2-4

(2) Arrangement of the control circuit terminals (common to all Jaguar CUB models)

Screw size: M 2 Tightening torque: 0.2 N•m

Screw size: M 2.5 Tightening torque: 0.4 N•m

30

C1 PLC

12 13 11 CM

X1 X2 X3

CM FWD REV

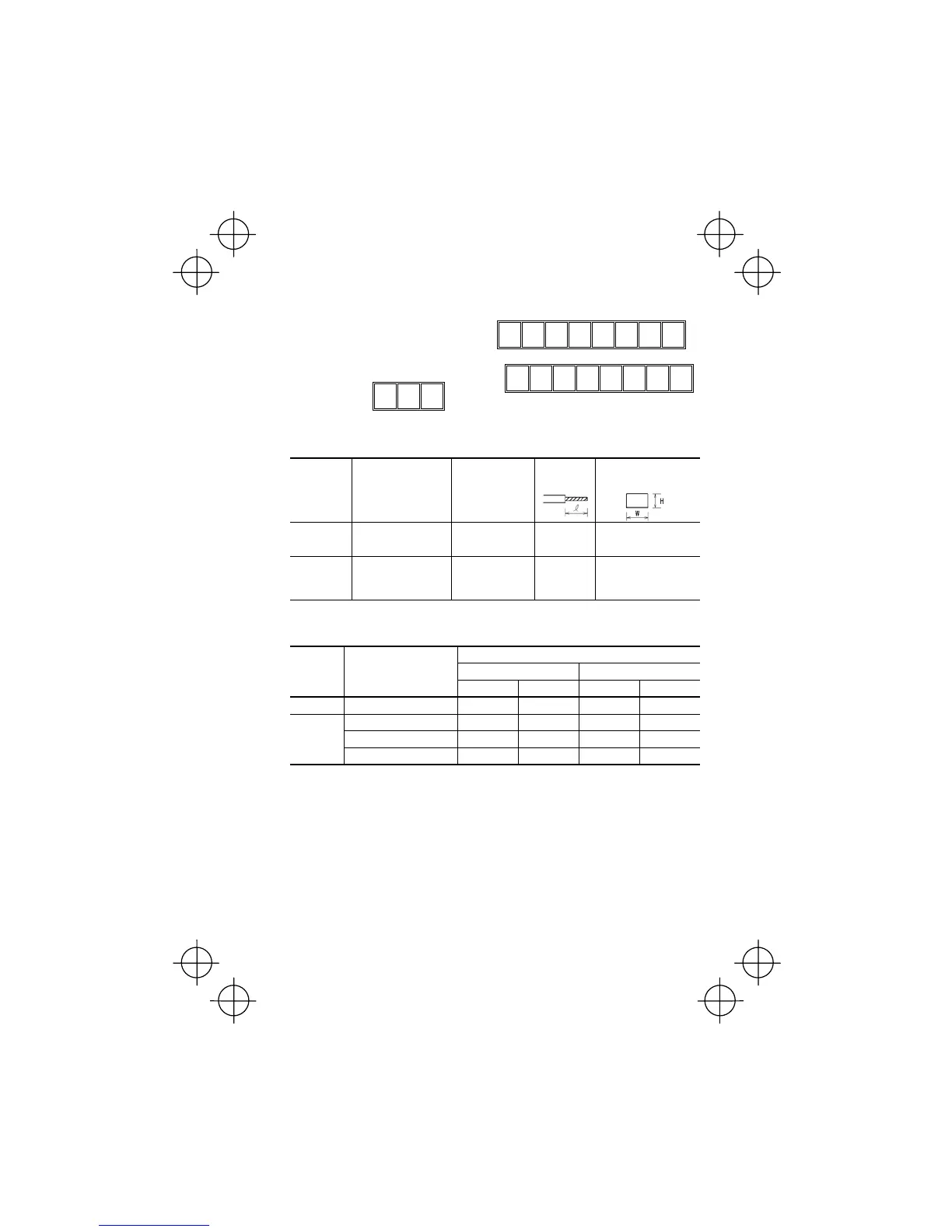

Table 2.4 Control Circuit Terminals

Terminal Screwdriver to be used Allowable wire size

Bared wire

length

Dimension of openings in

the control circuit termi-

nals for stick terminals*

30A, 30B, 30C

Phillips screwdriver

(JIS standard)

No.1 screw tip

AWG22 to AWG18

(0.34 to 0.75 mm

2

)

6 to 8 mm 2.7 mm (W) x 1.8 mm (H)

Others

Phillips screwdriver for

precision machinery

(JCIS standard)

No.0 screw tip

AWG24 to AWG18

(0.25 to 0.75 mm

2

)

5 to 7 mm 1.7 mm (W) x 1.6 mm (H)

* Manufacturer of stick terminals: WAGO Company of Japan, Ltd. Refer to Table 2.5.

Table 2.5 Recommended Stick Terminals

Type (216-

)

Screw size Wire size

With insulated collar Without insulated collar

Short type Long type Short type Long type

M2

AWG24 (0.25 mm

2

) 321 301 151 131

AWG22 (0.34 mm

2

) 322 302 152 132

M2 or M2.5

AWG20 (0.50 mm

2

) 221 201 121 101

AWG18 (0.75 mm

2

) 222 202 122 102

The length of bared wires to be inserted into stick terminals is 5.0 mm or 8.0 mm for the short or long type,

respectively.

The following crimping tool is recommended: Variocrimp 4 (Part No.: 206-204).

2.3.3 Recommended Wire Sizes

Table 2.6 lists the recommended wire sizes. The wire size for the main circuit denotes the values for

HIV and IV solid wires proceeding and following a slash (/), respectively, at an ambient temperature

of 50qC.

Loading...

Loading...