G025

6 INSTALLATION AND START-UP

It is advisable to perform calibration procedures in the order given below.

6.1 Warning

– Never insert or remove the driver while the electronic system is powered on.

– Protect the regulator on power line with an external fuse (2,5A RTV for version E-BM-AC-01F

and E-BM-AC-05F; 5A RTV for E-BM-AC-011F)

– Refer to section to identify components mentioned in calibration procedures.

– It is possible to install the E-BM-AC driver on front panel (drilling plane 33,5x68,5 mm) or on

back panel DIN guide (see fig. ).

The electrical connection is made on the clamps of the proper UNDECAL type E-K-11B socket,

equipped with antivibrating spring.

6.2 Start-up

Factory pre-set adjustments might not meet the requirements desired for the specific application.

Performances can be optimized by on-site re-adjustments of Bias, Scale and ramps potentiome-

ters, in sequence.

– Connect the electronic driver according to the desired connection diagram, (see

, ,

).

– The current supplied to the coil can be measured by a voltmeter connected between the test

points on the front panel.

The reading range will be: l[mA] = V[mV].

Bias adjustment (dead band compensation), see

, , .

For E-BM-AC-01F and E-BM-AC-11F:

– supply a reference signal voltage R1 = +0,2 V

DC

;

– turn clockwise the potentiometer P1 for solenoid S1 until the movement of the controlled actua-

tor is obtained.

– turn the potentiometer P1 in the opposite direction until the actuator is stopped.

– for version E-BM-AC-011F repeat the operation and supply a reference signal voltage R2 =

+0,2 V

DC

by the potentiometer P2.

For E-BM-AC-05F:

– supply a reference voltage R1 = +0,2 V

DC

;

– turn clockwise the potentiometer P1 for solenoid S1 until the movement of the controlled actua-

tor is obtained.

– turn the potentiometer P1 in the opposite direction until the actuator is stopped.

– repeat the operation and supply a reference signal voltage R1 = -0,2 V

DC

by the potentiometer

P2.

Scale adjustment (see

, ,

)

Supply max. reference signal voltage R1 (for E-BM-AC-05F driver repeat for max. negative referen-

ce voltage signal R1) in the specified range and turn scale potentiometer P3 (P4 for negative refe-

rence signal) until the actuator speed reaches the desired value.

For version E-BM-AC-011F repeat the operation and supply the max positive reference signal R2

by the potentiometer P4.

Ramps, see

,

.

Turning the ramp potentiometer(s) clockwise, acceleration(s) and deceleration(s) can be reduced

to obtain the optimization of the complete system.

