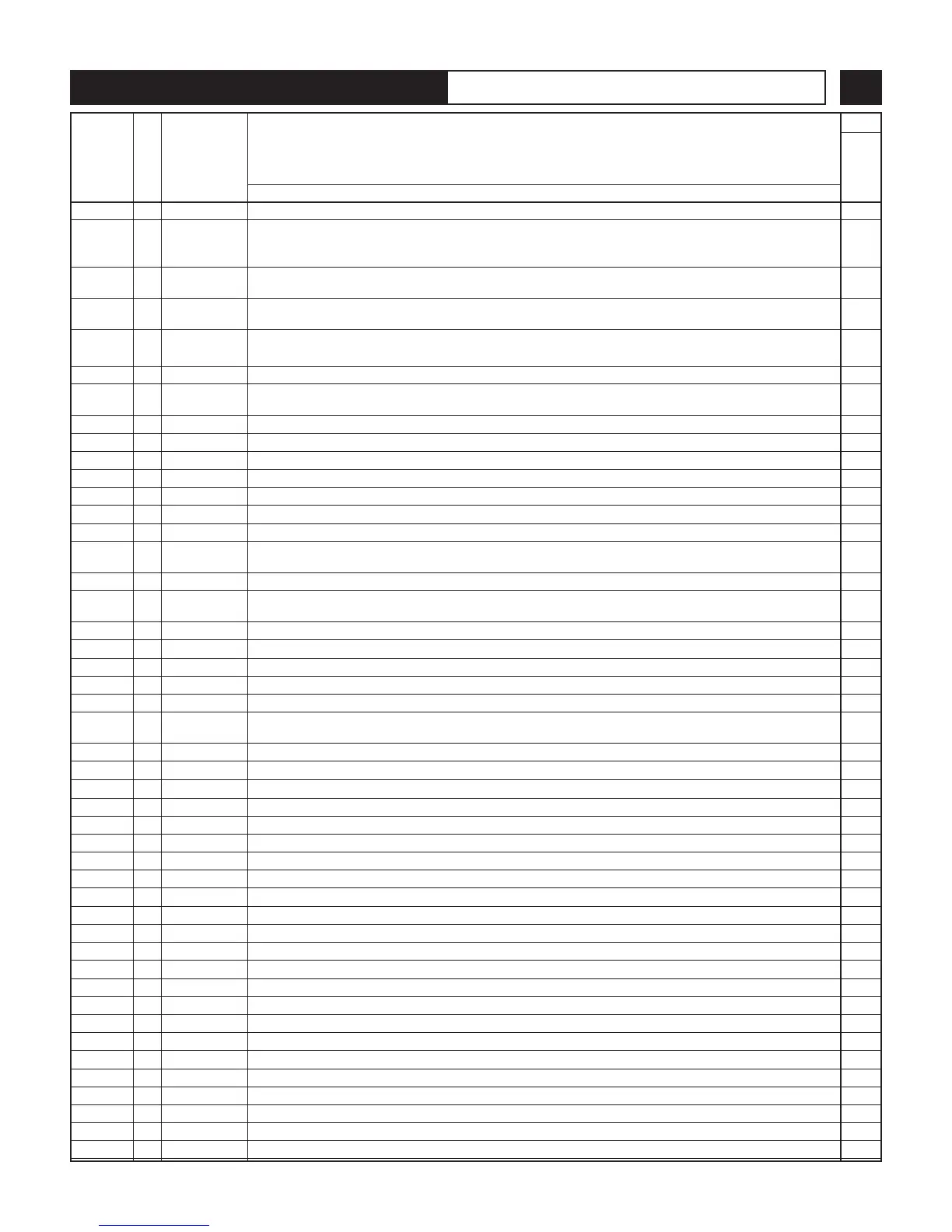

6-3 SECTION 6. GENERAL REFERENCE99903514:TELESCOPIC CRANE:

D 14 Tires Check tires (when in use) for proper inflation and condition.

D 15 Ground Ground conditions around the equipment for proper support, including ground settling under and

conditions around and around stabilizers and supporting foundations, ground water accumulation,

or similar.

D 16 Level Position The equipment for level position within tolerances specified by the equipment manufacturer’s

recommendations, both before each shift and after each move and setup.

D 17 Operator Cab Significant cracks, breaks, or other deficiencies that would hamper the operator’s view.

Windows

D18Rails, rail stops, Rails, rail stops, rail clamps and supporting surfaces when the equipment has rail traveling.

clamps, supporting

surfaces.

D19Safety Devices Safety devices and operational aids for proper operation.

D 20 Electrical Electrical apparatus for malfunctioning, signs of apparent excessive deterioration, dirt or moisture

accumulation.

D 21 Other

D 22 Other

M 23 Daily All daily inspection items.

M 24 Cylinders Visual inspection of cylinders for leakage at rod, fittings & welds. Damage to rod & case.

M 25 Valves Holding valves for proper operation.

M 26 Valves Control valve for leaks at fittings & between sections.

M 27 Valves Control valve linkages for wear, smoothness of operation & tightness of fasteners. Relief valve for

proper pressure settings.

M 28 General Bent, broken or significantly rusted/corroded parts.

M 29 Electrical Electrical apparatus for malfunctioning, signs of apparent excess deterioration, dirt or moisture

accumulation. Electrical systems for presence of dirt, moisture and frayed wires.

M 30 Structure All structural members for damage.

M 31 Welds All welds for breaks & cracks.

M 32 Pins All pins for proper installation & condition.

M 33 Hardware All bolts, fasteners & retaining rings for tightness, wear & corrosion

M 34 Wear Pads Condition of wear pads.

