Oshkosh Corporation Classification: Unrestricted

Chapter 4 Maintenance & Repair 39

2 Make sure the crane power disconnect cable is disconnected from the vehicle battery.

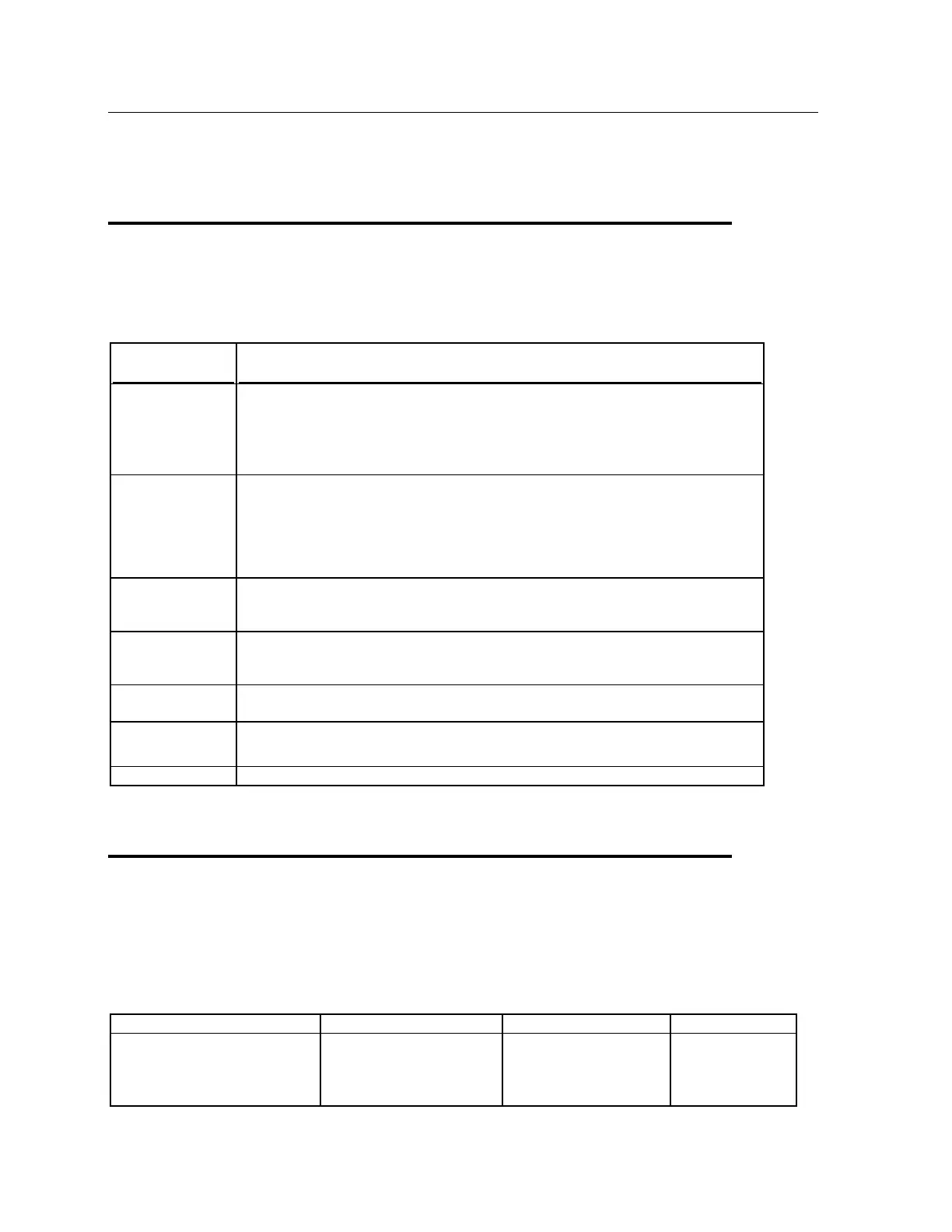

Maintenance Schedule

Detailed steps on numerous maintenance procedures are described in the following pages. Use

the following chart to help you determine the time schedule of the maintenance requirements.

Lubricate:

▪ Grease Zerks

▪ Hinge Pins

▪ Turntable Bearing

Lubricate:

▪ Worm gear bearings

▪ PTO

Complete all required monthly inspections. (See IMT Inspection Checklist

in the General Reference section of this manual.)

After the first 50

hours of service

Complete all required quarterly inspections. (See IMT Inspection Checklist

in the General Reference section of this manual.)

