UK

CompactModul Metall CR2032

5

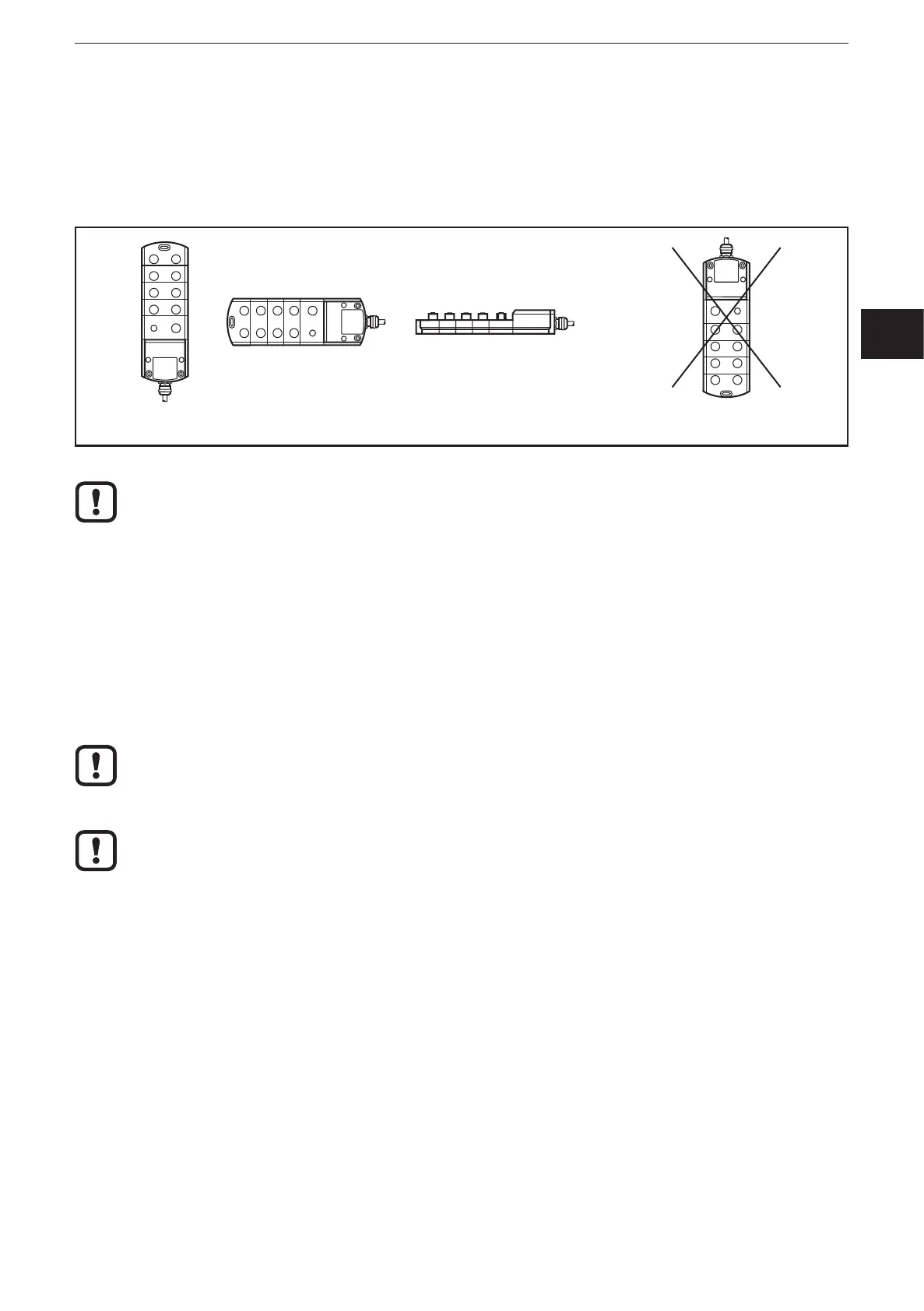

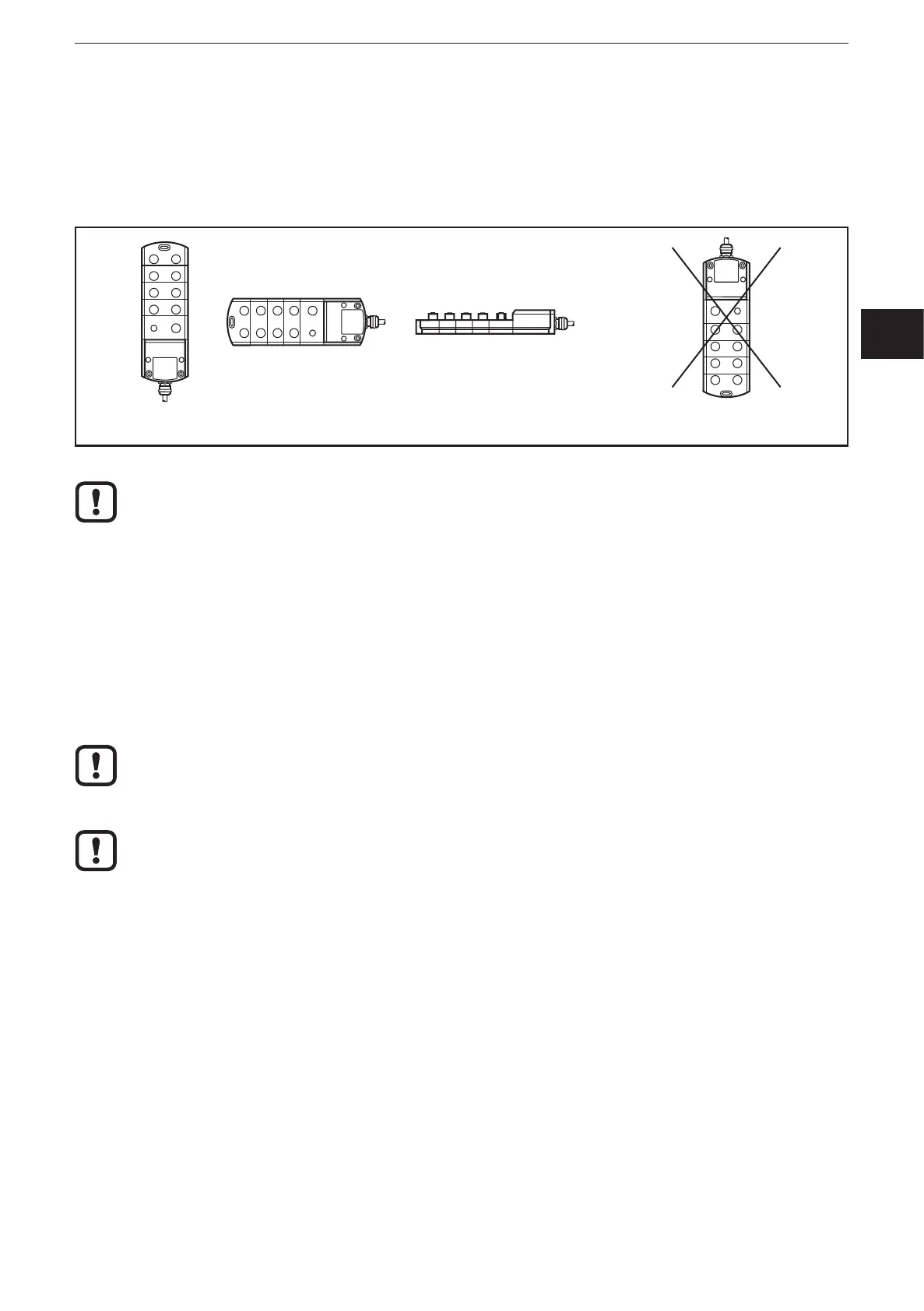

5 Mounting

To protect the module against mechanical stress it must be mounted so that it lies

completely flat on an even mounting surface� To do so, three cylinder screws with

hexagon socket (M5 x L) to DIN 912 or DIN 7984 must be used�

preferred Mounting variants wrong

To avoid contact corrosion between the mounting screws and the module

housing, do not use any stainless steel screws or nickel-plated screws!

In very corrosive environments such as extremely salty air, we recommend

to use screws with surface finishing on a zinc/nickel basis with thick-film

passivation and sealing� For normal corrosive requirements zinc-plated

screws are sufficient�

6 Electrical connection

To guarantee the electrical interference protection of the module, the hou-

sing must be connected to GND (e�g� to the ground of the vehicle)�

Due to the maximum operating temperature of 85 °C and the internal hea-

ting of the unit, the respective minimum rated temperature of the connection

cable must be taken into account�

6.1 M12 sockets

► Use sockets with gold-plated contacts�

► Use protective caps (supplied) for unconnected connectors of the I/O module�

6.2 Tightening torque of the cover screws (terminal chamber)

To close the terminal chamber the cover screws are tightened with a tightening

torque of 1�2 Nm�

6.3 M16 cable gland

Use a suitable cable to ensure ingress resistance of the M16 cable gland�

Loading...

Loading...