8

Identify common system problems

Many common problems with Powermax

®

systems can

be solved by doing the following checks. For a more

complete list of problems like these, refer to Start here:

troubleshooting checklist in the Operator Manual.

• Examine the cartridge:

• Is the cartridge installed correctly?

• Is the cartridge worn or damaged?

• Examine the gas supply line:

• Are there any signs of contamination from oil,

water, or dirt? It is extremely important to keep

a clean, dry gas line.

• Are there any signs of leaks?

• Are any of the hoses twisted or kinked?

• Are you able to keep sufficient gas pressure

while cutting? Do a gas test if needed. Refer

to Do a gas test in the Operator Manual.

• Examine the power cord:

• Are the power cord wires connected correctly

and fully tightened in the plasma power supply

and in the power plug or line-disconnect box?

• Is the ground wire connected correctly?

• Is the power plug correct for the power cord?

• Examine the work lead and work clamp:

• Is the work lead connected correctly to the

plasma power supply?

• Is the work clamp connected to the workpiece

that you are cutting? Does it have good

metal-to-metal contact?

• Examine the torch and torch lead:

• Is the torch lead twisted or kinked?

• Is the O-ring on the torch head dry, cracked,

or damaged?

• Is the mechanized cutting system correctly grounded and

shielded? For best practices, refer to the Mechanized

Cutting Guide.

• If you see a fault code and fault icon on the LCD screen,

refer to Fault codes in the Operator Manual for more

information.

In some conditions, restarting the plasma

power supply can remove a fault condition.

