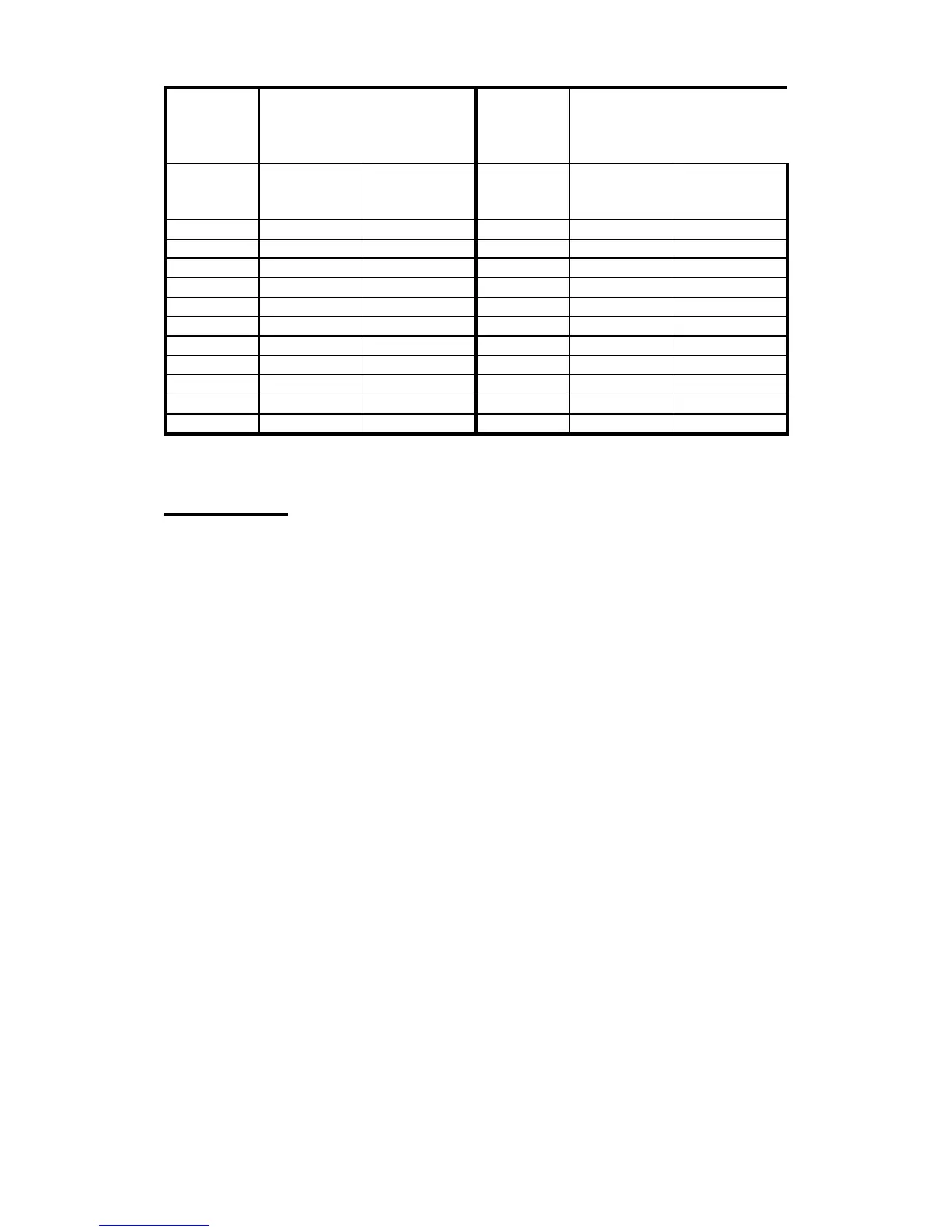

10 11

72 7,20 6,55 83 8,30 7,55

73 7,30 6,64 84 8,40 7,64

74 7,40 6,73 85 8,50 7,73

75 7,50 6,82 86 8,60 7,82

76 7,60 6,91 87 8,70 7,91

77 7,70 7,00 88 8,80 8,00

78 7,80 7,09 89 8,90 8,09

79 7,90 7,18 90 9,00 8,18

80 8,00 7,27 91 9,10 8,27

81 8,10 7,36 92 9,20 8,36

82 8,20 7,45

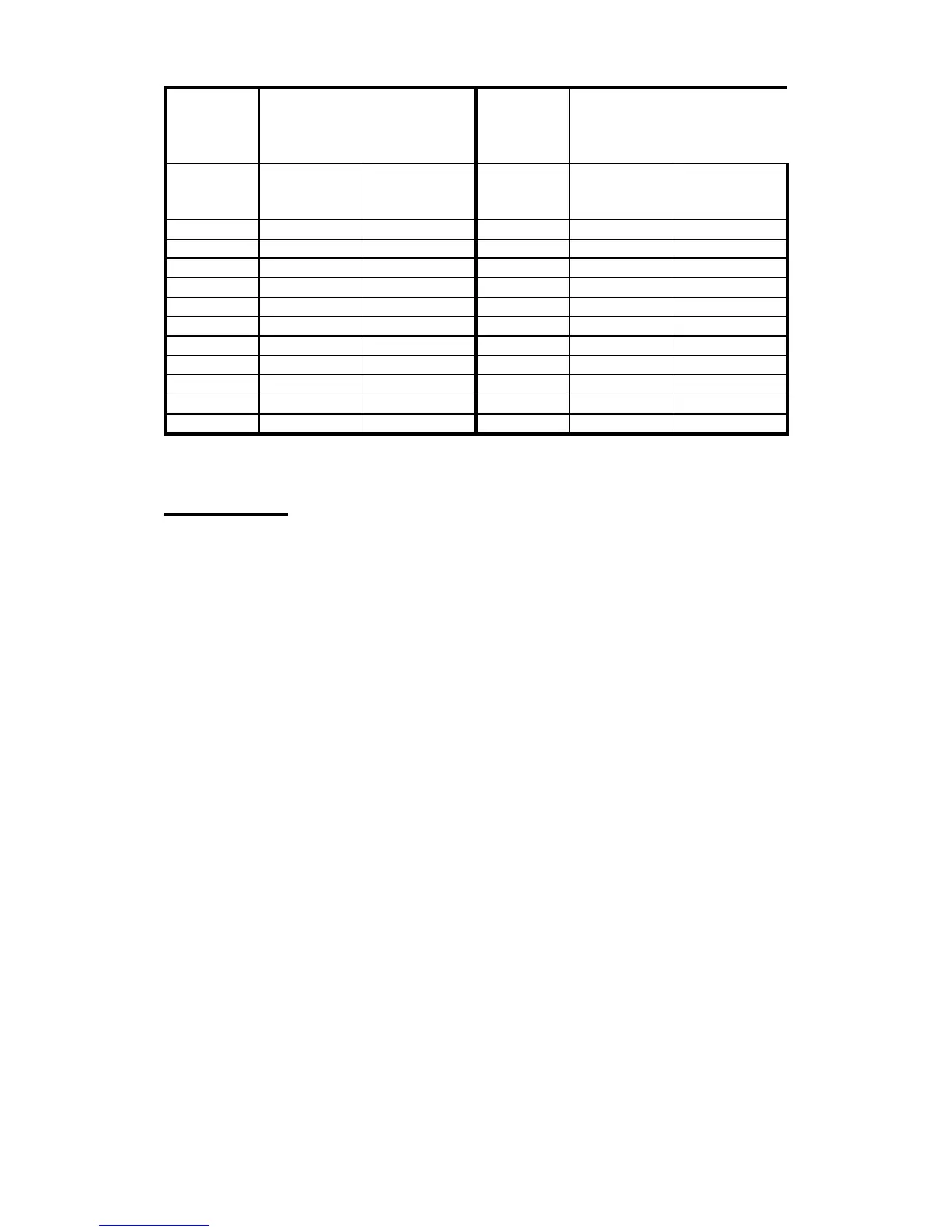

For the operation limit of 15000 RPM the following table (Tab.2) has been prepared.

SUGGESTION:

?? During the track tests we recommend use of a tachometer recording the

max obtained engine RPM.

?? Use sparkplug caps with a resistance of 5KO to avoid eventual

interferences between the engine ignition and the tachometer and/or

telemetry.

The following example should clarify the procedure for the optimization of the

sprocket .

Assume to use the engine with Z=10 teeth engine sprocket and that during the

preliminary track tests a Z=72 teeth axle sprocket has been used.

?? From table 1 with Z=10 as engine sprocket and Z=72 on the axle sprocket, a ratio

of 7.20 is found.

?? Make a few laps on the track and, let us assume that you read 14.000 max

engine RPM.

?? From the table 2 to achieve a max RPM of 15000 RPM (operating limit for the

Leopard engine) a sprocket ratio from 7.61 and 7.82 should be used (having

used, during the tests, a sprocket ratio of 7.2 and having achieved 14.000 RPM

max.).

?? From table.1 , with these values, a sprocket ratio of 10:76 / 10:78 should be used

or, having a Z=11 on the engine sprocket, a ratio 11:85 should be used.

Tab.1

Loading...

Loading...