Aligning

and

Tuning

Best results always come from

machines

which are correctly

aligned

and

tuned

.

These

are

the

important

areas on which

we

recommend

periodic

checking

.

A.

Saw

blade

and

fence

parallel

to

the

mitre

guide

slots

B.

Blade

angle

stops

at

45°

and

90°

C.

Blade

angle

scale

D.

Splitter

and

guard

E.

Table

insert

plate

Alchough chese areas are aligned

ac

rhe facrory, mi

sa

lignmenc may occur

during

shipments,

and/or

afcer some period

of

use.

You

don'c need expensive cools

co

align and resc, buc you will need a good

cry

or

combination

square.

A good

cry

square wich a

3"-6"

blade will work nicely.

Test

the

square

on che oucside firsc. Some carpenters squares are

noc

accurate boch inside and outside.

Note:

All

adjustments

should he

made

with

the

saw

unplugged

for

safety.

DO

NOT

WORK

WHILE

:

A.

TIRED

B.

DRINKING

ANY

ALCOHOL

C.

DISTRACTED

D.

WEARING

LOOSE

CLOTHING

OR

TIES

DO

NOT

WORK

WITH:

A.

SAWDUST

ON

THE

FLOOR

B. LOOSE ELECTRICAL

CONNECTIONS

C.

LOOSE

WIRES

ON

THE

FLOOR

Belt

Tension

and

con

di

ti

on

The

drive belc has a break-in period. Afcer some hours

of

use

it

may loosen

and need

co

be censioned

in

order

co

gee full power from rhe mocor

wichour

slipping

.

1.

Unplug

the saw.

2. Tilcing che arbor for easier access.

3. Loosen rhe four boles which hold

the

mocor in place.

4.

Tighren

rhe sockec head screws in

the

ends

of

che tension bracket even-

ly

,

going

from one screw

co

che ocher,

making

only small

(Ya

turn)

adjusrmencs.

5.

When

you feel you have achieved correcc tension,

righten

the

four boles

char hold che mocor in place.

6.

Rorace che

blade

by hand

co

make sure the belc

is

nor

rubbing

or scrap-

tng.

7. Reconnect

the

power

and jog che

machine

on (on

and

off

quickly)

co

make sure chc blade

is

curning

in chc

ri

g

hc

direccion.

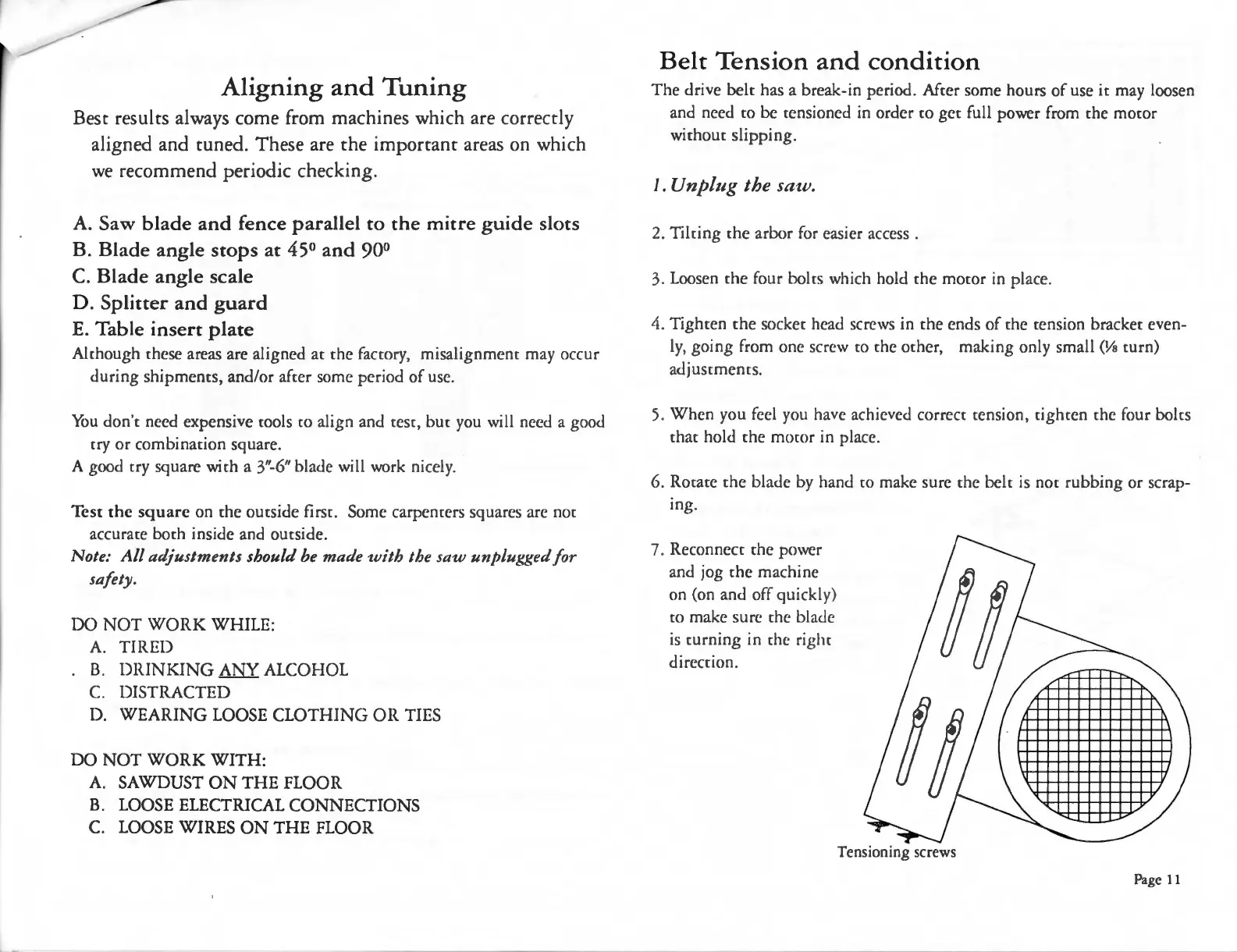

Tensioning screws

/

'\

-

/

"'

-

~

"'

\

I

IJ

......

Page

11

Loading...

Loading...