18

1-27

1-28

INSTALLERUSER

MAINTENANCE TECHNICIAN

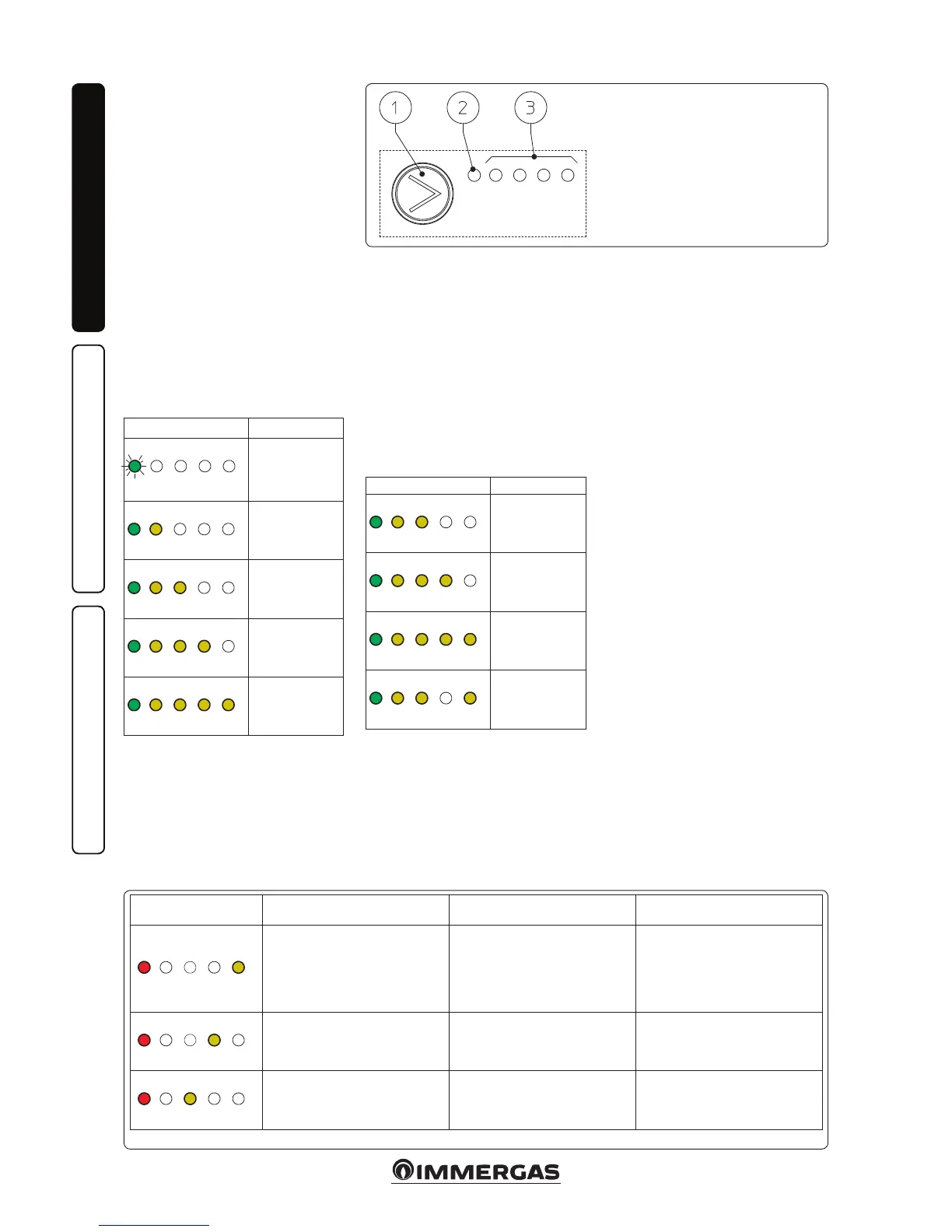

Key:

1 - Function selection button

2 - Green (G) / red (R) LED

3 - 4 yellow LEDs (Y)

