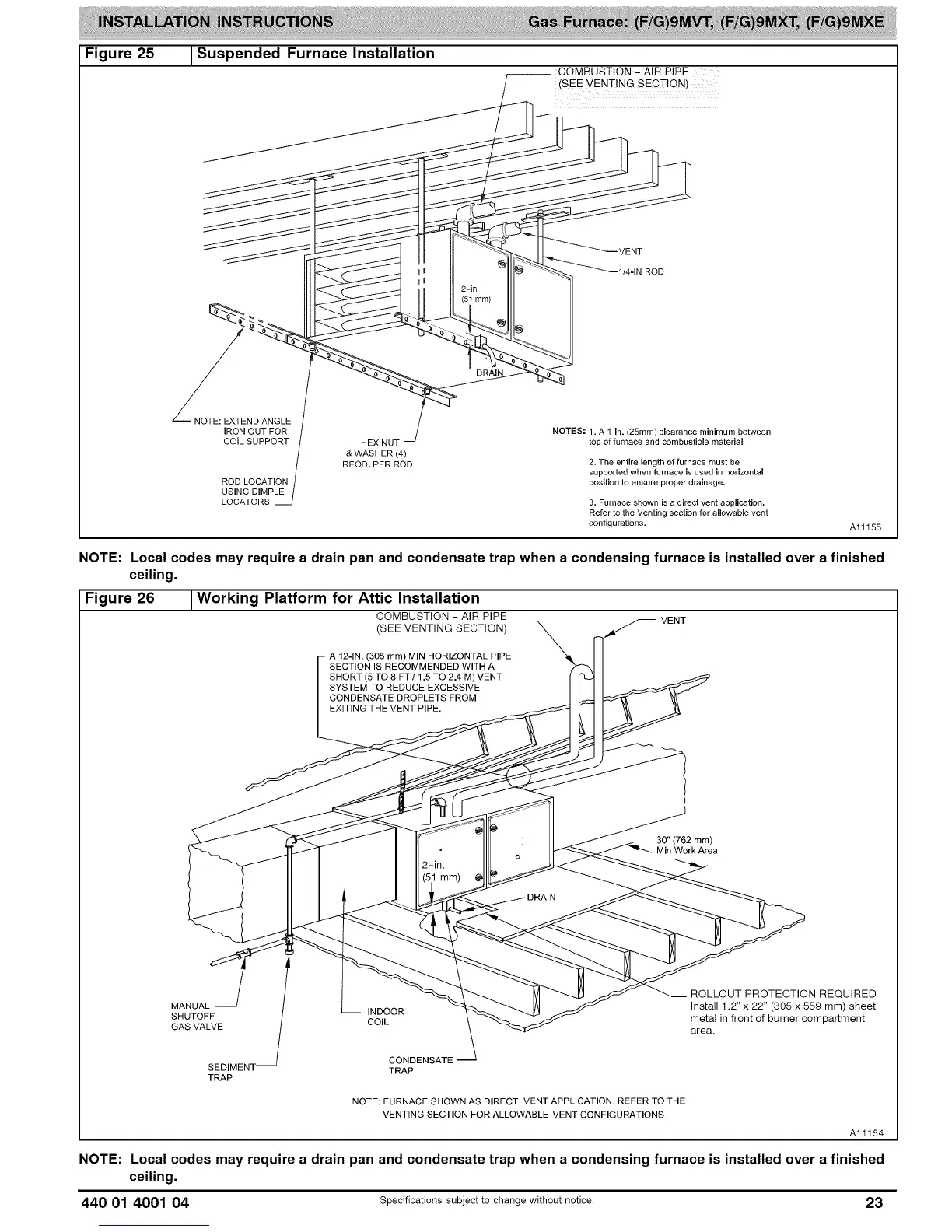

Figure 25 _Suspended Furnace Installation

(SEE VENTING SECTION)

VENT

NOTE: EXTEND ANGLE

IRON OUT FOR

COIL SUPPORT

ROD LOCATION

USING DIMPLE

LOCATORS

HEX NUT

& WASHER (4)

REQD, PER ROD

NOTES: 1. A 1 In. (25ram) clearance minimum between

top of furnace and combustible material

2. The entire length of furnace must be

supported when furnace is used in horizontal

position to ensure proper drainage.

3. Furnace shown is a direct vent application.

Refer to the Venting section for allowabme vent

configurations.

Al1155

NOTE: Local codes may require a drain pan and condensate trap when a condensing furnace is installed over a finished

ceiling.

