DSP boarD rePlacement

4 Field Service Bulletin

Install the new DSP board

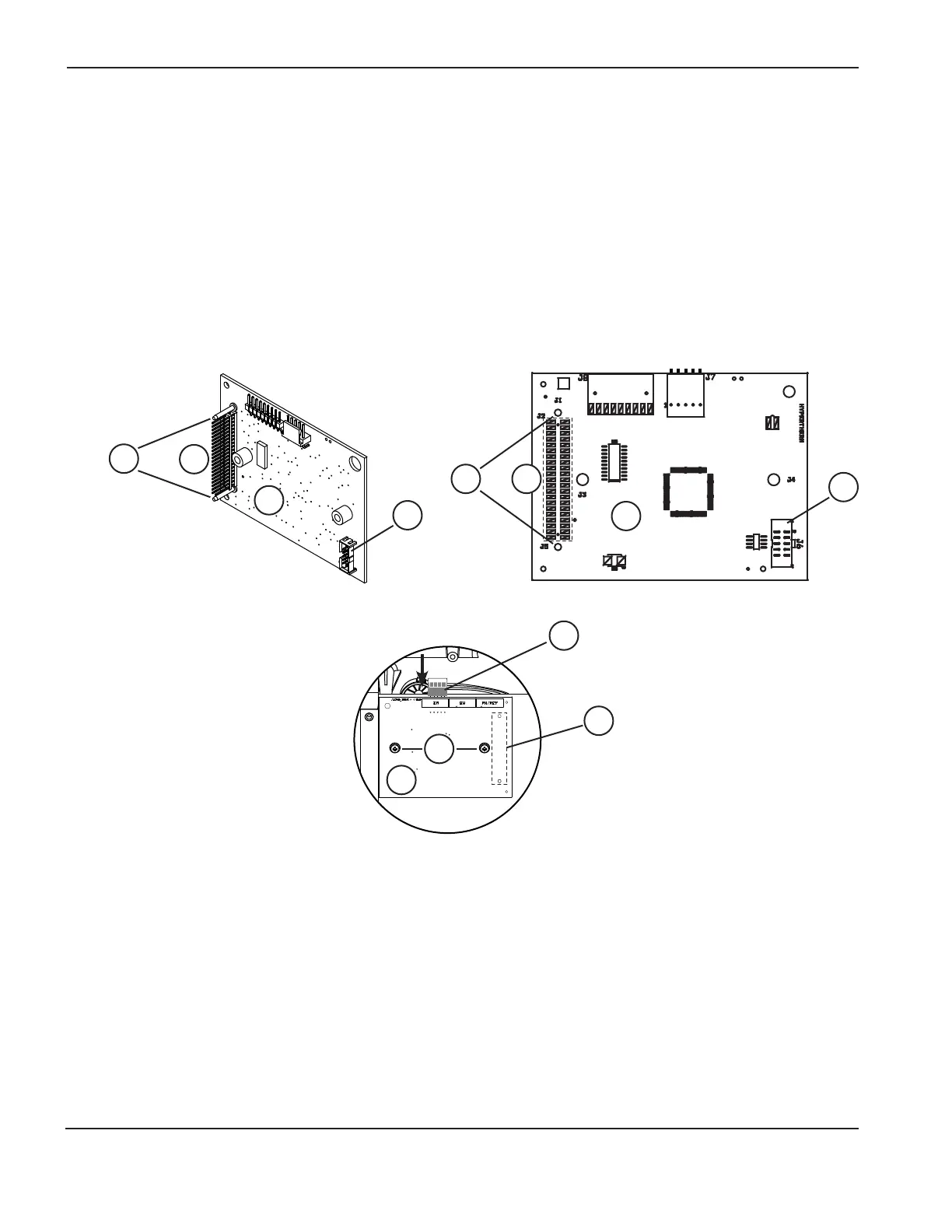

1. Connect the ribbon cable to the ribbon cable connector (6) on the back of the new DSP board (3).

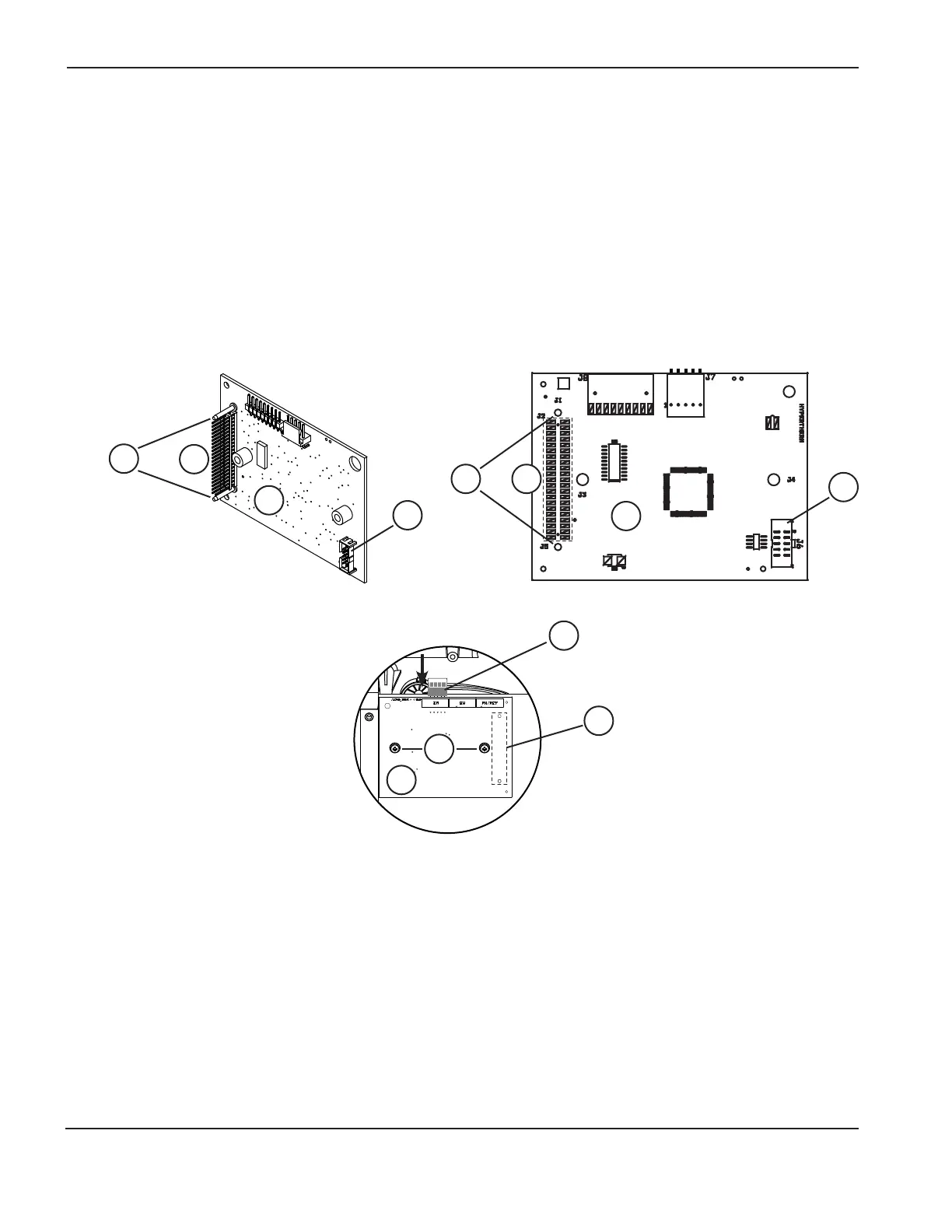

2. Align the two alignment pins (7) with the corresponding holes on the power board.

3. Carefully push the DSP board straight onto the power board. Do not bend the pins (4).

4. Use a #2 Phillips screwdriver to secure the DSP board to the power board using the 2 screws (2).

5. Connect the DSP connector (1) to the top of the DSP board if there is an RS485 communication board installed.

4

4

7

7

6

6

3

3

DSP back view

1

4

2

3

DSP front view

Loading...

Loading...