UNIT

FIELDBUS NETWORK

SERIAL PORT

DIGITAL I/O

POSITION CONTROL

FORCE CONTROL

SETPOINT

GENERATOR

DIGITAL CONTROLLER Z-ME-KZ

FORCE / PRESSURE FEEDBACK

POSITION FEEDBACK

PROPORTIONAL VALVE

HYDRAULIC ACTUATOR

Note: Block diagram example for alternated position/force control, with fieldbus interface.

FIELDBUS

Z-ME-KZ digital axis controllers perform the

position closed loop of linear or rotative

hydraulic axes.

The controller receives a position feedback

from the axis transducer and it generates a

reference signal to the proportional valve

which regulates the hydraulic flow to the

actuator.

The position feedback interfaces are SSI,

incremental encoder, potentiometer or stan-

dard analog inputs (voltage or current)

software selectable.

A front panel serial port is always present for

configuration and monitoring of the controller.

The controller can be operated in real time

by external or internally generated reference

signal.

With external reference signal the actuator’s

motion cycle can be managed by either ana-

log or fieldbus reference input.

With internally generated reference signal the

actuator’s motion cycle can be managed by

external or fieldbus on/off commands.

A pressure/force alternated control may be

set by software additionally to the position

control: a pressure/force transducer has to

be assembled into the actuator and connec-

ted to the controller; a second reference

pressure/force signal is required.

Several auxiliary digital inputs/outputs are

available and they can be used to synchroni-

ze other machine functions and to transmit

information on the controller state.

Electrical Features:

• 4 digits front panel display to check and

change parameters as well as for diagno-

stics

• Front panel DB9 connector for serial pro-

gramming interface

• Front panel test points for debug and

maintenance

• Eurocard format (DIN 41494 - Plug-in-units)

• CE mark according to EMC directive

Software Features:

• Internal generation of motion cycle

• Setting of axis’s dynamic response (PID) to

optimize the application performances

• Software selectable range of electronic

reference analog inputs: voltage or current

• Enhanced diagnostics of the axis status

• Intuitive graphic interface

• In field firmware update through standard

serial communication

• Internal oscilloscope function

Series number

Loading...

Loading...