6-7

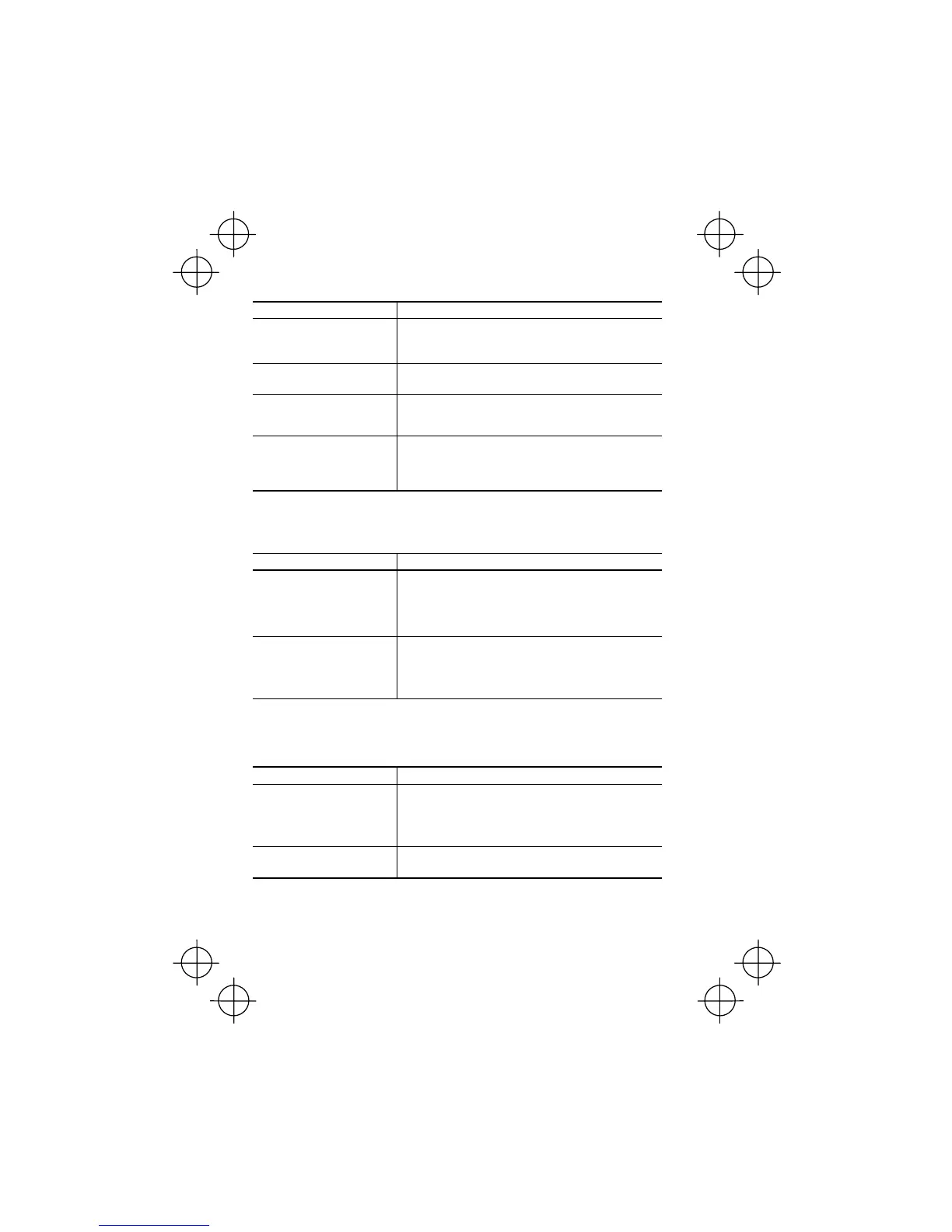

Possible Causes What to Check and Suggested Measures

(3) The automatic

deceleration was active.

Check the data of function code H69.

Î Consider the use of a braking resistor.

Î Increase the deceleration time (F08 and E11).

(4) Overload Measure the output current.

Î Reduce the load.

(5) Torque generated by the

motor was insufficient.

Check that the motor starts running if the value of the torque

boost (F09) is increased.

Î Increase the value of the torque boost (F09).

(6) An external frequency

command device is being

used.

Check that there is no noise in the external signal wires.

Î Isolate the control signal wires from the main circuit wires as

far as possible.

Î Use shielded wire or twisted wire for the control signal wires.

[ 7 ] Even if the power recovers after an instantaneous power failure, the motor does not

restart.

