21

MAN-028

NOTE: (L) may need to be fine tuned again after a jet change. If so proceed as

above.

PROCEDURE FOR CHANGING FIXED SIDE JET

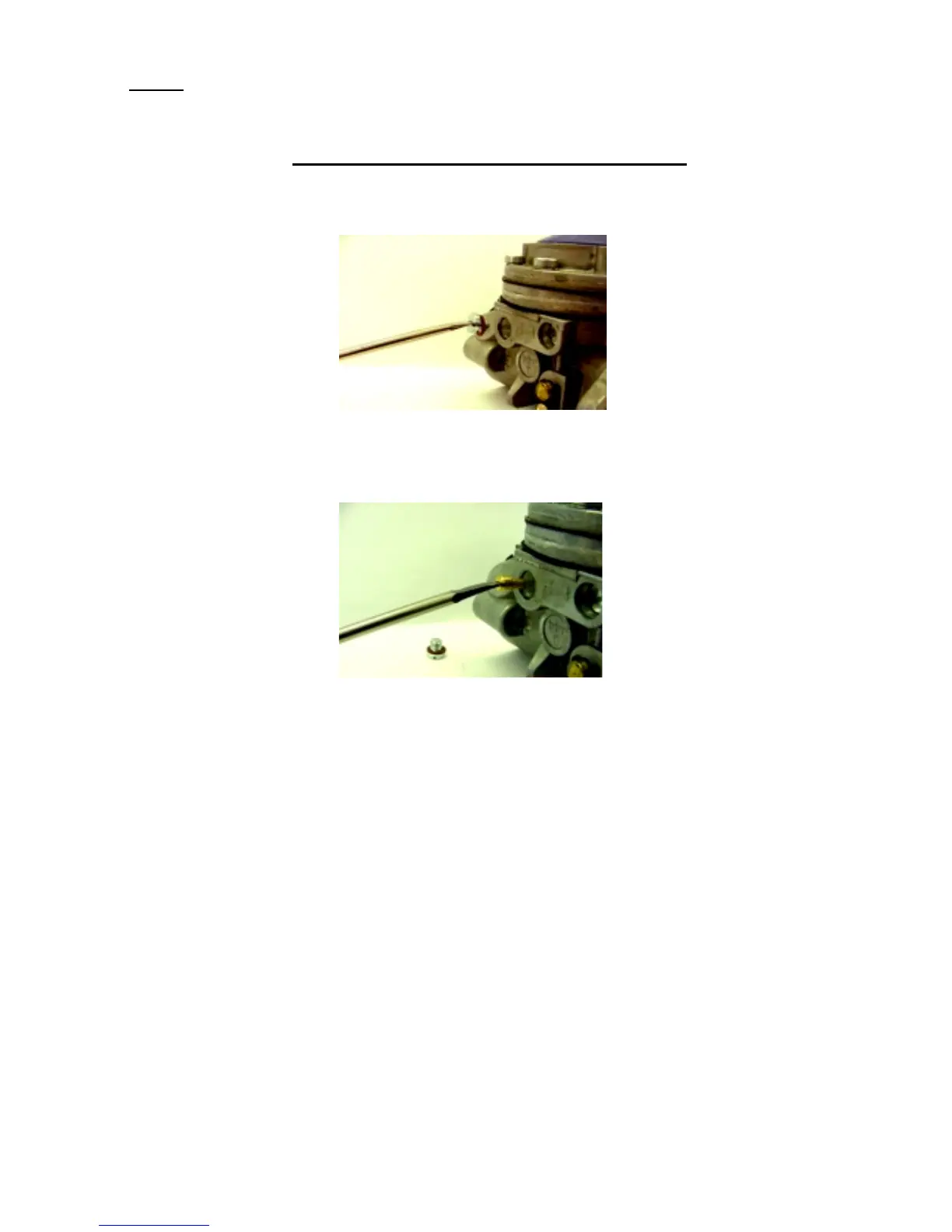

1. Remove sealing screw and gasket using a flat ended screwdriver turning anti-clockwise

(see fig.1)

