99903514:TELESCOPIC CRANE: 4-5

SECTION 4: INSTALLATION

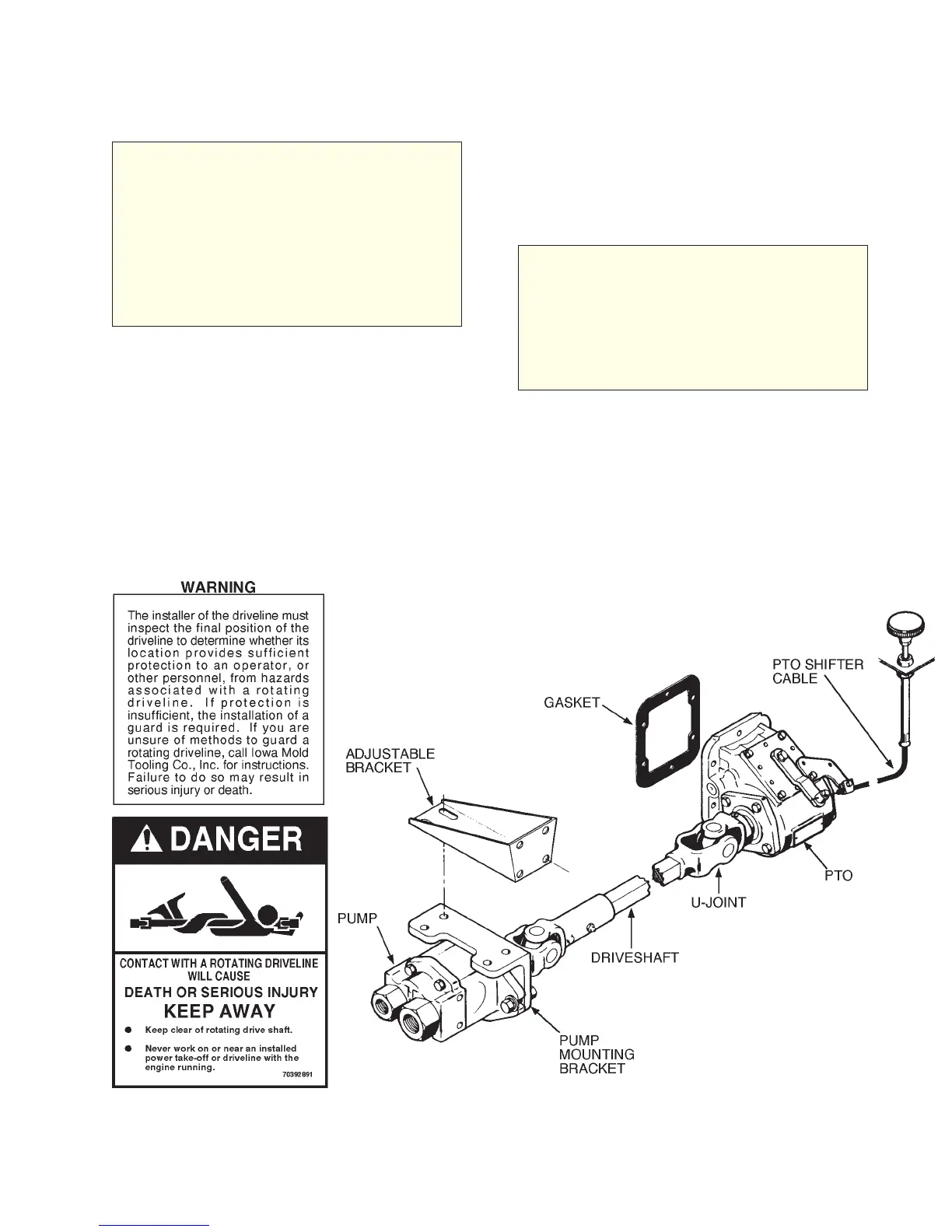

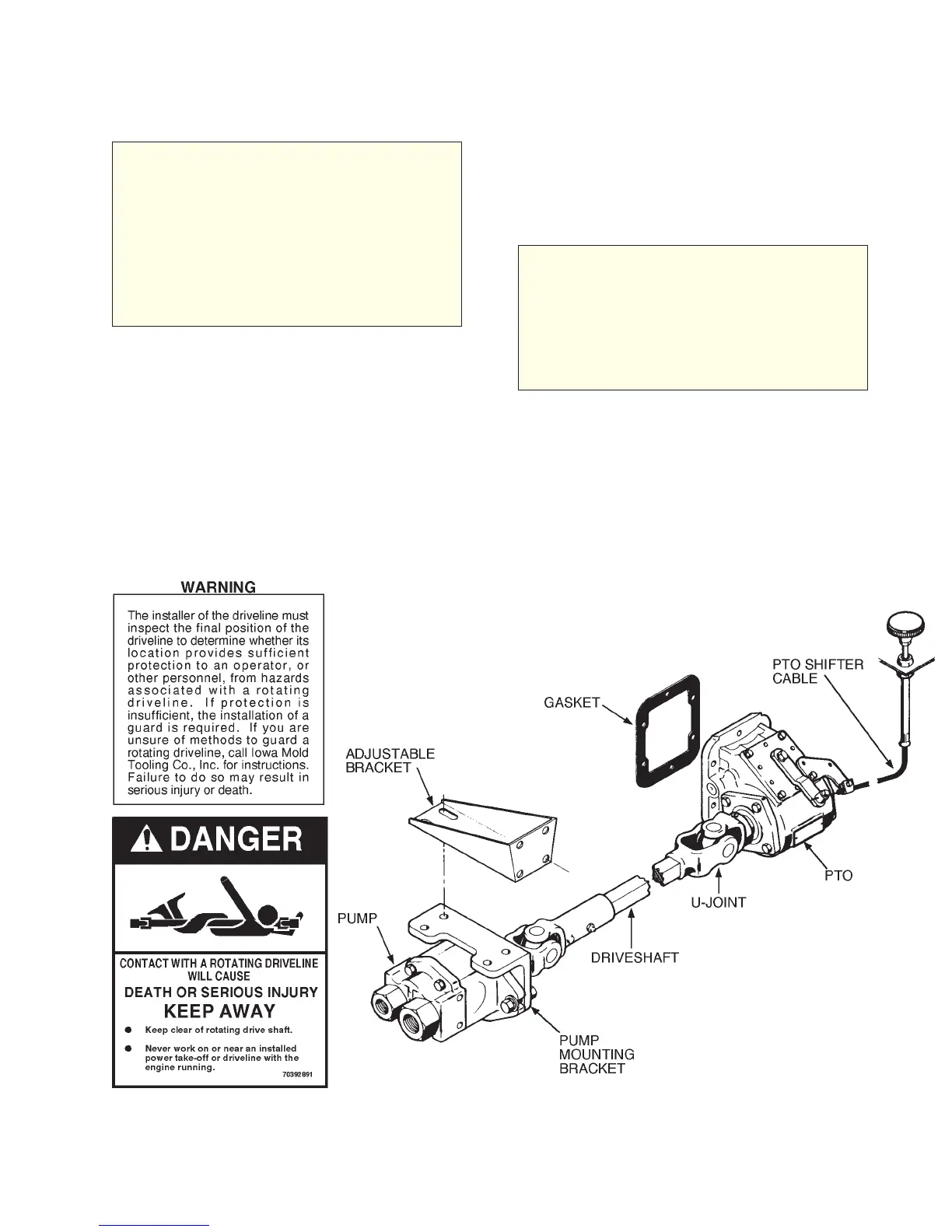

Driveshaft installation guidelines:

WARNING

DRIVESHAFTS ARE DANGEROUS!

PLACE DRIVESHAFT IN AN UNEX-

POSED OR SHIELDED POSITION TO

HELP PREVENT ACCIDENTAL EN-

TANGLEMENT. FABRICATION OF A

SHIELD OR FENCE TO ISOLATE RO-

TATING DRIVESHAFTS WILL HELP

PREVENT PERSONAL INJURY OR

DEATH.

1. Install the PTO per manufacturer’s in-

structions.

2. Loosely bolt the pump mounting bracket to

the adjustable bracket.

3. Bolt the adjustable bracket to the truck

frame at a point not exceeding 48" (121.9cm)

from PTO and where it will not produce a joint

angle greater than that recommended by the

manufacturer.

4. Check pump rotation and install pump,

pumpend yoke and PTO end yoke.

5. If a setscrew protrudes above end yoke

hub, replace it with a recessed allen-head set

screw.

WARNING

A PROTRUDING SET SCREW OR

OTHER HARDWARE IS HAZARDOUS

TO PERSONNEL. WHEN THE

DRIVESHAFT IS SPINNING, IT PRO-

VIDES A HOOK TO SNAG CLOTHING,

SKIN AND HAIR, RESULTING IN PER-

SONAL INJURY OR DEATH.

6. Size, cut and weld the driveline per

manufacturer’s instructions.

7. Install driveline and lock set screws,

torqueing all fasteners as recommended.

8. Lubricate driveshaft per manufacurer’s

recommendations.

Figure D-4: Driveline Application

20030115

Loading...

Loading...