General Information 108 Section - 6

4004i - Manual # 99904386

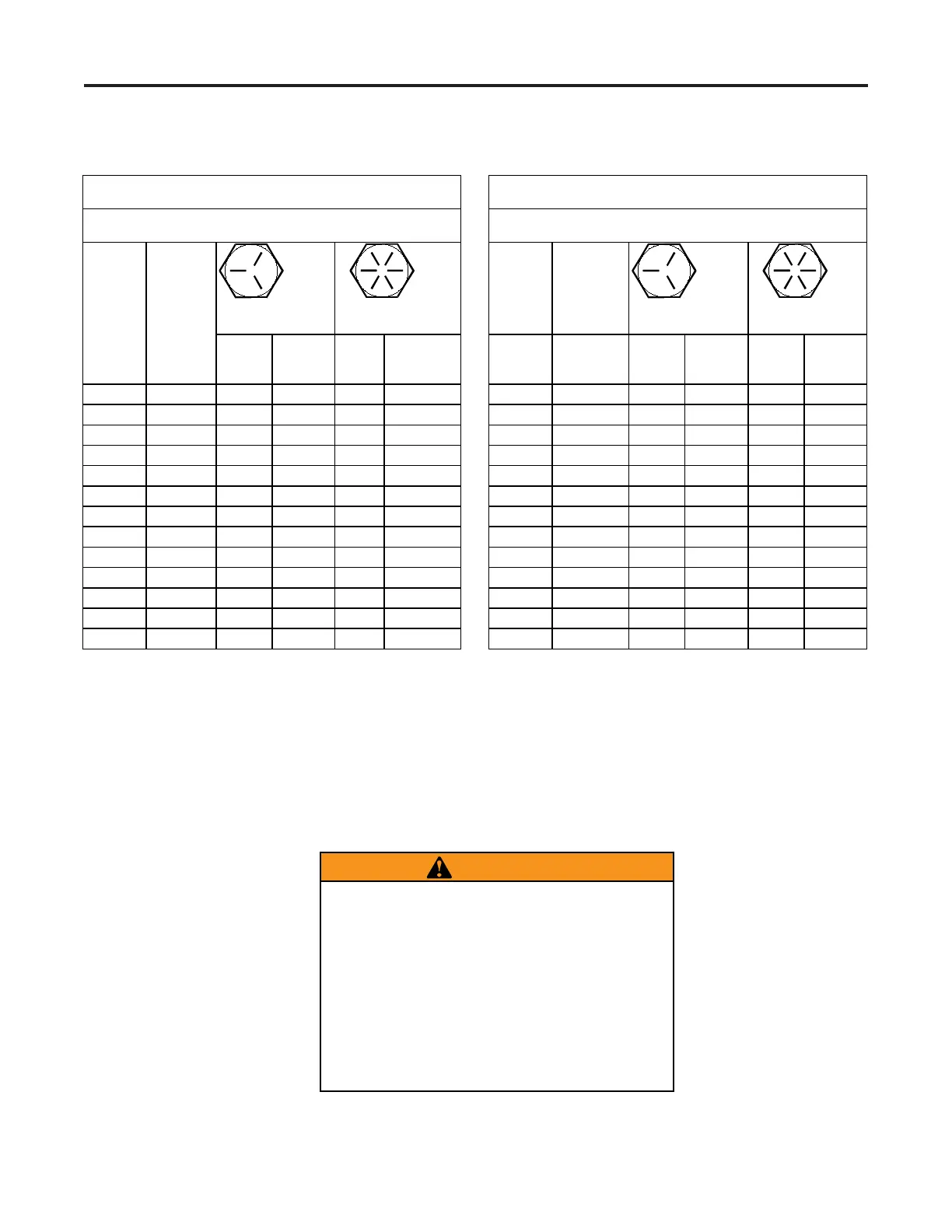

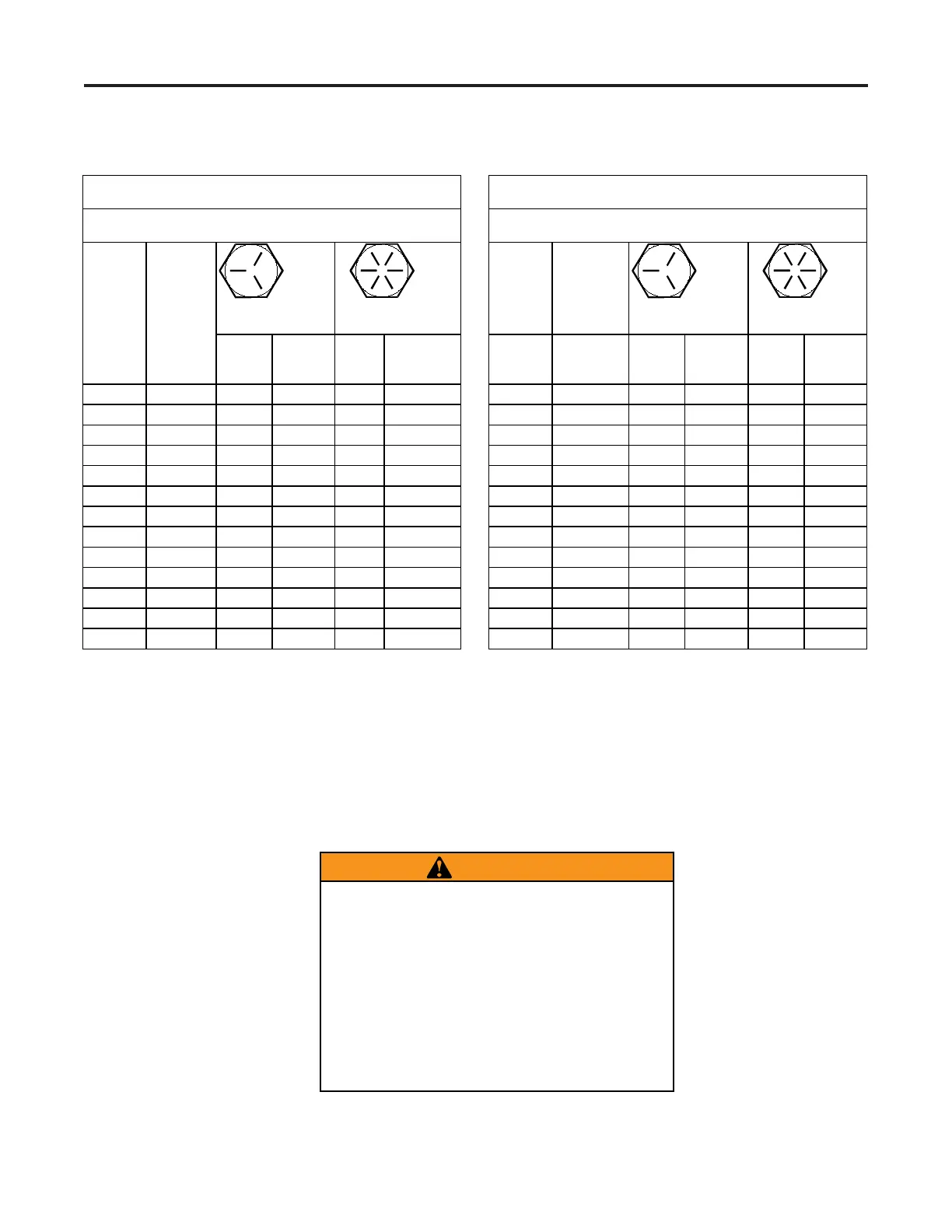

Torque Charts (Metric)

NOTES:

1. Tightening torques provided are mid-range.

2. Consult bolt manufacturers particular specications.

3. Use at washers of equal strength.

4. Alltorque measurements are given in both KG-M and FT- LB.

5. Torque values specied are for bolts with residual oils or no special lubricants applied. If

special lubricants of stress ability, such as never-seez compound, graphite, oil, molybdenum

disulde, colloidal copper, or white lead are applied, mulitply the torque values in the charts

by the factor .90. The use of loctite does not aect the torque values listed above.

FINE THREAD TORQUE CHART (METRIC)

COARSE THREAD TORQUE CHART (METRIC)

(DIA-

TPI)

DIA.

(INCHES)

SAE J429

SAE J429

(DIA-

TPI)

(INCHES)

SAE J429

SAE J429

(KG-M)

(KG-M)

(KG-

(KG-M)

(KG-M)

(KG-M)

(KG-M)

(KG-M)

WARNING

Anytime a gear-bearing bolt is removed, it

must be replaced with a new bolt of the

identical grade and size. Once a bolt has

been torqued to 75% of its proof load and

then removed, the torque coe fficient may no

longer be the same as when the bolt was new

thus giving indeterminate clamp loads after

torqueing. Failure to replace gear-bearing

bolts may result in bolt failure due to metal

fatigue causing death or serious injury.

Loading...

Loading...