99903514:TELESCOPIC CRANE:

2-6 SECTION 2: MAINTENANCE

2-5: HYDRAULIC SYSTEM

2-5-1: HYDRAULIC OIL SPECIFICATIONS

The hydraulic oil is the power transmission

medium, system lubricant, and coolant. Under

normal operation conditions, the hydraulic oil

must meet the following specifications:

High quality, antiwear hydraulic oil which

meets ISO VG 32.

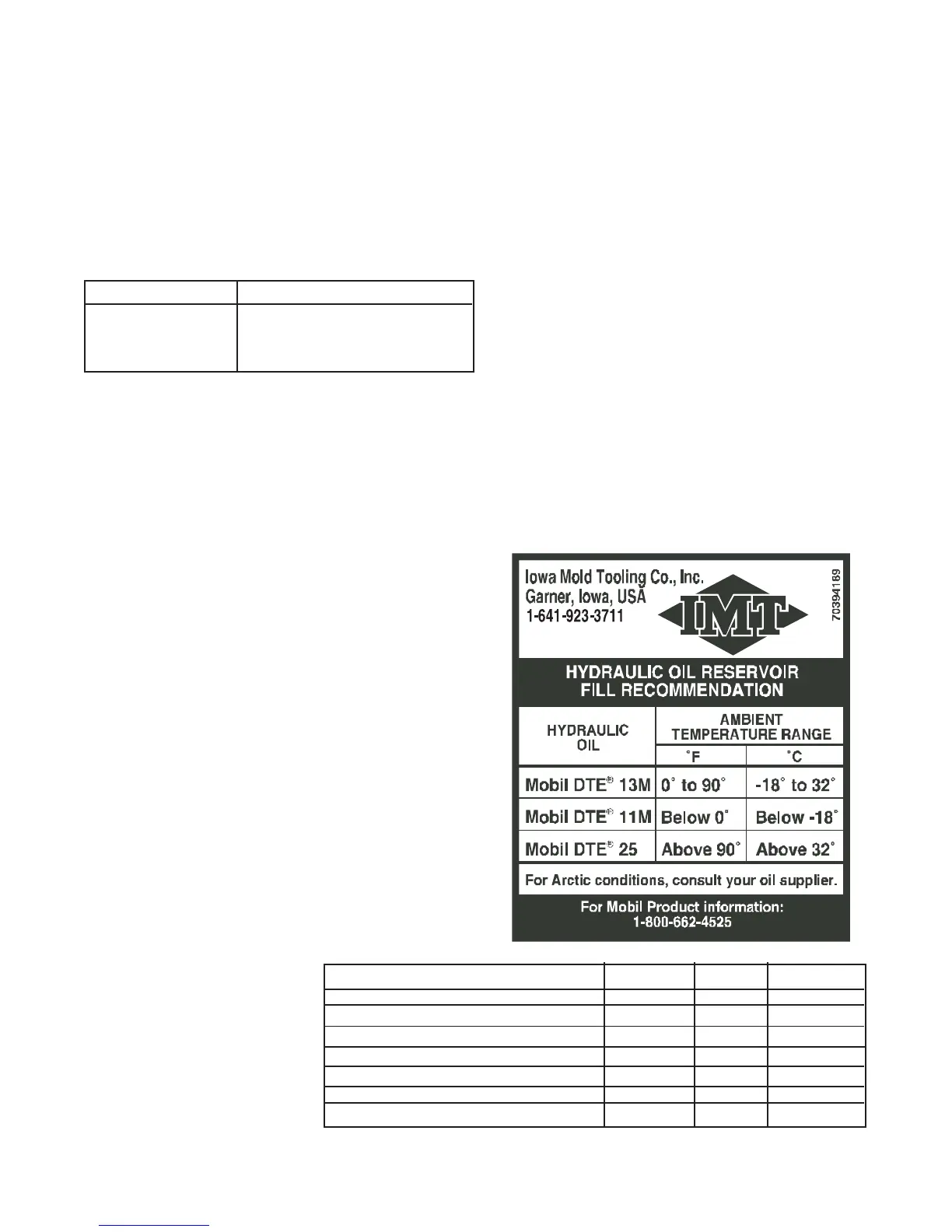

Viscosity specifications for hydraulic oil:

AMBIENT TEMPERATURE RANGE 0-90° BELOW 0° ABOVE 90°

Minimum Pour Point, °F -40° -40° -10°

Maximum Viscosity, SSU @ 0°F 5000 1500 —-

Minimum Viscosity, SSU @ 100°F 140-195 80-90 200-335

Minimum Viscosity, SSU @ 210°F 48 39 49

Minimum Viscosity Index 139 139 95

ISO VG Grade 32 15 46

Mobil Oils (Reference) DTE 13M DTE 11M DTE 25

Viscosity characteristics including:

1. 80 to 180 SSU optimum at system operating

pressure.

2. 60 SSU minimum at system operating

temperature.

3. 7500 SSU maximum at starting tempera-

ture.

4. 90 Viscosity Index (VI) minimum.

Additives including anti-foam inhibitors, anti-

oxidant inhibitors, rust resistance, and anti-wear

must be part of the oil.

When the crane leaves the factory, it is filled

with an ISO VG32, low pour, anti-wear hydraulic

oil.

2-5-2: LOW TEMPERATURE HYDRAULIC

OIL SPECIFICATIONS

In conditions below -25°F, use gear oil which

meets MIL-L-2105C Grade 75W (GO-75).

Fluids which contain halogenated hydrocarbons,

nitro hydrocarbons, and phosphate ester hy-

draulic fluids may not be compatible with hy-

draulic system seals and wear bands.

2-5-3: HYDRAULIC FLUID LEVEL

Check the hydraulic oil level daily using the

following procedure:

1. Remove the hydraulic oil reservoir cap.

2. Visually check the oil level. Oil should be

visible in the fill screen area above the bottom of

the reservoir.

3. If the hydraulic oil is low, fill until the oil is

visible in the screen area.

SAE Designation Temperature Range

5W-20 -10 to 180°F (-23 to 82°C)

10W +10 to 180°F (-12 to 82°C)

10W-30 +10 to 210°F (-12 to 99°C)

Figure B-8: SAE Designation for

Hydraulic Oil

Figure B-9: Hydraulic Fluid Specifications

20030115

Loading...

Loading...