SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MVE

Specifications subject to change without notice.

22 440 04 4801 03

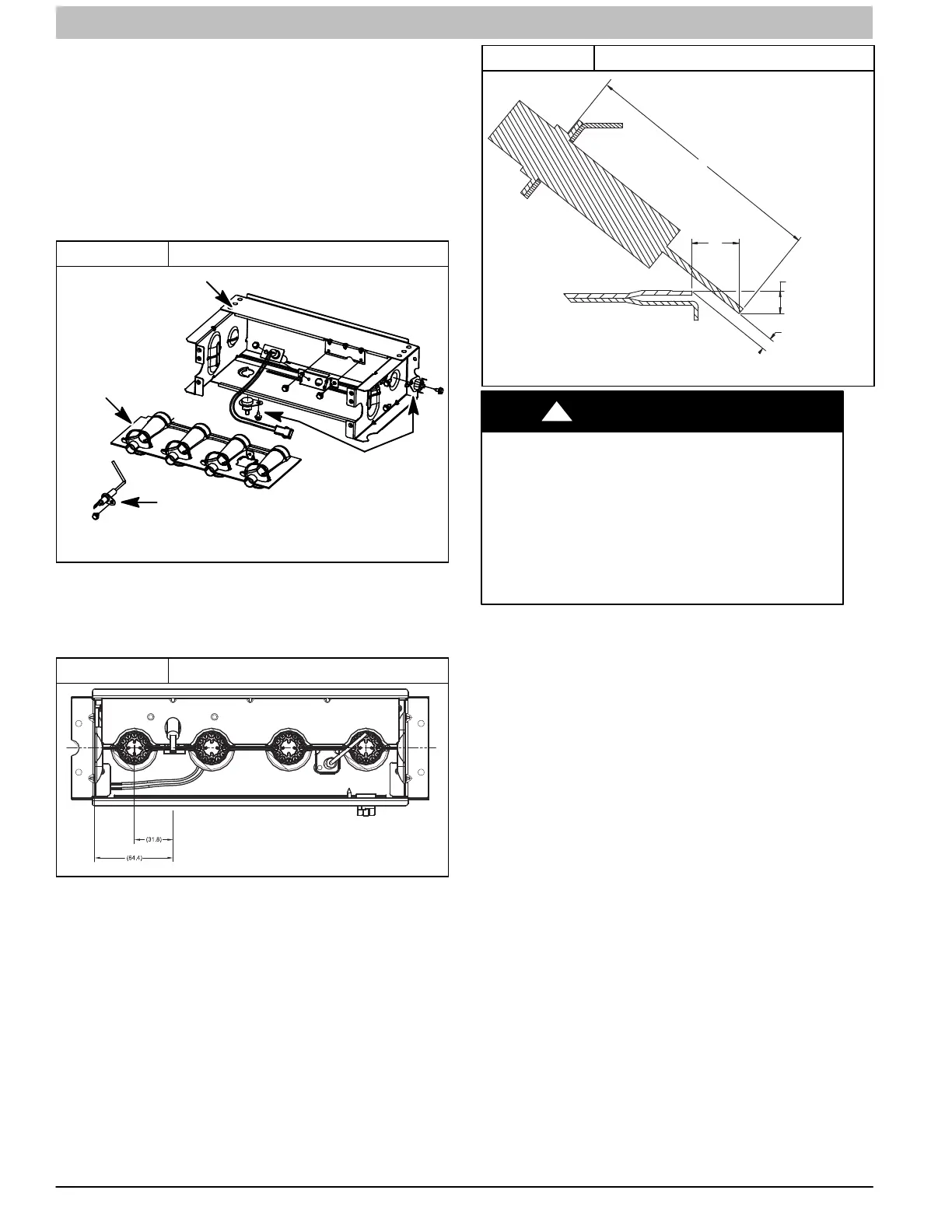

3. Align the edges of the one-piece burner with the slots in

the burner assembly and slide the burners forward until

they are fully seated in the burner assembly.

4. Align the orifices in the manifold assembly with the

support rings on the end of the burner.

5. Insert the orifices in the support rings of the burners.

NOTE: If manifold does not fit flush against the burner, do not

force the manifold on the burner assembly. The burners are not

fully seated forward in the burner assembly. Remove the

manifold and check burner positioning in the burner assembly

assembly before re-installing the manifold.

Figure 10 Burner Assembly

BURNER ASSY

FLAME SENSOR

(

BELOW BURNER)

FLAME ROLL−OUT SWITCH

BURNER SUPT. ASSY

L11F064

Representative drawing only, some models may vary in appearance.

6. Attach the green/yellow wire and ground terminal to one

of the manifold mounting screws.

7. Install the remaining manifold mounting screws.

8. Check the igniter alignment. See Figure 10, Figure 11

and Figure 12.