97

11109

11109

15145

8

9

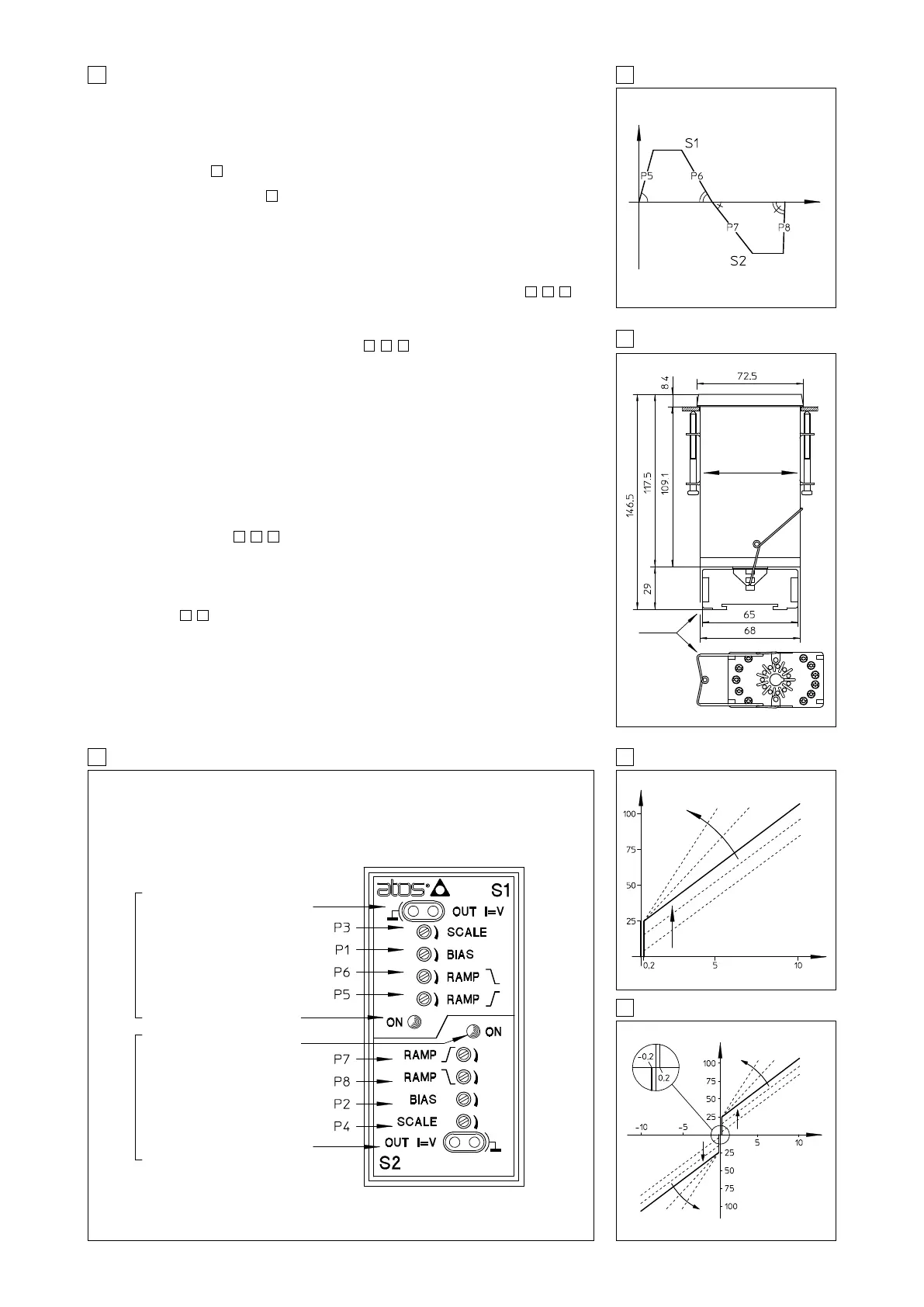

9 E-BM-AC-05F TOPOGRAPHICAL VIEW OF REGULATIONS

7 RAMPS

10 E-BM-AC-01F and 011F ADJUSTMENT

11 E-BM-AC-05F ADJUSTMENT

Current monitor test point

(mV read - mA)

Scale adjustment

Bias

Deceleration ramp (*)

Acceleration ramp

S1 channel enabled led

S2 channel enabled led

Acceleration ramp

Deceleration ramp (*)

Bias

Scale adjustment

Current monitor test point

(mV read - mA)