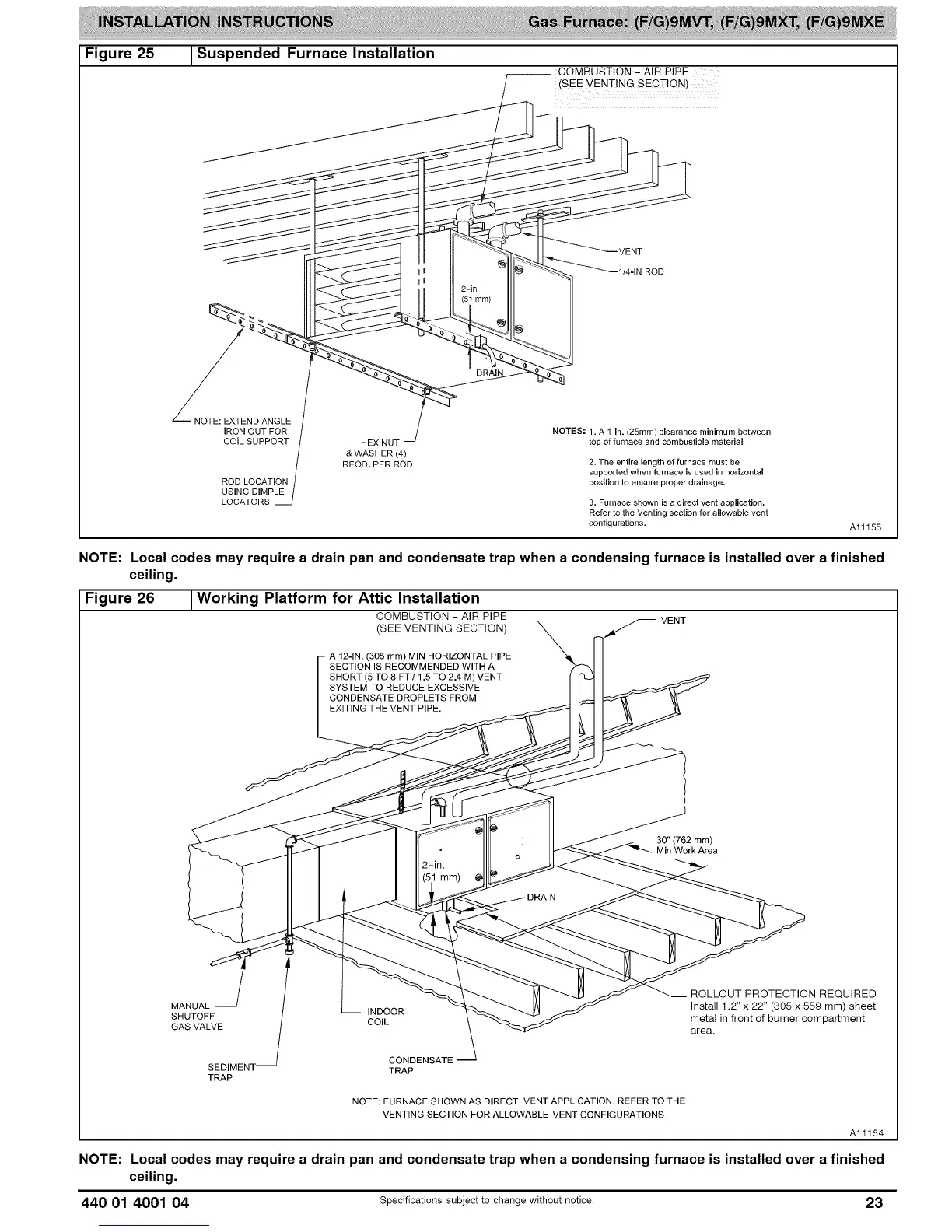

Figure 26

IWorking Platform for Attic Installation

COMBUSTION - AIR PIPE

(SEE VENTING SECTION)

VENT

A 12-1N, (305 ram) MIN HORIZONTAL PIPE

SECTION IS RECOMMENDED WITH A

SHORT (5 TO 8 FT / 1,5 TO 2,4 M) VENT

SYSTEM TO REDUCE EXCESSIVE

CONDENSATE DROPLETS FROM

EXITING THE VENT PIPE,

30" (762 mm)

Min Work Area

MANUAL

SHUTOFF

GAS VALVE

INDOOR

COIL

ROLLOUT PROTECTION REQUIRED

Install 1.2" x 22" (305 x 559 ram) sheet

metal in front of burner compartment

area.

SEDI

TRAP

CONDENSATE

TRAP

NOTE: FURNACE SHOWN AS DIRECT VENT APPLICATION. REFER TO THE

VENTING SECTION FOR ALLOWABLE VENT CONFIGURATIONS

Al1154

NOTE: Local codes may require a drain pan and condensate trap when a condensing furnace is installed over a finished

ceiling.

440 01 4001 04 Specifications subject to change without notice. 23

Loading...

Loading...