© 2/2021 Hypertherm, Inc. 810510MU Revision 1

English

Identify probelms with cut quality

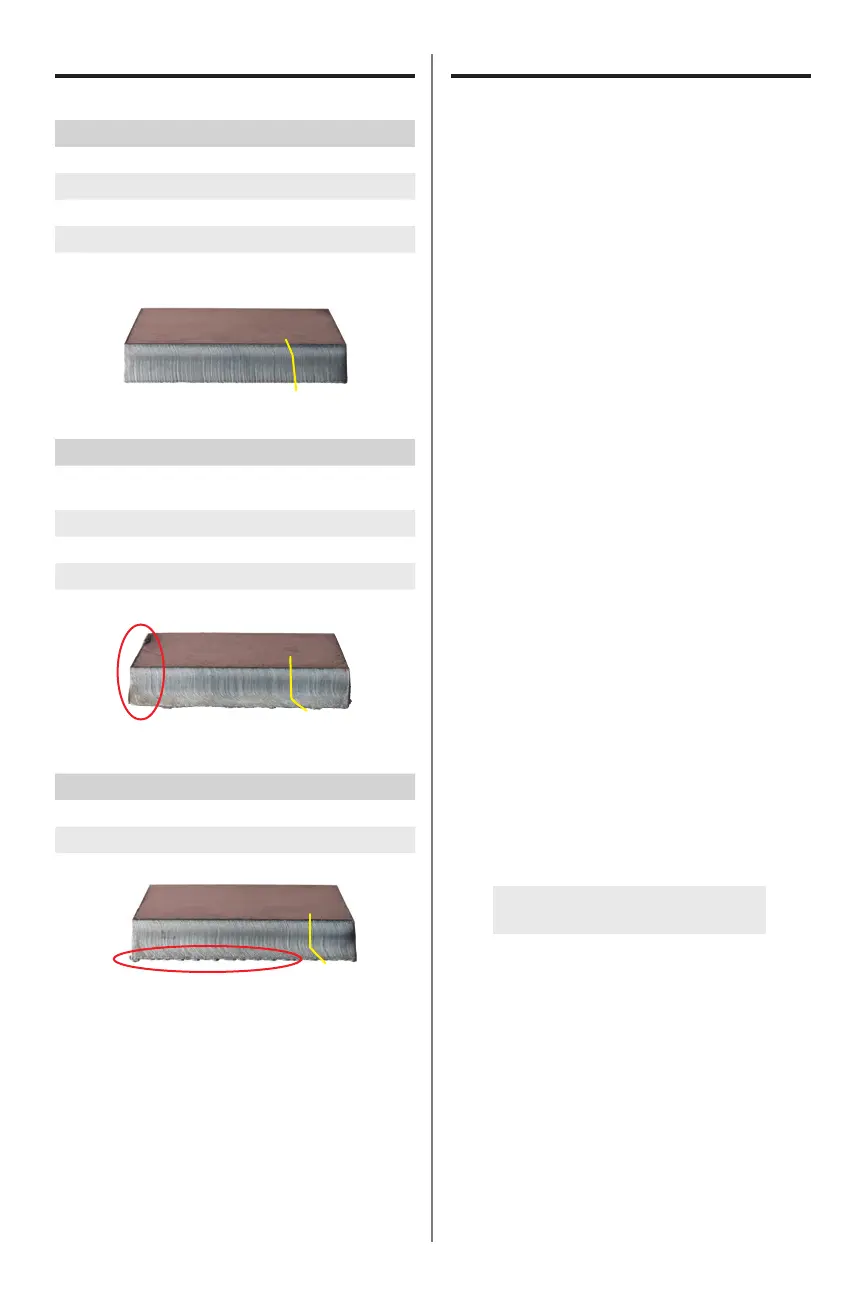

Optimal cut quality

What to look for

• Easy-to-see lag lines with an angle of 10°–15°

• Minimal dross

• Square edges

• No top splatter

• No discoloration

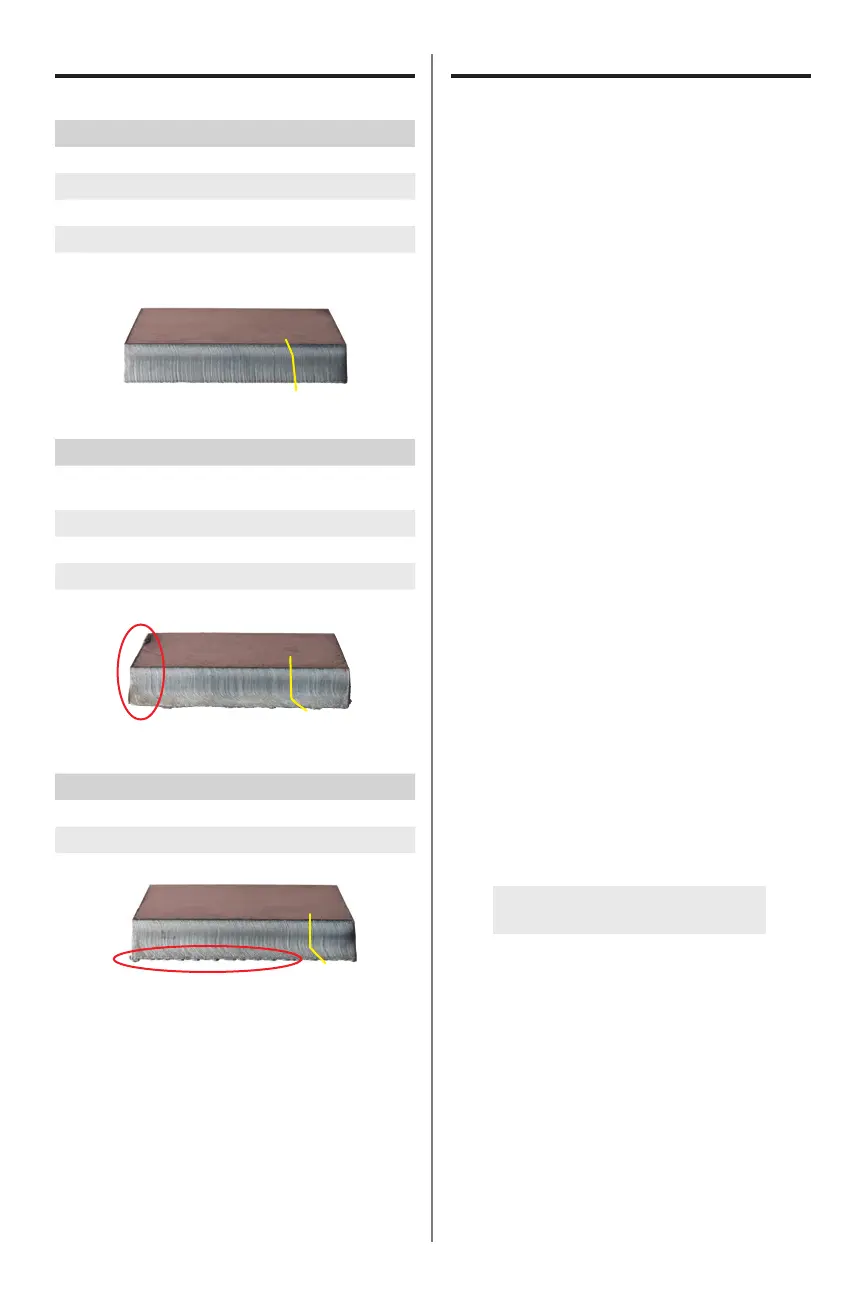

Too much of a bevel angle

Possible cause Solution

Torch is not at a 90° angle to the

workpiece

Align the torch at a 90° angle to the

workpiece

Amperage is too low Increase the amperage

Speed is too fast Decrease the speed

Worn cartridge Install a new cartridge

Hardened dross

Possible cause Solution

Speed is too fast Decrease the speed

Amperage is too low Increase the amperage

Loading...

Loading...