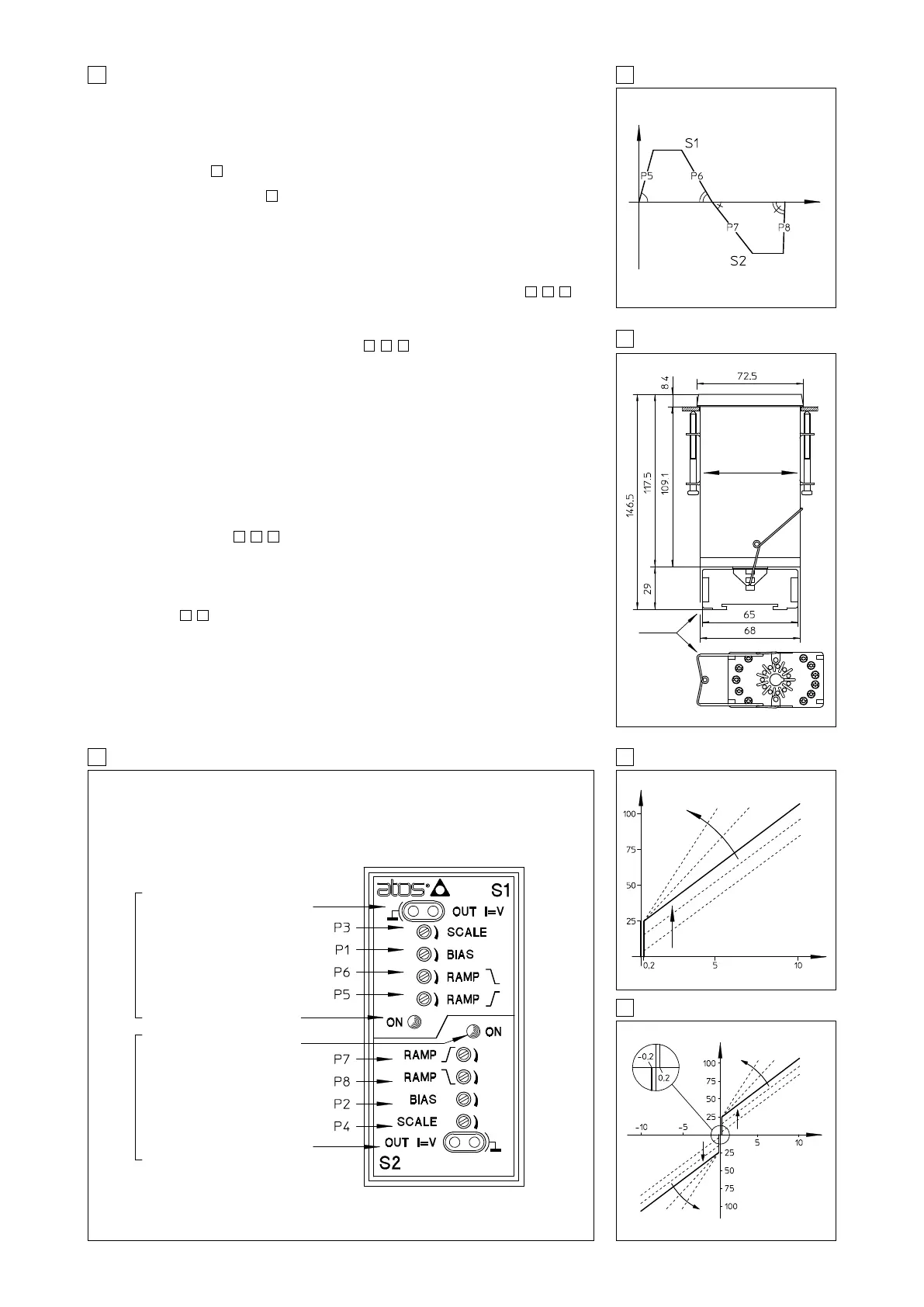

8 DIMENSIONS (mm)

UP AND DOWN

DISSYMETRICAL

RAMP GENERATOR

E-K-11B UNDECAL

SOCKET FOR

GUIDE DIN EN

50022-50035

MOUNTING

BOLTS FOR PANEL

FASTENING

[%] Current

BIAS ADJUSTMENT

P1, P2

SCALE ADJUSTMENT

P3, P4

Reference [V]

BIAS ADJUSTMENT

P1

[%] Current

SCALE

ADJUSTMENT P3

SCALE

ADJUSTMENT P4

Valve opening

Time

BIAS ADJUSTMENT

P2

S1

S2

S1, S2

E-K-11B

Reference [V]

SOLENOID S2 SOLENOID S1

(*) only for option /RR

Loading...

Loading...