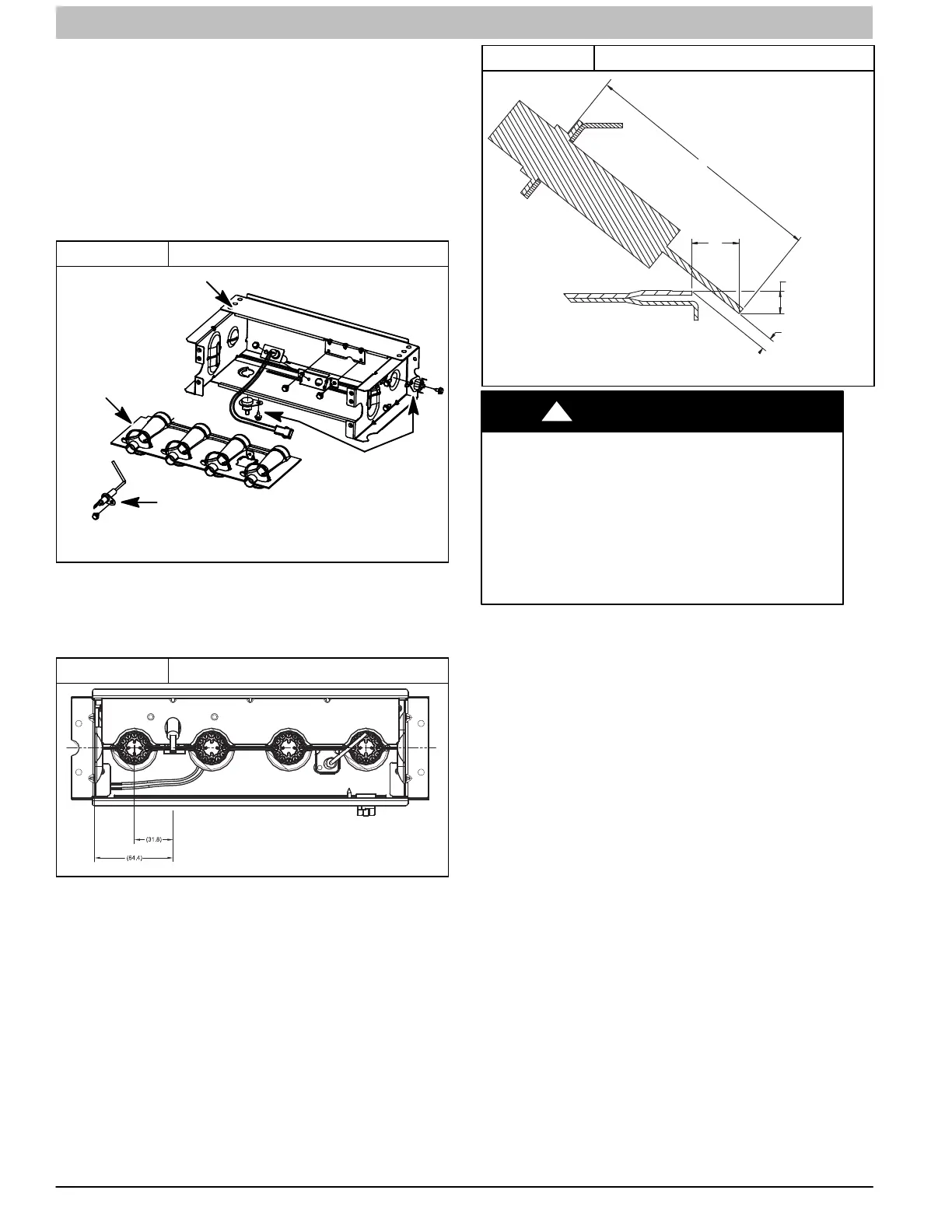

Figure 11 Igniter Position − Top View

A11271

1-1/4-in.

2-1/2-in.

9. Attach the wires to the roll-out switches.

10. Align the burner assembly with the openings in the

primary cell inlet panel and attach the burner assembly to

the cell panel.

11. Connect the wire for the flame sensor.

12. Connect the wire for the Hot Surface Igniter.

NOTE: Use propane-resistant pipe dope to prevent leaks. Do

not use Teflon tape.

13. Install the gas pipe to the gas valve.

Figure 12 Igniter Position − Side View

L12F041

2ïin.

2.5 mm

3/8ïin.

3/16ïin.

+0.8

ï1.5 mm

50 mm

9.6 mm

4.6 mm

1/10ïin.

+ 1/32

ï 1/16ïin.

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Never purge a gas line into a combustion chamber.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made

specifically for the detection of leaks to check all

connections. A fire or explosion may result causing

property damage, personal injury or loss of life.

!

WARNING

14. Check for gas leaks with a commercially available soap

solution made specifically for the detection of leaks.

15. Turn gas on at electric switch on gas valve and at

external shut-off or meter

16. Turn power on at external disconnect, fuse or circuit

breaker.

17. Run the furnace through two complete heating cycles to

check for proper operation

18. Install control door when complete.

Servicing Hot Surface Igniter

The igniter does NOT require annual inspection. Check igniter

resistance before removal. Refer to Figure 10, Figure 11 and

Figure 12.

1. Turn off gas and electrical supplies to furnace.

2. Remove control door.

3. Disconnect igniter wire connection.

4. Check igniter resistance. Igniter resistance is affected by

temperature. Only check resistance when the igniter is at

room temperature.

a. Using an ohm meter, check resistance across both

igniter leads in connector.

b. Cold reading should be between 40 ohms and 70

ohms.

Loading...

Loading...