Every 6 months

or 800 hours

Purge hydraulic system and replace hydraulic oil and filter.

Complete all required annual inspections. (See IMT Inspection Checklist in

the General Reference section of this manual.)

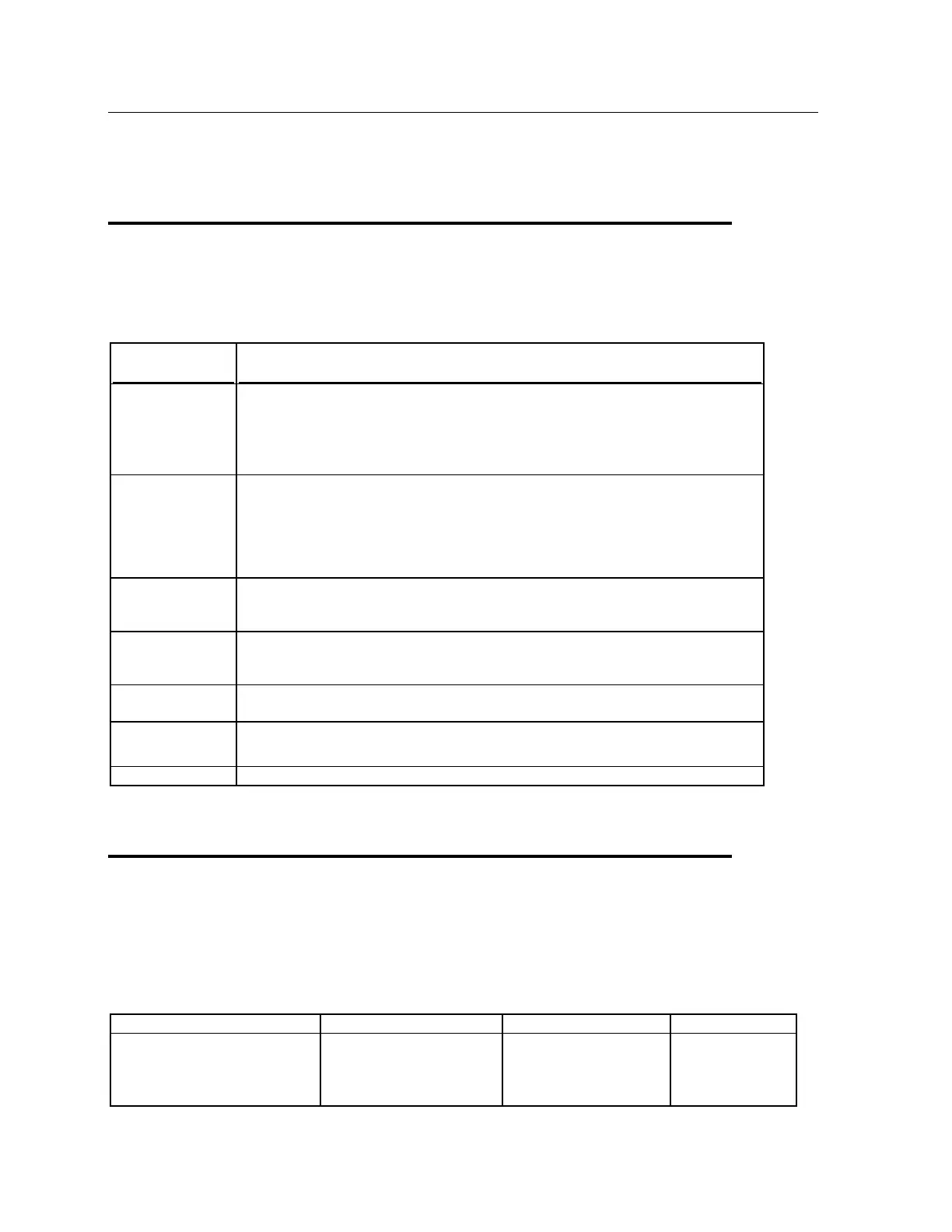

Electric Crane Lubrication

Different lubricants are required for different sections of your crane. Contact your lubricant

supplier for specific product information.

Follow the grease and lubricant specifications and intervals listed in this manual for best results.

Turntable Bearing (rotate

while greasing)

Cylinder Pins

Boom Hinge Pins

Shell Alvania 2EP or

Shell Retinax "A" or

Mobilith AW2 or

equivalent

Hand Grease Gun or

Pneumatic Pressure

Gun

Loading...

Loading...