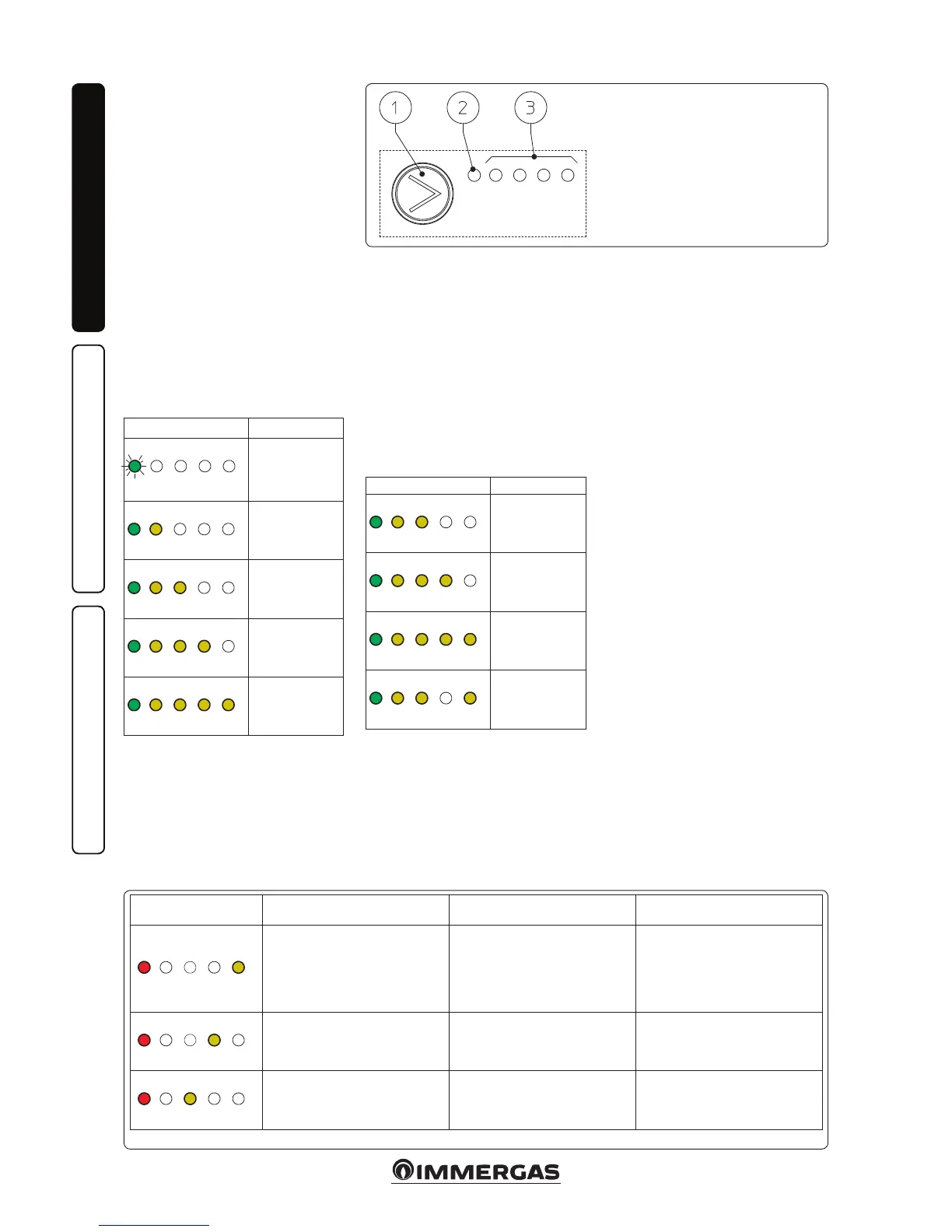

Circulating pump LED

(rst red LED)

Description Diagnostics Remedy

R Y Y Y Y

On O O O On

Circulator pump blocked

The circulator pump cannot restart

automatically due to an anomaly

Wait for the circulator to make auto-

matic release attempts or manually

release the motor sha acting on the

screw in the centre of the head.

If the anomaly persists replace the

circulator.

R Y Y Y Y

On O O On O

Abnormal situation (the circulator

continues operating).

low power supply voltage

Voltage o range Check power supply.

R Y Y Y Y

On O On O O

Electrical fault

(Circulator pump blocked)

e circulator is locked due to power

supply too low or serious malfunction

Check the power supply, if the anomaly

persists replace the circulator.

1.24 CIRCULATION PUMP.

e boiler is supplied with circulator tted with

speed regulator.

ese settings are suitable for most systems.

In fact, the pump is equipped with electronic

control to set advanced functions. For proper op-

eration one must select the most suitable type of

operation for the system and select a speed in the

available range, with a focus on energy savings.

By-pass Regulation (part. 29 Fig. 1-30). e

boiler is supplied with by-pass closed by 1.5 turns

with respect to all open.

If necessary, the by-pass can be regulated to

system requirements from minimum (by-pass

closed) to maximum (by-pass open). Adjust

using a at head screwdriver, turn clockwise to

close the by-pass; turn anti-clockwise to open it.

Display of operation status. During normal

operation, the status LED (2) is on green (ashing

(FL) when it is in stand-by), the four yellow LEDs

(3) indicate circulator absorption according to

the following table:

Circulating pump LED Absorption

G Y Y Y Y

FL O O O O

Circulator in

stand-by

G Y Y Y Y

On On O O O

0 ÷ 25 %

G Y Y Y Y

On On On O O

25 ÷ 50 %

G Y Y Y Y

On On On On O

50 ÷ 75 %

G Y Y Y Y

On On On On On

75 ÷ 100 %

Selection of operating mode. To see the current

operation mode it is sucient to press button

(1) once.

To change operation mode press the button

for between 2 to 10 seconds until the current

conguration ashing, each time the button is

pressed all possible functions are scrolled cycli-

cally. Aer a few seconds without doing any

operation the circulator memorises the selected

mode and goes back to operation display.

Attention: e circulator has various built-in

operation modes, however the constant curve

operation mode must be selected according to

the following table.

Circulating pump LED Description

G Y Y Y Y

On On On O O

Do not use

G Y Y Y Y

On On On On O

Constant curve

speed 2

G Y Y Y Y

On On On On On

Constant curve

speed 3 (default

for Victrix EXA

24 X 1 ErP)

G Y Y Y Y

On On On O On

Constant curve

speed 4

Constant curve: the circulator operates maintain-

ing constant speed.

Selection button lock. e button has a feature

that locks its operation to prevent accidental

modications. To lock the control panel, it is

necessary to press button (1) for more than 10

seconds (during which the current conguration

ashes), the active lock is signalled by all LEDs of

the control panel ashing. To unlock the button

press again longer than 10 seconds.

Real time diagnostics: in the event of mal-

function the LEDs provide information on the

circulator operation status, see table (Fig. 1-28):

Loading...

Loading...