Fig. 1

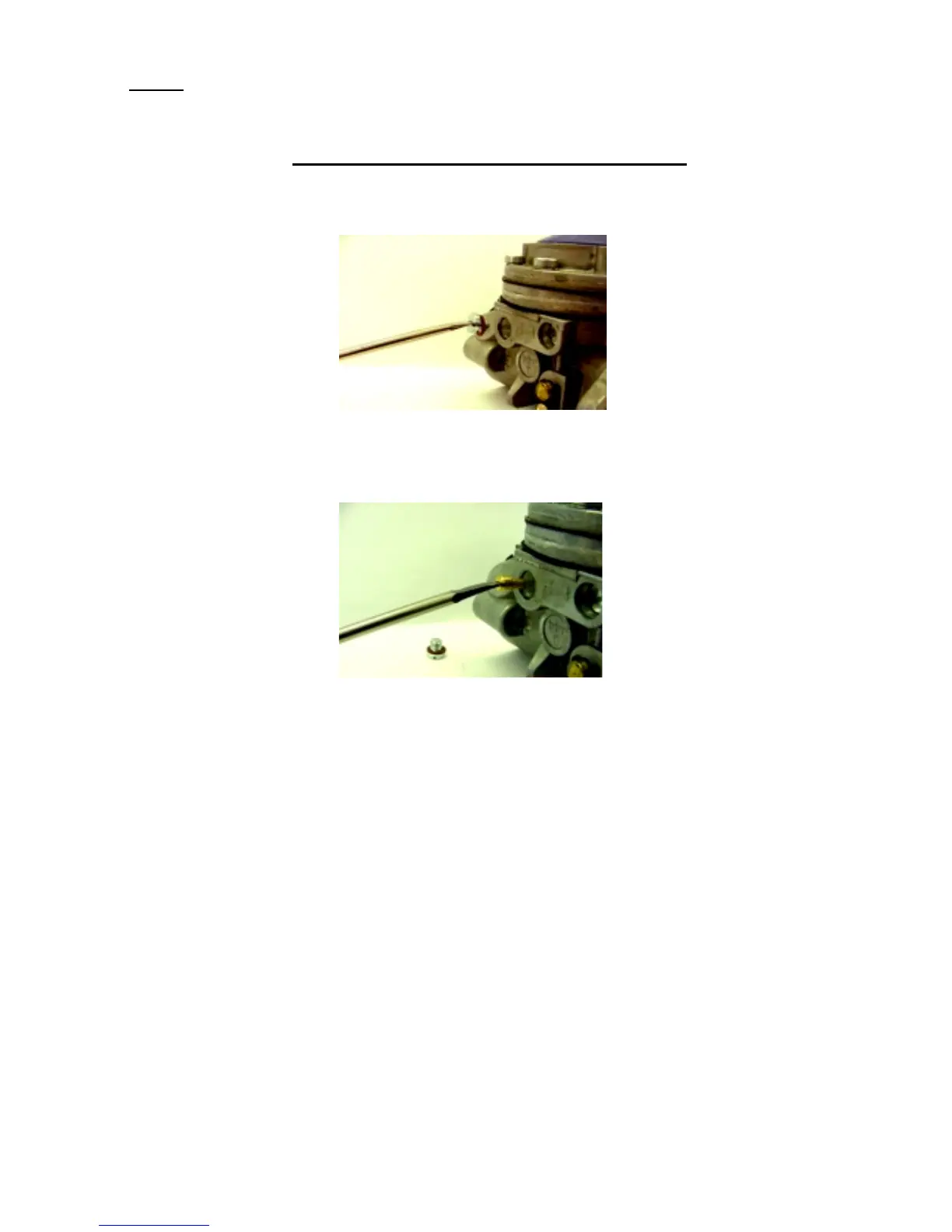

2. Remove fixed jet using a 3mm flat ended screwdriver turning anti-clockwise. Ensure

the screwdriver is securely located in jet slot before turning as slot is easily damaged

(see fig.2)

Fig. 2

3. When replacing jet place jet in threaded orifice and carefully turn clockwise until

threads are engaged. Using a light hand pressure screw jet in fully until it touches the

sealing seat. Then secure jet using a medium hand pressure (5 Lb/In or 0.565 Nm if

using a torque screw driver). Over torqueing will distort sealing seat and brass jet.

4. Replace sealing screw and gasket turning in a clockwise direction again using only a

medium hand pressure to secure in position (8 Lb/In or 0.904 Nm if using a torque

screwdriver). There is only 4÷5 full threads of engagement so over torqueing will cut

the threads and render the carburetor unserviceable.

Loading...

Loading...