DSP boarD rePlacement

Field Service Bulletin 5

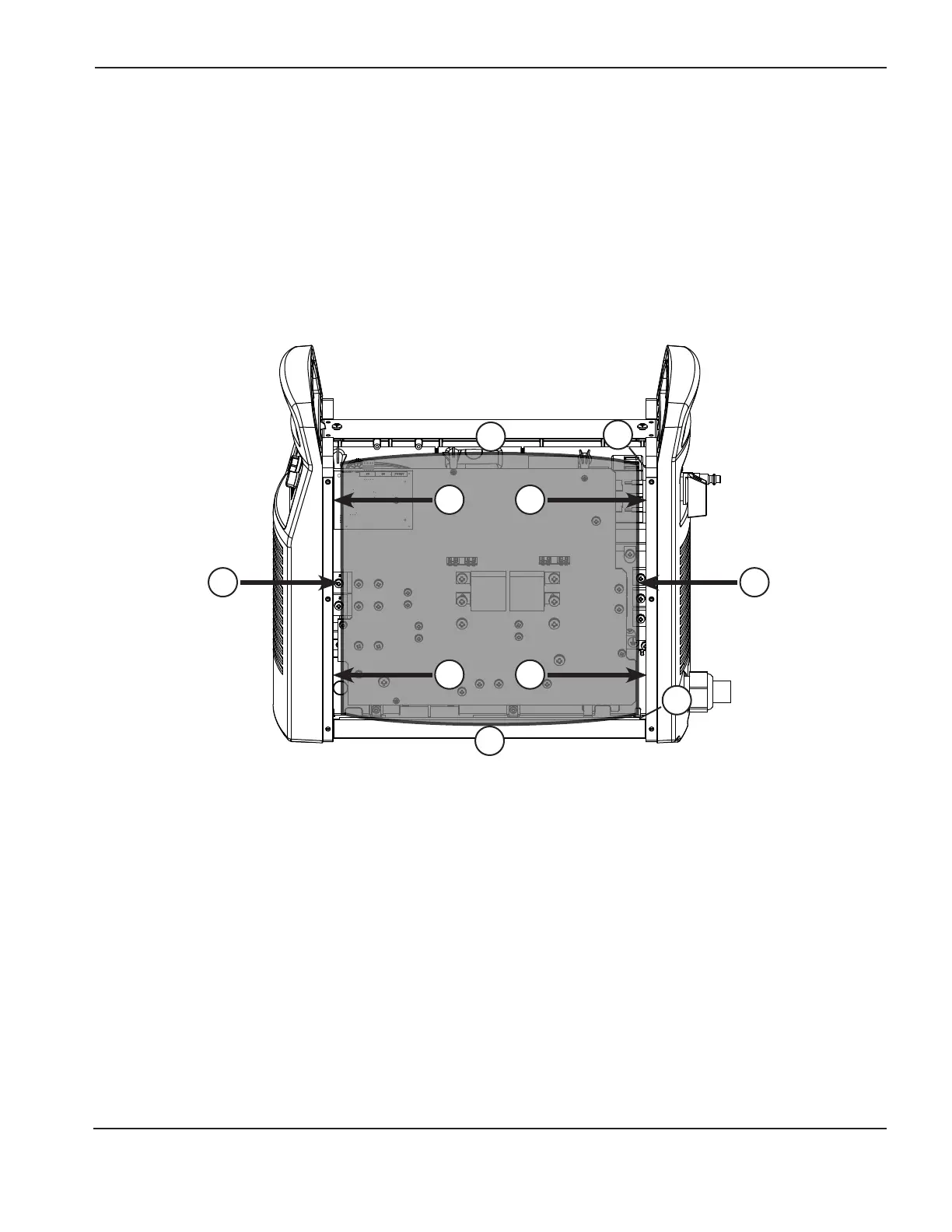

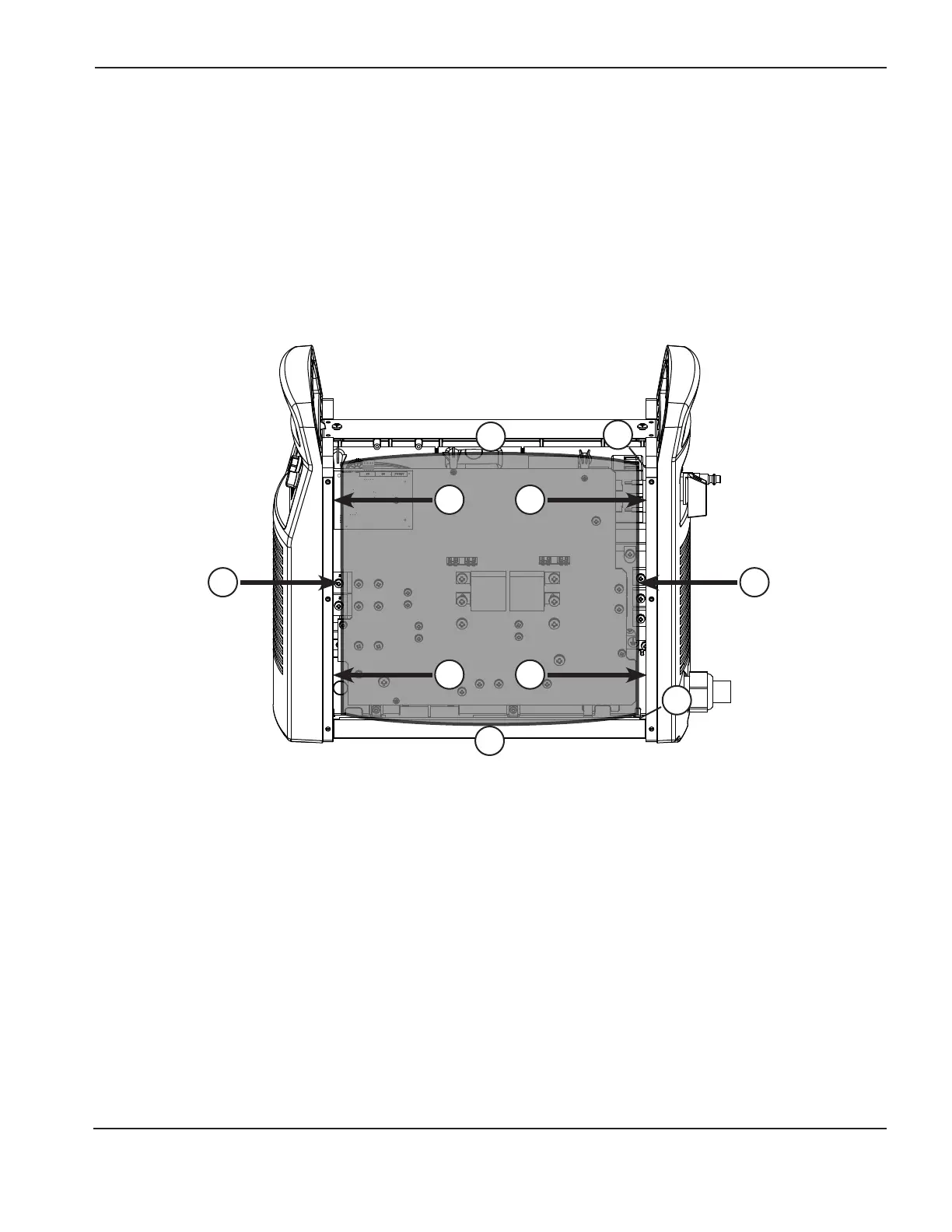

Replace the Mylar barrier

1. Carefully push in the sides (1) of the Mylar barrier so that the barrier bends out slightly at the top and bottom (2).

2. Slide the sides of the Mylar barrier behind the power supply frame (3). Be careful to get the barrier between the

frame and the power wires on the right side of the power board (4).

3. Gently bend the top of the barrier at the perforation so that the top bends over the top of the power supply.

4. Slide the barrier down so that the bottom edge fits inside the power supply frame (5).

1 1

3

3

3

4

5

3

2

2

Loading...

Loading...