64

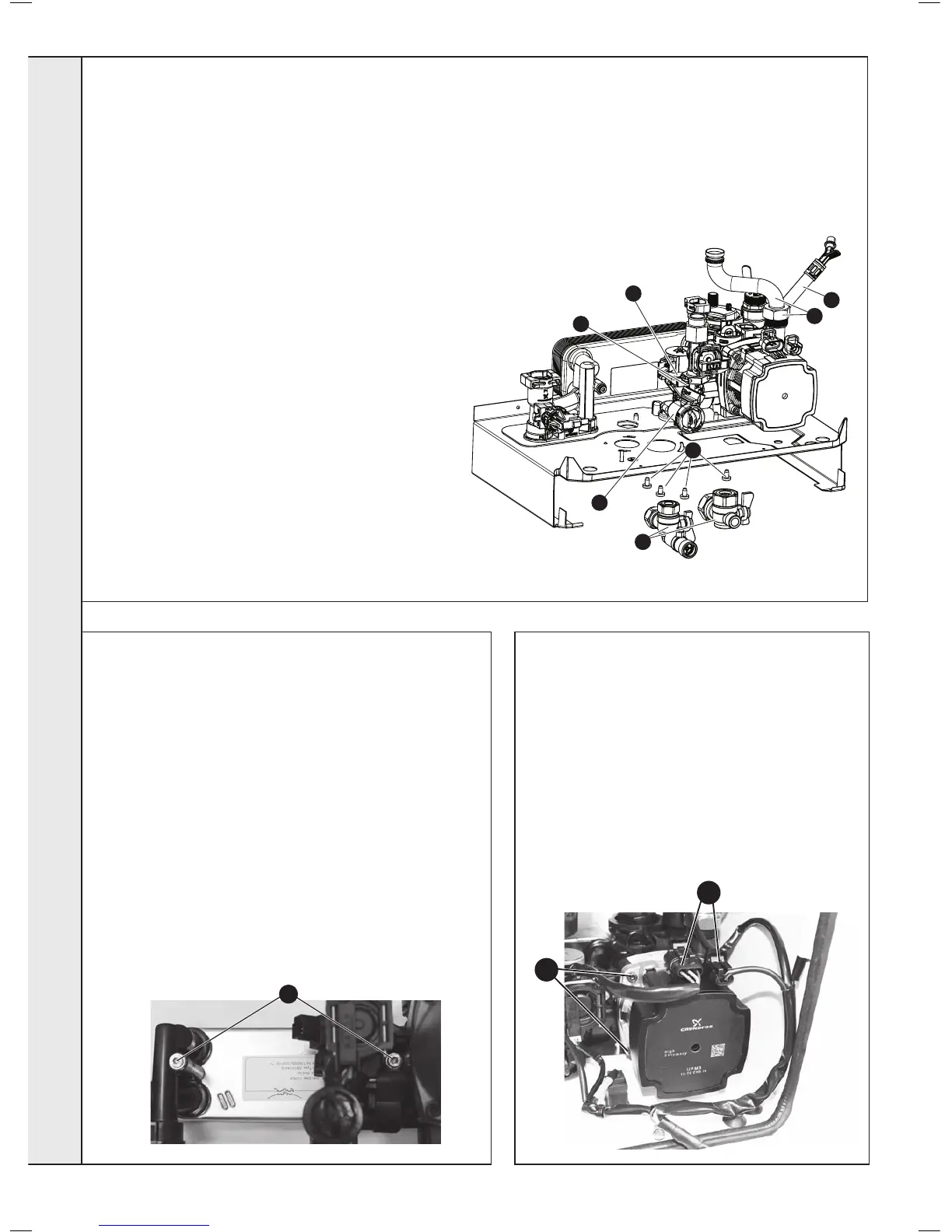

To remove the valve body assembly:

1. Refer to Frame 45.

2. Drain the boiler. Refer to frame 59.

3. Remove the condensate trap/siphon. Refer to Frame 55.

4. Remove the electrical plug. Refer to Frame 54.

5.

Place a at bladed screwdriver in the diverter valve motor

body slot provided and ease out the motor Refer to Frame 54.

6. Remove the return thermistor electrical connection. Refer to

Frame 49.

7.

Remove the pump electrical connection. Refer to Frame 66 no. 3.

8.

Remove DHW Turbine electrical connection. Refer to Frame 58 no. 3.

9. Remove the DHW plate heat exchanger (note orientation).

Refer to Frame 65.

10.

Undo the safety valve pipe compression tting. See No.5 Frame 61.

11. Loosen the nut above pump and rotate the pipe.

12. If required remove expansion vessel connection hose.

Refer to Frame 71.

13. Remove the DHW inlet and CH return connection situated

beneath the boiler.

14. Remove the three torx head screws xing the return

manifold to the boiler sheet steel base.

15. Lift the manifold assembly and remove from boiler.

16. Twist and remove the DHW manifold.

17. Remove the two diverter valve body xing screws and

withdraw the diverter valve body assembly.

18. Fit the new diverter valve body assemble and replace the

two xing screws.

19. Ret the DHW manifold, t the assembly back to the boiler

and reassemble in reverse order.

