WARNING

Any Anti Two Blocking System consists of a

series of mechanical components and cannot

be 100% fail safe.

Do NO T use the Anti Two Block System as a

substitute for good judgement, experience

and accepted safe crane operating practices.

With untrained or inexperienced operators, two blocking the winch cable is a very likely

possibility. When the winch cable end attachments contact the underside of the sheave case,

whether by winching up or by extending the boom without paying out winch cable, the winch

cable can be damaged by crimping or over-tensioning. The sheave may also be damaged.

An anti two blocking system can help prevent cable damage by sensing the position of the winch

cable end attachments with respect to the sheave case and shutting down the functions that

cause two blocking.

Restore normal crane function by winching down or retracting the boom until the anti two block

weight is once again suspended freely.

Inspect the anti two block system daily as follows:

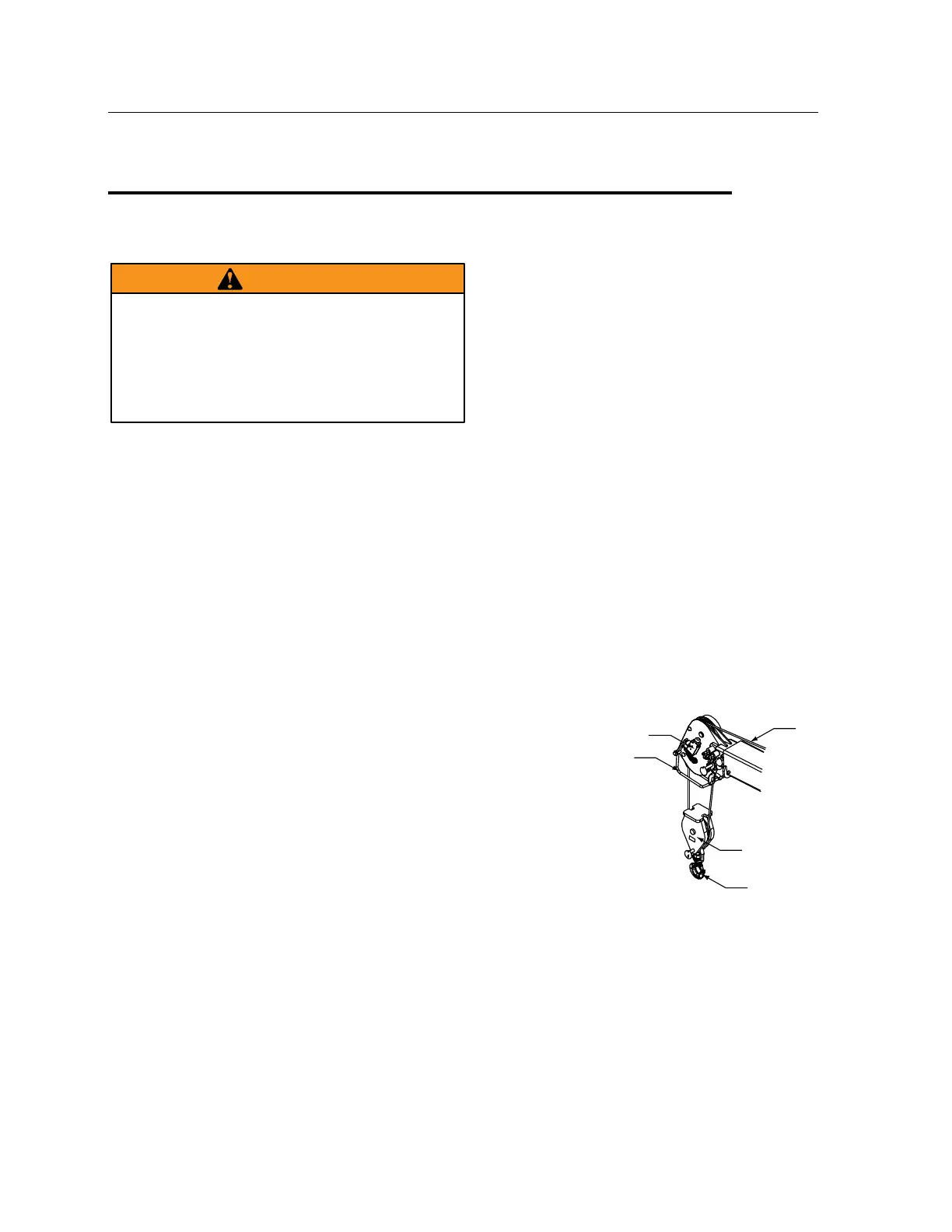

1 Examine switch activation mechanism to insure free

unrestricted mechanical operation

2 Examine cord for damage, cuts or breaks. Grasp cord

and pull to check operation of cord reel. The cord

should retract on reel when released.

3 Slowly winch loadline up until anti two block weight

comes in contact with the hook end of the loadline

cable. At the moment the weight is fully supported,

the winch up function should stop functioning and

have no pull capability. If anything else happens, stop

and reverse the function. Failure to do so will risk

damage to the cable or the crane.

4 If the winch up function works properly, actuate the

boom extend function slowly. Gradually increase to

full actuation. The boom extend function should be

non-existent with no tightening of the winch cable. If

anything else happens, stop and reverse the function.

Loading...

Loading...