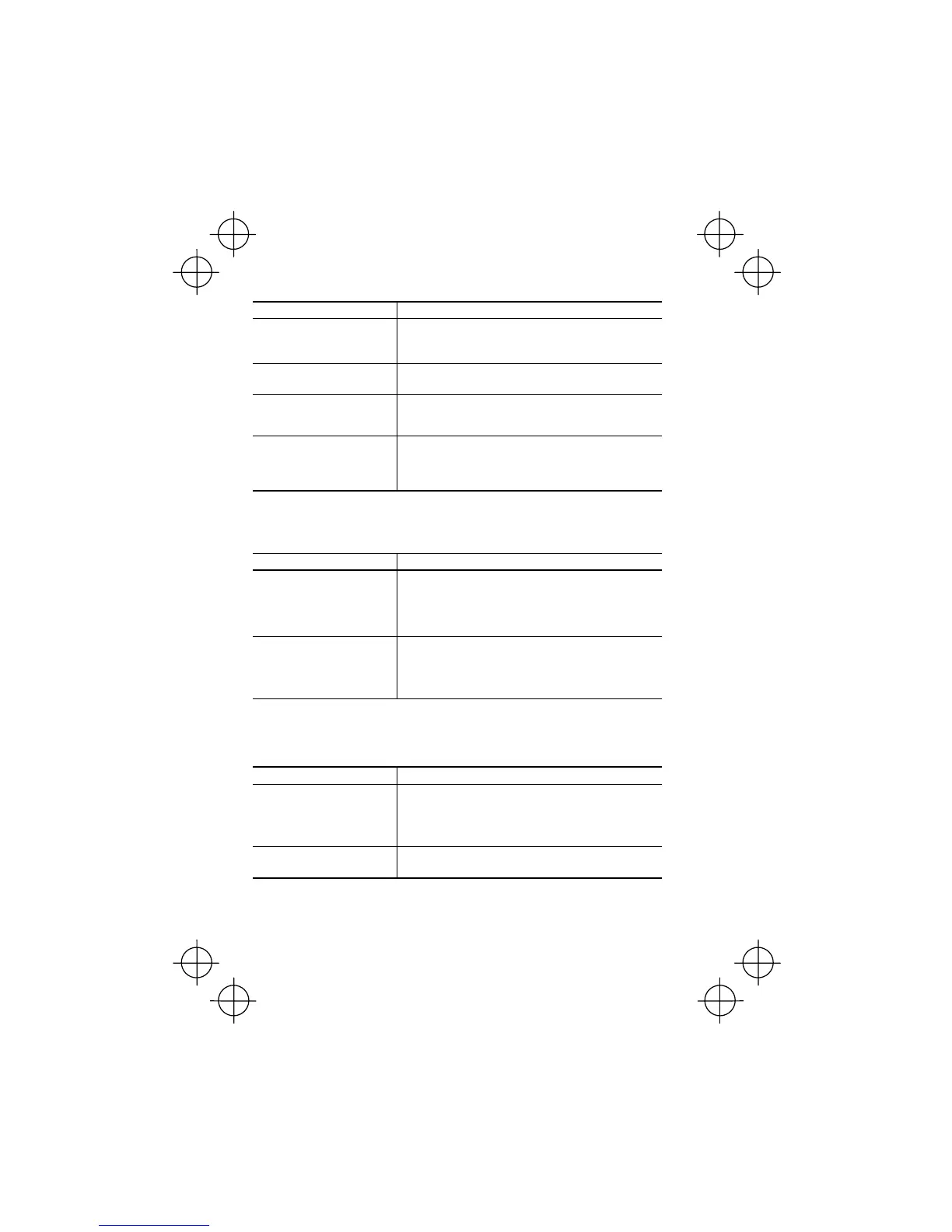

Possible Causes What to Check and Suggested Measures

(1) The setting of function

code F14 did not make the

motor restart even if the

power recovered after an

instantaneous power

failure.

Check if an undervoltage trip occurs.

Î Change the data of function code F14 to 4 or 5.

(2) The run command stayed

off even after the power

recovered.

Check the input signal with Menu #4 "I/O checking" using the

keypad.

Î Check the power recovery sequence with an external circuit.

If necessary, consider the use of a relay that can keep the

run command on.

6.2.2 Problems with inverter settings

[ 1 ] If the data of function codes cannot be changed

Possible Causes What to Check and Suggested Measures

(1) An attempt was made to

change function code data

that cannot be changed

when the inverter is

running.

Check if the inverter is running with Menu #3 "Drive monitoring"

using the keypad and then confirm whether the data of the

function codes can be changed when the motor is running b

Loading...

Loading...