20. Rell the boiler. Check operation of the boiler. Refer to

Frames 32-36.

14

11

12

13

16

18

17

1. Refer to Frame 45.

2. Drain the boiler. Refer to Frame 59.

3. Remove condensate trap/siphon. Refer to Frame 55.

4. Remove the diverter valve actuator. Refer to Frame 54.

5. Remove the 2 allen screws securing the plate heat exchanger

to the composite housings.

6. Manoeuvre the plate heat exchanger out of the top LH or

centre of the controls area. Be aware of any water spillage.

7. Fit the new plate heat exchanger, using the new o-rings

supplied.

Note. Ensure that the depressions are on the bottom prior to

tting.

8. Reassemble in reverse order.

9. Rell the boiler. Refer to Frame 24.

10. Check operation of the boiler. Refer to Frame 32-36.

65

DHW PLATE HEAT EXCH. REPLACEMENT

66

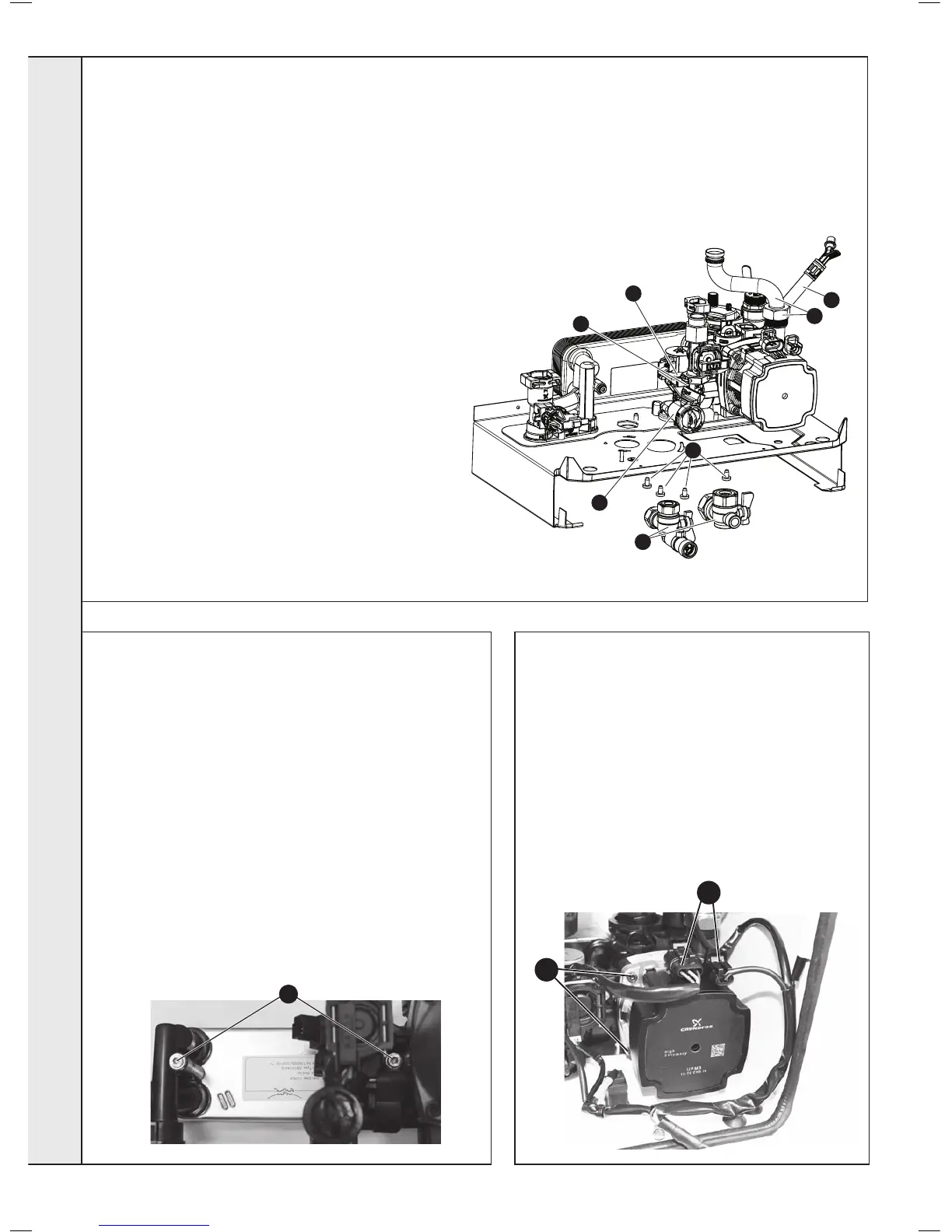

PUMP HEAD REPLACEMENT

1. Refer to Frame 45.

2. Drain the boiler. Refer to Frame 59.

3. Disconnect the two electrical leads from the pump.

4. Remove the 4 Allen screws retaining the pump head.

5. Remove the pump head.

6. Fit the new pump head.

7. Reassemble in reverse order.

8. Rell the boiler. Refer to Frame 24.

9.

Check operation of the boiler. Refer to Frames

32-36.

5

3

4

Loading...

Loading...