M 35 Pump & Motor Hydraulic pumps & motors for leakage at fittings, seals & between sections. Check tightness of

mounting bolts.

M 36 PTO Transmission/PTO for leakage, abnormal vibration & noise, alignment & mounting bolt torque.

M 37 Hyd Fluid Quality of hydraulic fluid and for presence of water.

M 38 Hyd Lines Hoses & tubes for leakage, abrasion damage, blistering, cracking, deterioration, fitting leakage & secured properly.

M 39 Hook Load hook for abnormal throat distance, twist, wear & cracks.

M 40 Wire Rope Condition of load line.

M 41 Manual Presence of operator’s manuals with unit.

M 42 Other

M 43 Other

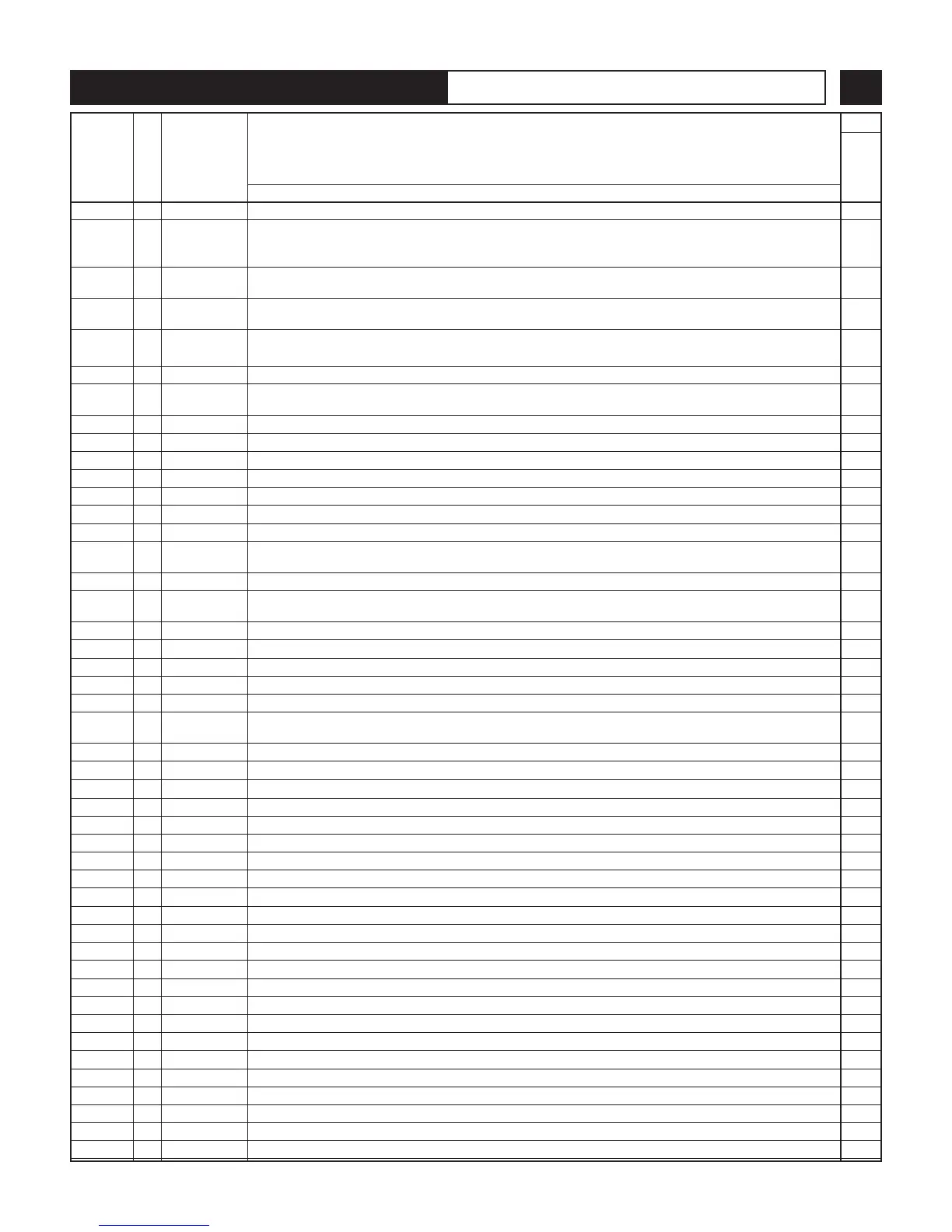

Q 44 Daily All daily inspection items.

Q 45 Monthly All monthly inspection items.

Q 46 Rotation Sys Rotation bearing for proper torque of all mounting bolts.

Q 47 Hardware Base mounting bolts for proper torque.

Q 48 Structure All structural members for deformation, cracks & corrosion.

49 l Base

50 l Stabilizer beams & legs

51 l Mast

52 l Inner boom

53 l Outer boom

54 l Extension(s)

55 l Jib boom

56 l Jib extension(s)

57 l Other

Q 58 Hardware Pins, bearings, shafts, gears, rollers, & locking devices for wear, cracks, corrosion & distortion.

Inspection Checklist

CRANES

2

STATUS

FREQUENCY

INSPECTION DESCRIPTION

KEYITEM

20111122

, R,

X, NA

= SATISFACTORY

R = RECOMMENDATION (Should be

considered for corrective action)

NA = Not Applicable

X = Deficient (Note: If a deficiency is found, an immediate

determination must be made as to whether the deficiency

constitutes a safety hazard and must be corrected prior to

operation.)

Loading...

Loading...